Process for stamping and forming sedan car rear auxiliary frame body

A technology of rear sub-frame and stamping forming, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of low stability of parts, high input cost, complex shape, etc., to improve production efficiency and equipment cost. low, high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

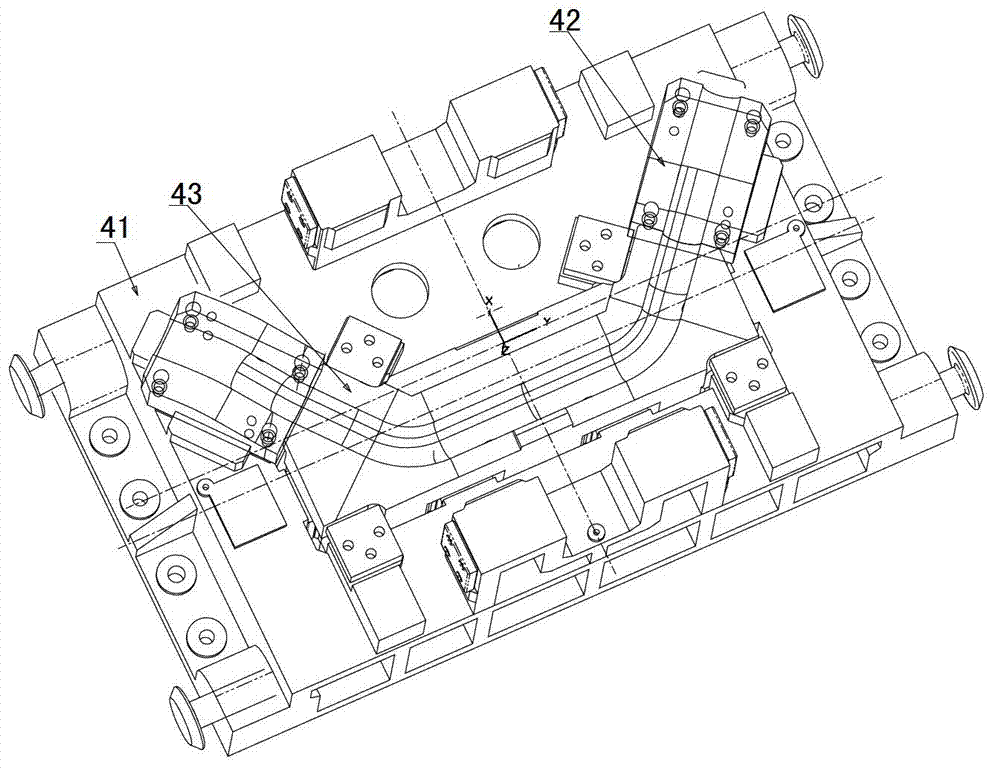

[0027] see Figure 1 to Figure 10 , the stamping forming process of the main body of the rear sub-frame of a car in the present invention uses a section of seamless steel pipe equivalent to the unfolded length of the main body of the rear sub-frame of a car as a raw material, and is bent into an approximate shape having the finished product of the main body of the rear sub-frame of a car as a raw material. The workpiece is processed, including the following five processes:

[0028] Step 1: Use the first set of molds to shape the two corners of the workpiece, so that the angle and radian of the two corners fully meet the design requirements.

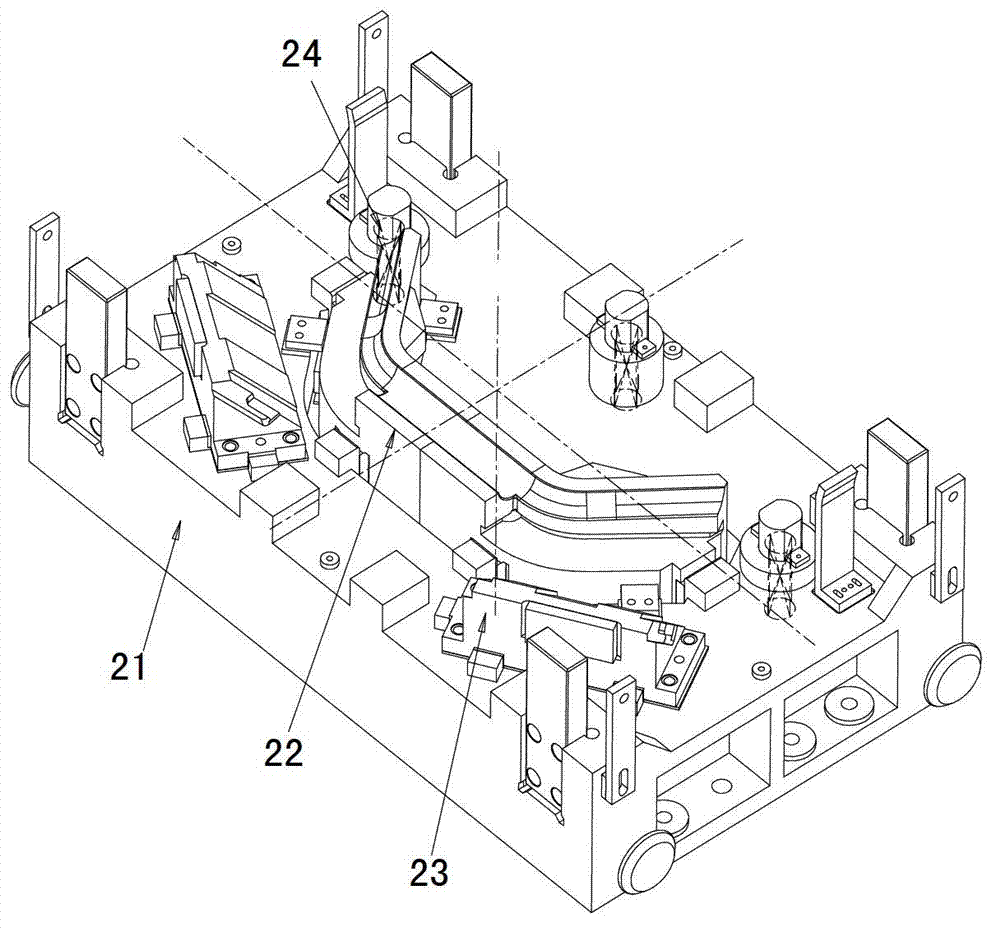

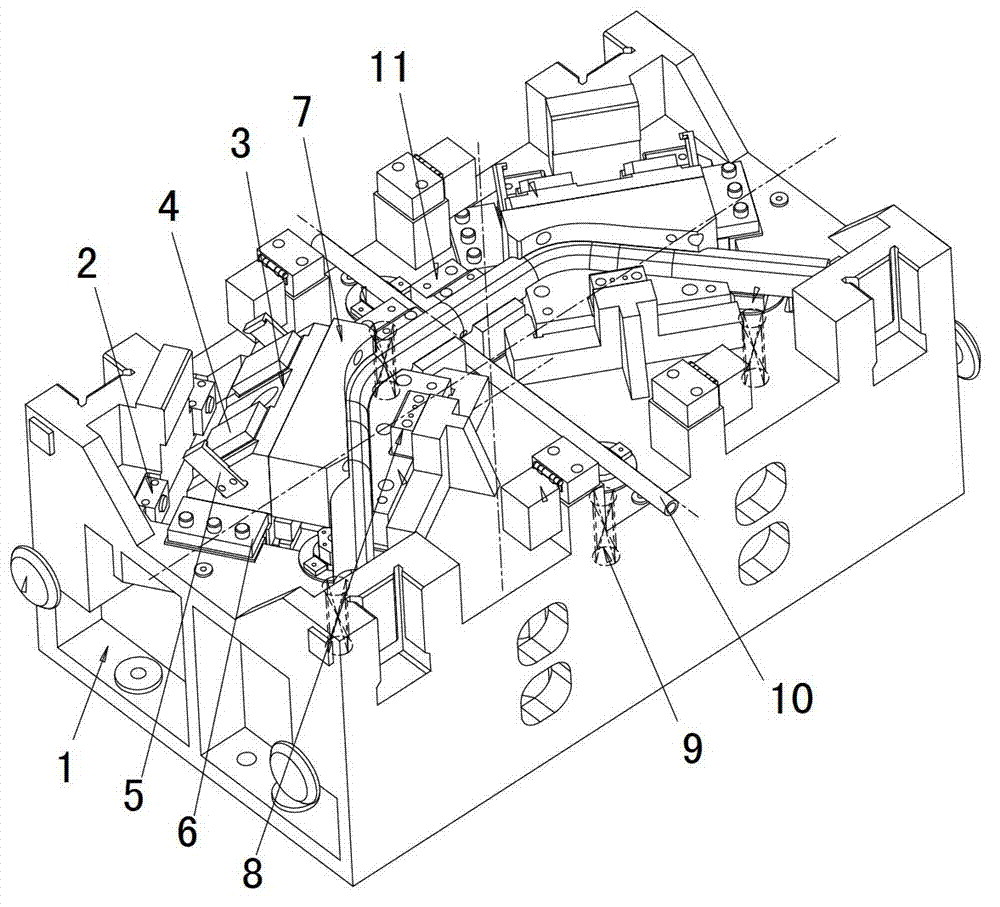

[0029] see figure 1 , figure 2 , the first set of molds used in the present invention includes an upper mold 21 and a lower mold 1 .

[0030] The upper mold 21 is provided with a pressing core 22 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com