Continuous punching and hole flanging blanking die

A hole-turning and blanking technology, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of workpiece coaxiality, difficulty in meeting the precision requirements, long period of mold replacement and debugging, and low utilization rate of equipment, etc., to achieve Improve work efficiency and product accuracy, reduce equipment investment costs, and achieve good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following will be further described in conjunction with the accompanying drawings, not to limit the scope of the present invention.

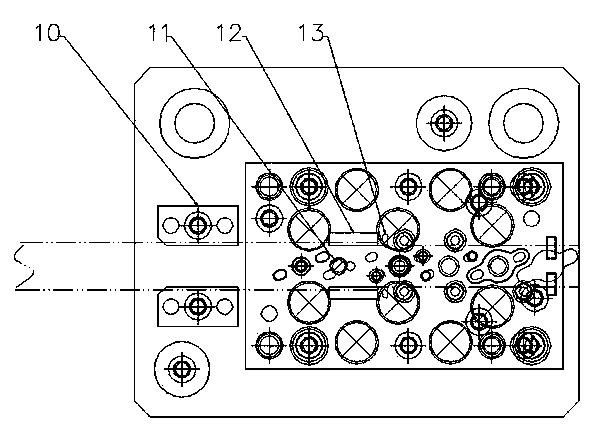

[0016] see figure 1 and figure 2 Shown, the present invention comprises upper formwork 3, punch and lower formwork 8, is fixed with mold handle 1, spring 2, punch fixed plate 4, binder plate 5 on upper formwork 3, fixes convex mold in described fixed plate Dies, on the lower template 8 are provided with a floating tip 6, a die 7 and a material guide plate 10, and on the die 7 are provided with an initial positioning pin 11, a side edge 12 and a step positioning block 13. The guide post guide sleeve 9 is arranged on the upper template 3. When working, put the workpiece between the two material guide plates 10 and push it forward to the initial positioning pin 11. When the upper mold is pressed in, the punching is completed; Push forward to the step distance positioning block 13, which is exactly one step distance. When the upper die...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com