Preparation method of high-nutrition instant soybean milk powder

A kind of soymilk powder, high-nutrition technology, applied in the field of preparation of high-nutrition instant soymilk powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

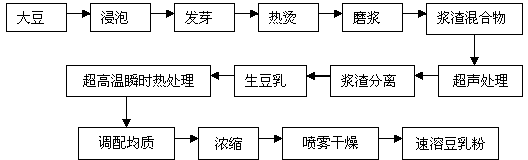

Image

Examples

preparation example Construction

[0014] A preparation method of high-nutrition instant soymilk powder, the method comprises the following steps: (1) fresh soybeans are mixed with 0.5% NaHCO 3 Soak in aqueous solution for about 10 hours, and then germinate. The germination temperature is 23-27°C, and the germination time is 72-96h. The germinated soybeans are blanched with boiling water for 5 minutes. Add weak alkaline water with a pH of 6.5-7.0 for refining, and add a reducing agent cysteine to it, the amount of cysteine added is 0.1% of the total mass of soybean water, and a slurry mixture is obtained after refining , performing ultrasonic treatment on the mixture of pulp and residue, the ultrasonic power is 400-600W, the ultrasonic temperature is 40-60°C, the ultrasonic time is 20-60min, and the pulp and residue are separated after ultrasonic treatment to obtain raw soybean milk; (2) raw soybean milk The soymilk is subjected to ultra-high temperature instantaneous heat treatment at 135°C for 30s, and th...

Embodiment 1

[0019] Fresh soybeans were washed with 0.5% NaHCO 3 Soak in aqueous solution for about 10 hours, germinate at 25°C for 84 hours, blanch the germinated soybeans with boiling water for 5 minutes, add weak alkaline water with a pH of 6.5-7.0 at a ratio of 1:7 to soybean water at 90°C for refining, and add to Add 0.1% cysteine to it, and obtain pulp and residue mixture after refining. Ultrasonic treatment is performed on the pulp and residue mixture for 40 minutes at an ultrasonic power of 500W and an ultrasonic temperature of 50°C, and then the pulp and residue are separated to obtain raw soybean milk. Perform ultra-high temperature instantaneous heat treatment at 135°C for 30s, then add 2% soybean lecithin to the heat-treated soymilk for blending and mixing, homogenize the blended soymilk under a pressure of 20MPa, and vacuum concentrate after homogenization until the soymilk is solid content of about 15%, and then spray-dried to obtain instant soybean milk powder. The Nitrog...

Embodiment 2

[0021] Fresh soybeans were washed with 0.5% NaHCO 3 Soak in aqueous solution for about 10 hours, germinate at 23°C for 84 hours, blanch the germinated soybeans with boiling water for 5 minutes, add weak alkaline water with a pH of 6.5-7.0 at a ratio of 1:7 to soybean water at 90°C for refining, and add to Add 0.1% cysteine to it, and obtain pulp and residue mixture after refining. Ultrasonic treatment is performed on the pulp and residue mixture for 50 minutes at an ultrasonic power of 450W and an ultrasonic temperature of 40°C, and then the pulp and residue are separated to obtain raw soybean milk. Perform ultra-high temperature instantaneous heat treatment at 135°C for 30s, then add 1.5% soybean lecithin to the heat-treated soymilk for blending and mixing, homogenize the blended soymilk under a pressure of 20MPa, and vacuum concentrate after homogenization until the soymilk is solid content of about 15%, and then spray-dried to obtain instant soybean milk powder. The Nitr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com