Permanent magnet coupling sealing motor stirring device

A stirring device and permanent magnetic coupling technology, which is applied in electromechanical devices, mixers with rotating stirring devices, mixers, etc., can solve the problems of cavity sealing, no isolation device, chemical leakage, etc., and achieve practical Good performance, leakage prevention, enhanced safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

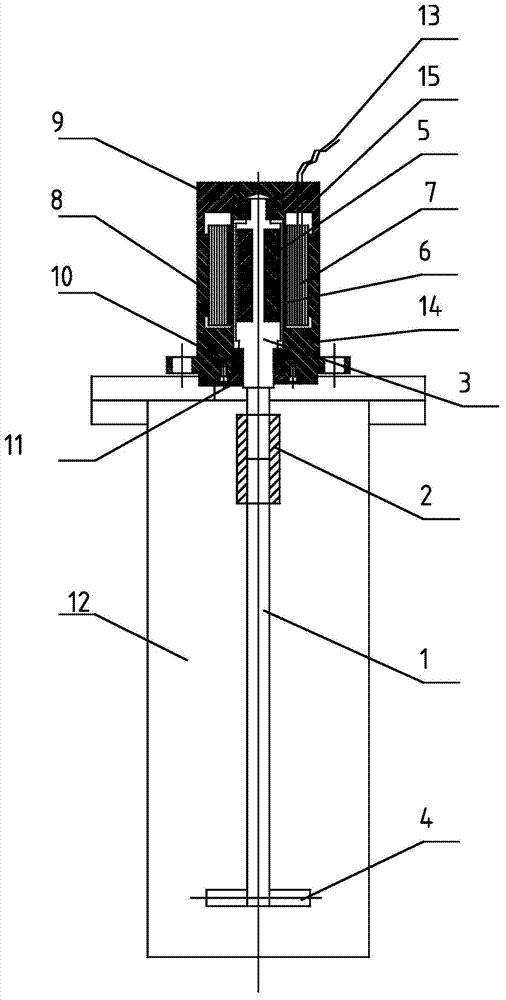

[0008] Such as figure 1 As shown, a permanent magnetic coupling sealed motor stirring device includes a stirring shaft 1, a cavity 12 and an inner rotor 3, the stirring shaft 1 is located in the cavity 12, the lower end of the stirring shaft 1 is provided with a stirrer 4, and the stirring shaft 1 The upper end is connected to the inner rotor 3 through a shaft coupling 2, and the outer periphery of the inner rotor 3 is provided with a permanent magnet 5. The upper end of the inner rotor 3 is sleeved on the upper bearing 9, and the lower end is sleeved on the lower bearing 10. It is characterized in that the outer permanent magnet 5 An isolation cover 6 is provided, a coil 7 is provided outside the isolation cover 6, a power line 13 is connected to the coil 7, a positioning sleeve 8 is provided outside the coil 7, an upper flange 15 is provided at the upper end of the positioning sleeve 8, and a bearing seat is provided at the lower end 14, and the lower bearing 10 is set on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com