Edible mushroom factory fresh air pre-processing system

A technology for edible fungi and pretreatment, applied in the fields of application, horticulture, and botanical equipment and methods, can solve problems such as large dust, bacterial death, poor air cleanliness, etc., to reduce cleaning frequency, improve air cleanliness, The effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

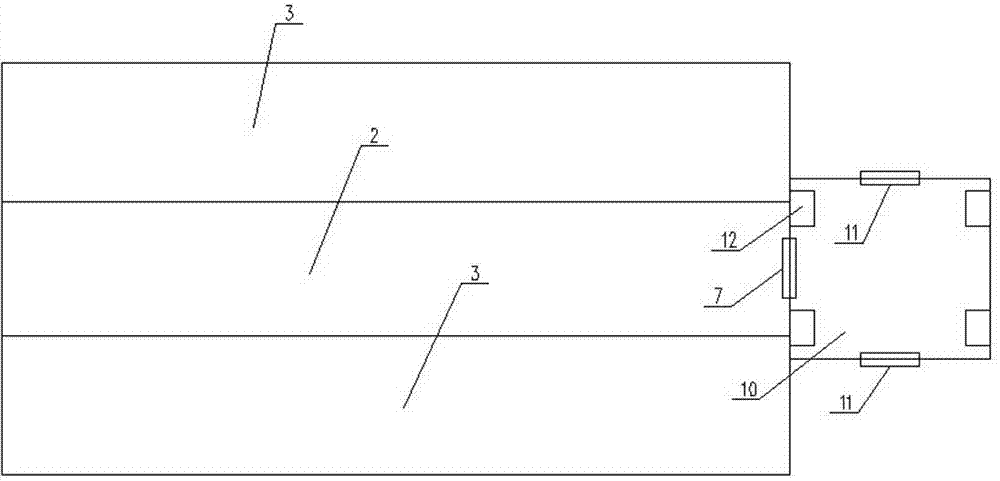

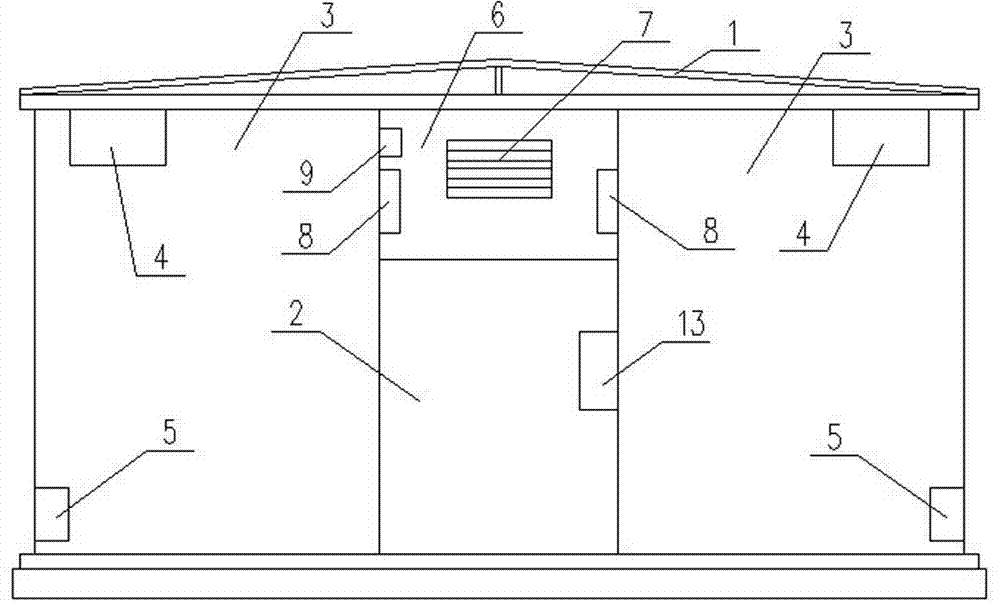

[0012] Such as figure 1 , figure 2 As shown, the fresh air pretreatment system of the edible fungus factory includes: a chamber body 1, a passage 2 arranged in the middle of the chamber body 1, a mushroom room 3 arranged in the chamber body 1 on both sides of the passage 2, and a The air-conditioning internal unit 4 and the exhaust fan 5 arranged at the lower end of the fruiting room 3 are provided with an airtight chamber 6 at the upper end of the passage 2, an air inlet is arranged at one side of the airtight chamber 6, and an air inlet is provided at the air inlet. A high-efficiency filter screen 7 is provided with a fresh air blower 8 on both sides of the airtight chamber 6, a humidifier 9 is arranged in the airtight chamber 6, and an air preheater is arranged on the chamber body 1 outside the air inlet. Process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com