A wind-water hybrid cooling high-speed permanent magnet motor with hybrid protection for the rotor

A hybrid cooling, permanent magnet motor technology, used in cooling/ventilation devices, electromechanical devices, electrical components, etc., can solve the loss density of damaged high-power and high-density motors, affecting motor reliability and operating life, and insufficient permanent magnet strength, etc. problems, to achieve the effect of reducing the temperature rise distribution of the rotor, improving the electromagnetic characteristics, and reducing the edge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

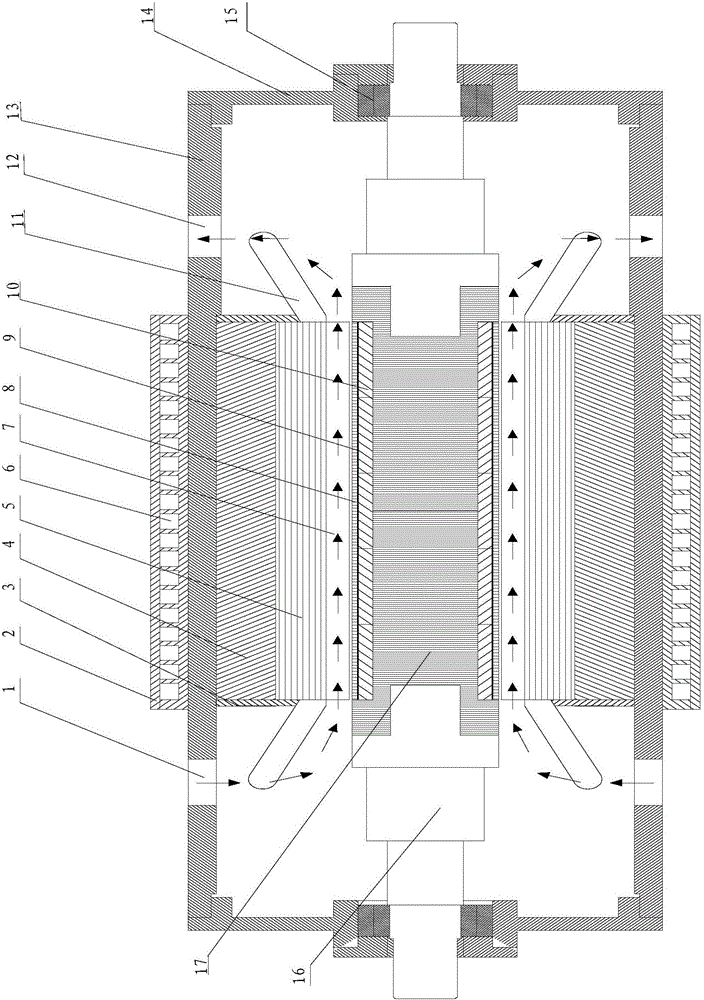

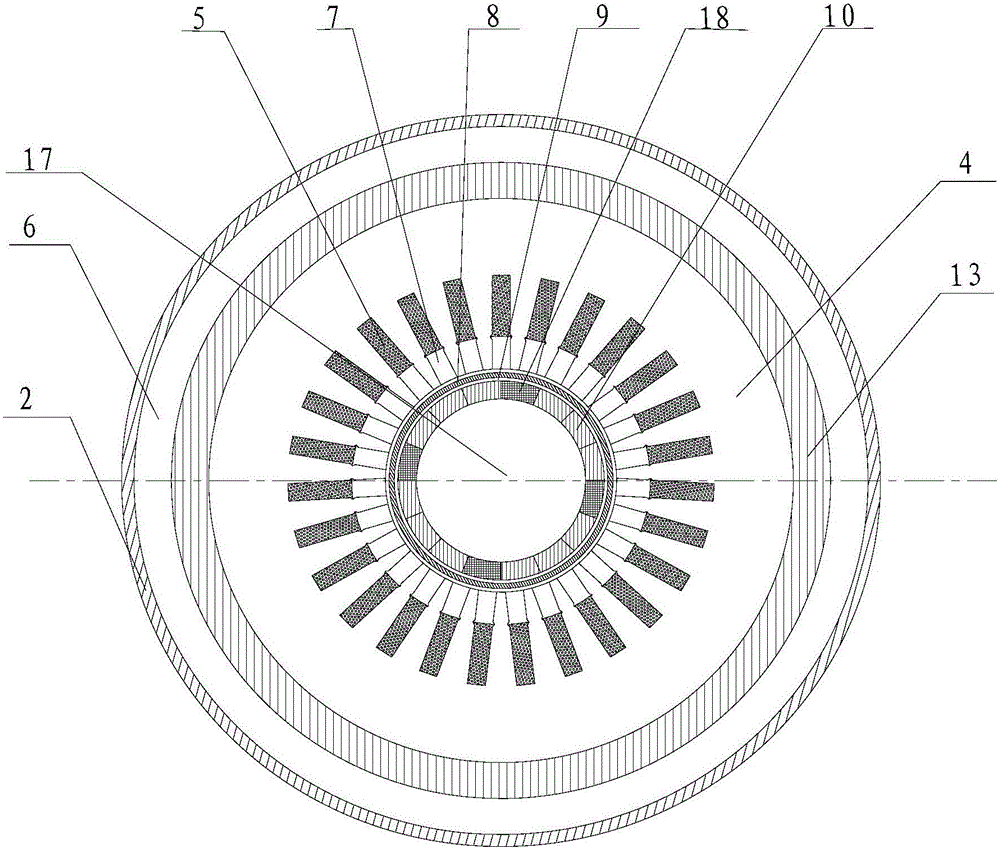

[0023] detailed description: The present invention is specifically described below in conjunction with accompanying drawing:

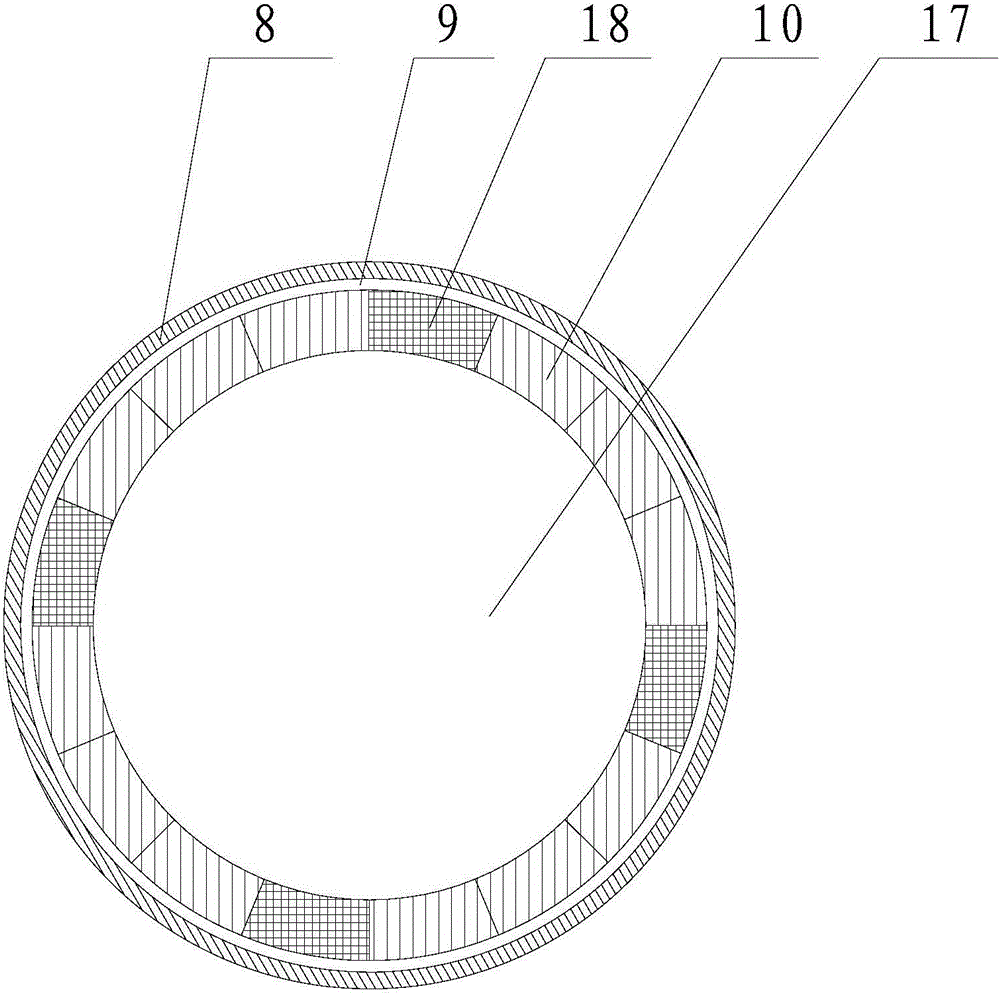

[0024] The invention is a permanent magnet synchronous motor, the stator slot adopts rectangular slots, the number of slots per pole and each phase is fractional slots, the winding adopts double-layer short-distance windings, and the heat dissipation system adopts a combined cooling method of air cooling and water cooling, and the air cooling system Set between the stator and rotor, the cold air flows in from the air inlet on one side of the casing, passes through the end of the winding, flows to the axial inner air duct, passes through the end of the winding at the other end, and flows out from the air outlet on the other end of the casing. Water cooling system It is located outside the motor casing and adopts a circumferential spiral pipe. The motor rotor adopts surface-mounted permanent magnets. The permanent magnet hybrid protective cover is comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com