A system for comprehensive performance testing of fan filter unit

A comprehensive performance test, fan filter unit technology, applied in mechanical equipment, machines/engines, non-variable-capacity pumps, etc., can solve the problem of inability to balance between acoustic testing and aerodynamic performance testing, and achieve reliable test results and easy installation. , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

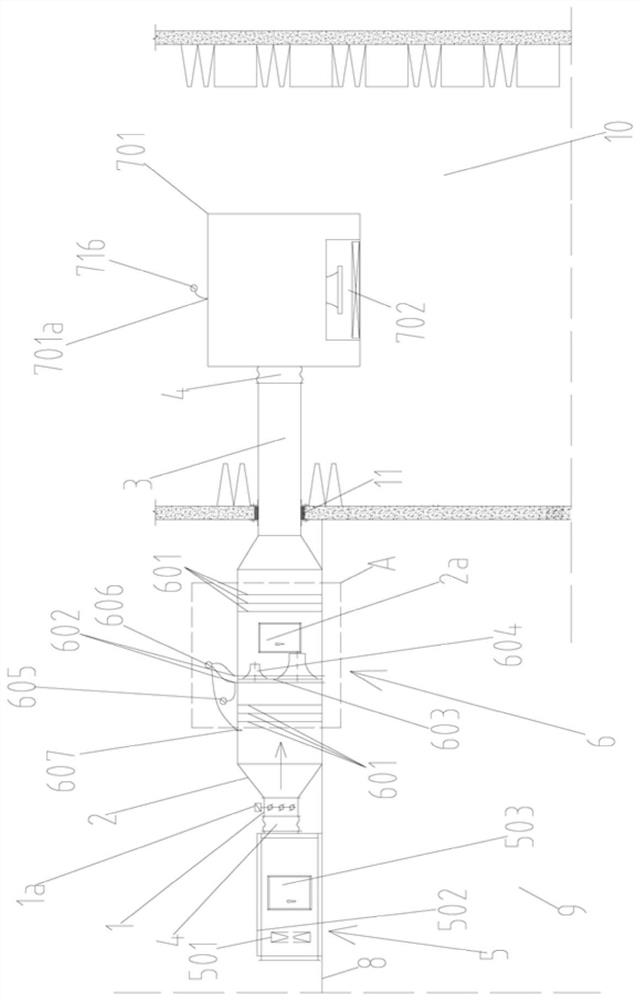

[0041] combine figure 1 , 2 , 5, a system for comprehensive performance testing of fan filter units, including the following parts:

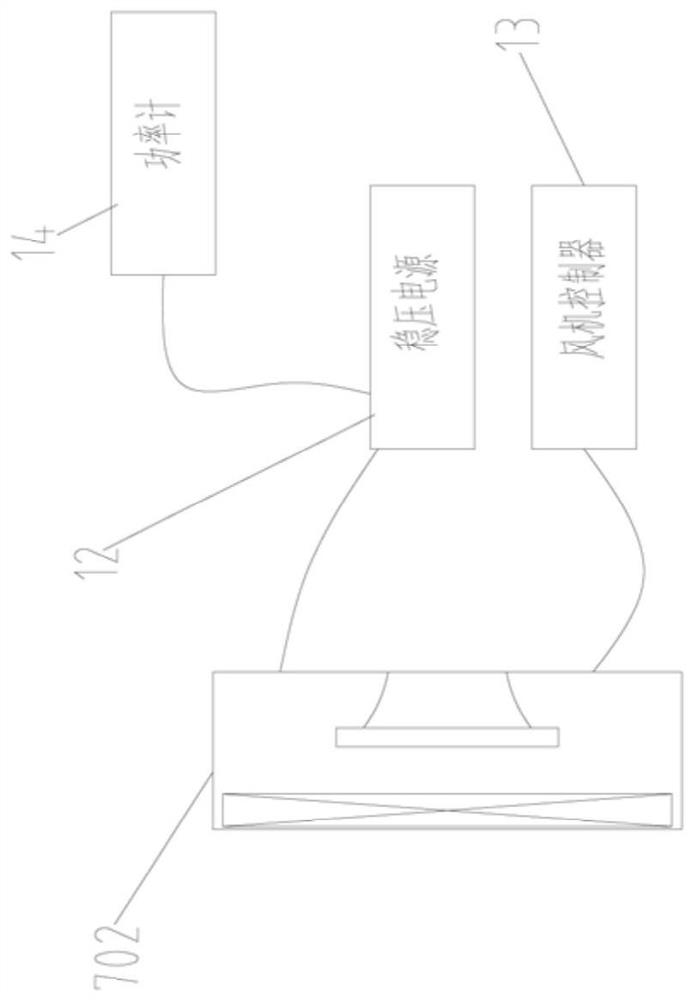

[0042] Computer 15, capable of controlling the tested FFU702;

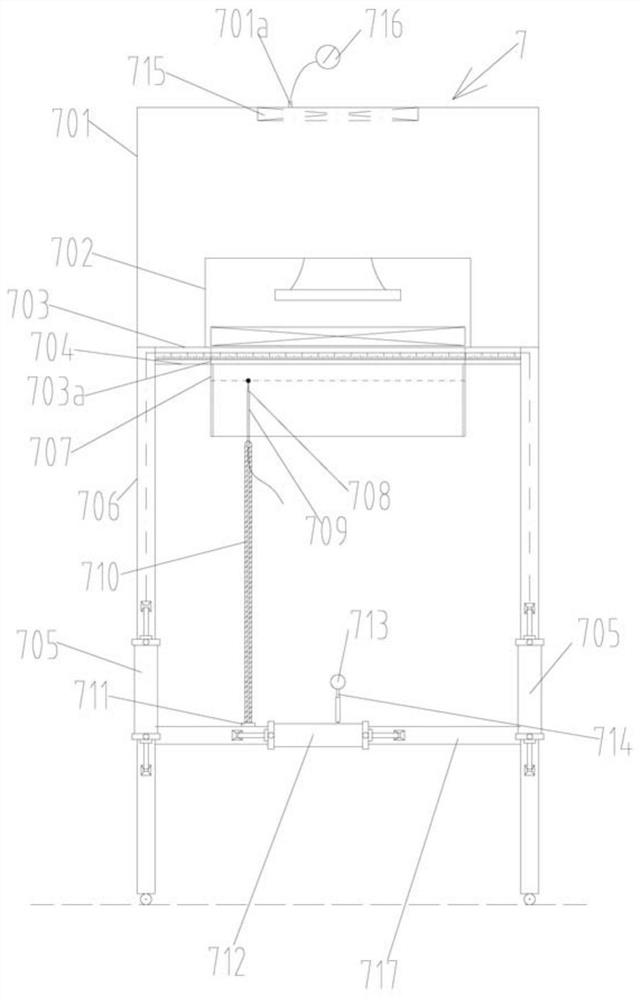

[0043] The surface wind velocity measuring part 7 is used to measure the performance parameters of the tested FFU702, and has a static pressure box body 701 that can accommodate the tested FFU702;

[0044] The anechoic laboratory 10 is used to accommodate the plenum box body 701 and the surface wind velocity measurement component 7;

[0045] Fan part 5 controlled by computer 15;

[0046] The air volume measuring part 6 controlled by the computer 15; and

[0047] It is used to introduce the outside atmosphere into the plenum box body 701 and seal the air induction pipeline connected to the wall of the anechoic laboratory 10. The air inlet end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com