Vertical continuous-cooling crystallization machine

A cooling crystallization, vertical technology, applied in the direction of solution crystallization, can solve the problems of uneven cooling and stirring of the medium, unstable product quality, uneven heat exchange area, etc., to ensure stability, simple structure, and improve crystallization yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

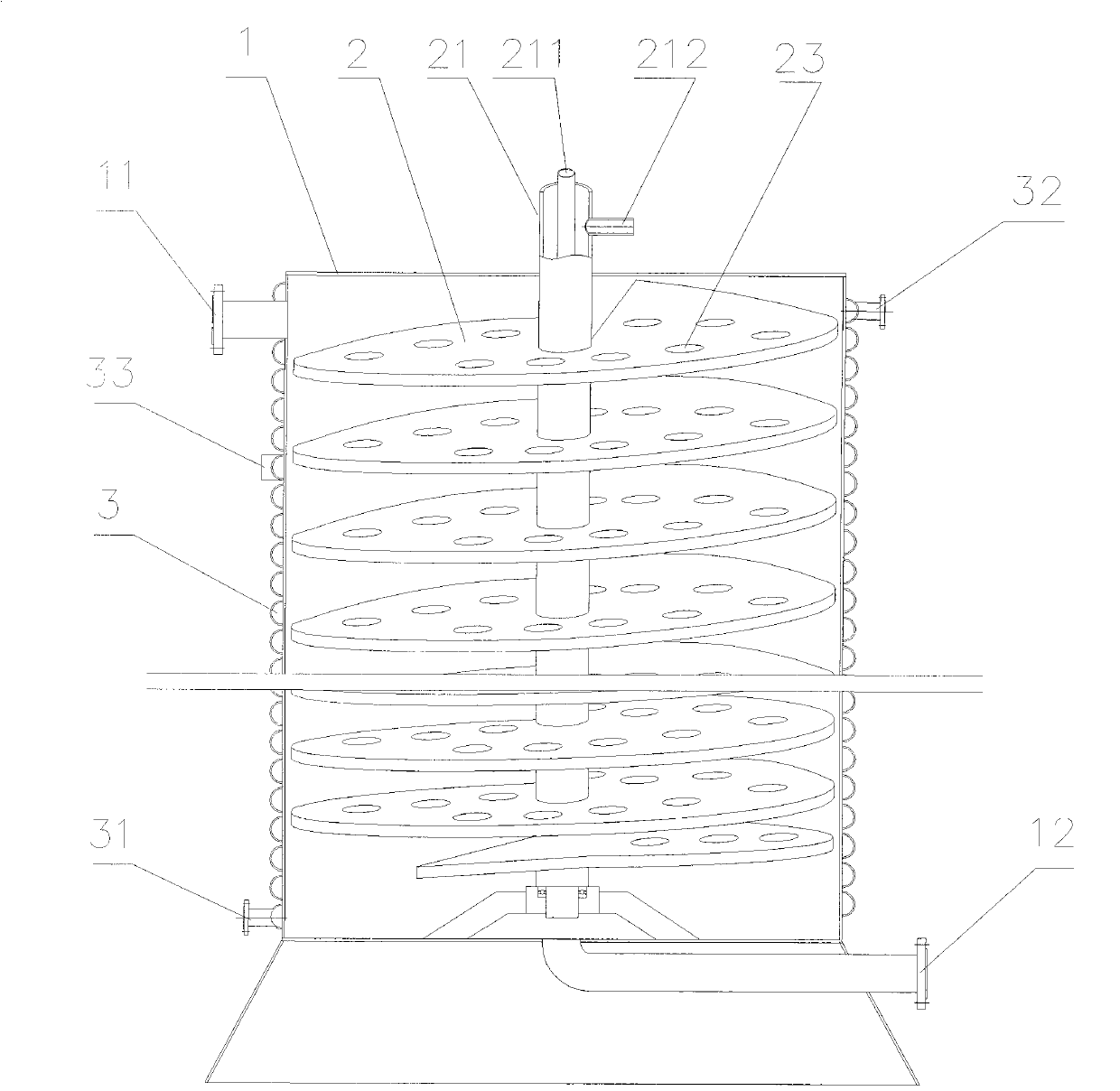

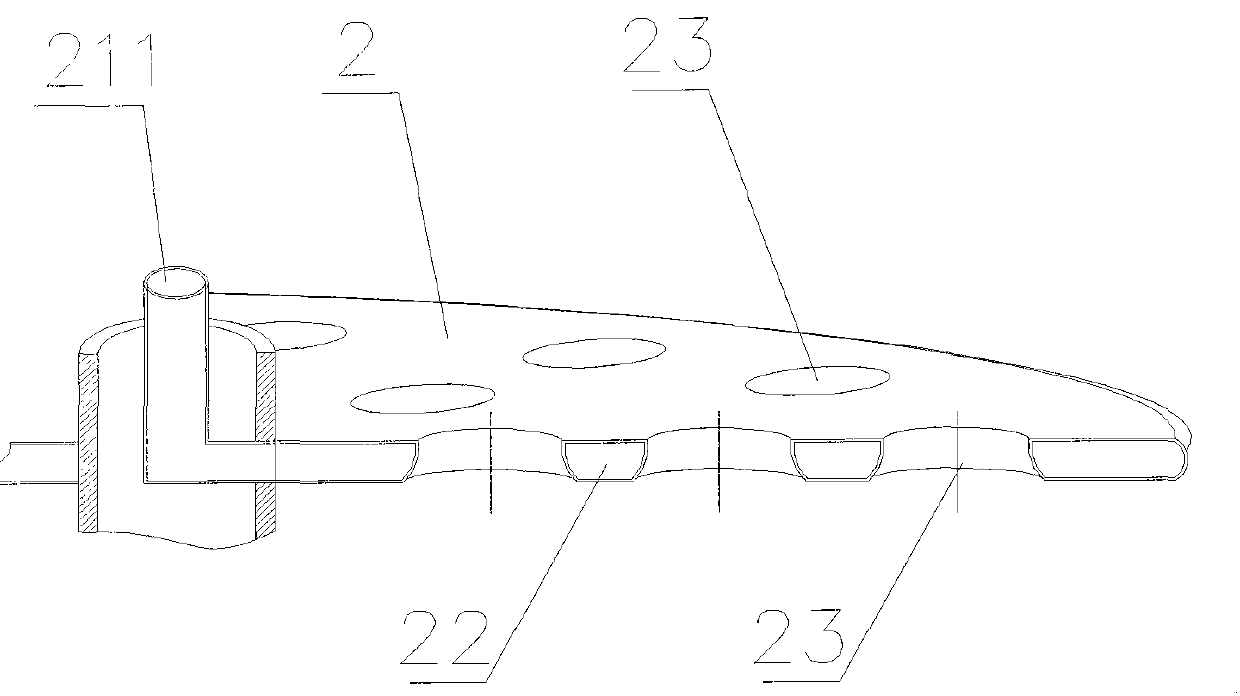

[0017] Such as figure 1 with 2 A vertical continuous cooling crystallizer shown includes an outer cylinder 1 and a helical stirring paddle 2, and the helical agitating paddle 2 is erected in the outer cylinder 1; a cooling water jacket is provided on the outer wall of the outer cylinder 1 3. The propeller impeller 2 is suspended from the top, and its shaft 21 is a sleeve-type hollow shaft structure. There is a cavity 22 inside the blade, and the upper and lower ends of the cavity 22 are respectively connected with the sleeve-type hollow shaft 21. .

[0018] The motor drives the spiral stirring paddle 2, the stirring blade water inlet 211 is connected to cooling water, and the jacket water inlet 31 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com