Elevator built-in safety gear

A safety gear and elevator technology, applied in lifts, transportation and packaging, etc., can solve the problems of difficult installation and complex safety gear structure, and achieve the effect of reducing accident risk and small size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

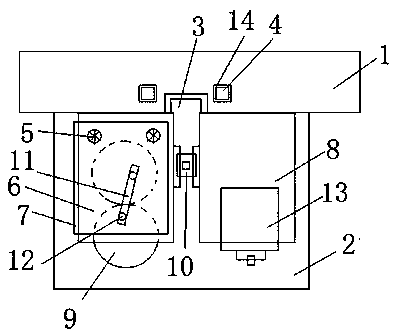

[0011] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0012] An elevator built-in safety gear, which includes a fixed plate 1, a casing 2, a groove 3, a fixed hole 4, a fixed bolt 5, a panel 6, a gear box 7, an induction box 8, a roller 9, a locking clip 10, and a chute 11. Connecting strip 12, speed sensing module 13, fixed plate 1 is installed above the casing 2, a small groove 3 is opened on the fixed plate 1, fixing holes 4 are opened on both sides of the small groove, and the gear box 7 is installed on the fixed Below the plate 1, two rollers 9 are installed in the gear box 7, and the rollers 9 are connected by connecting bars 12. The outer surface of the gear box 7 is equipped with a panel 6, and the panel 6 and the gear box 7 are fixed by fixing bolts 5. The panel There is a chute 11 on the 6, and the connecting bar 12 is embedded in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com