Multi-hole nanometer copper oxide composite material, method for preparing same, supercapacitor electrodes and supercapacitor

A nano-copper oxide and composite material technology, which is applied in the field of nano-materials, can solve the problems of difficult preparation of supercapacitor electrodes, difficult to meet application requirements, poor conductivity, etc., and achieve long charge-discharge cycle life, good crystal shape, and small attenuation effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

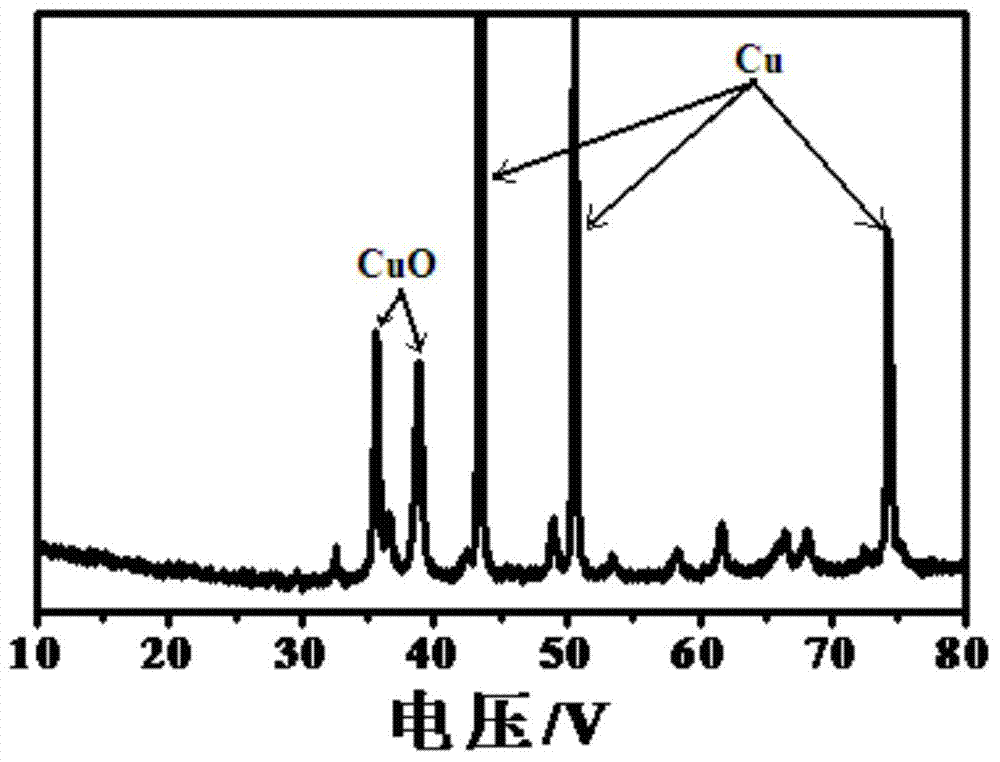

[0034] A porous nano-copper oxide composite material is composed of porous nano-copper oxide grown on a copper substrate, and the porous nano-copper oxide is tiled on the copper substrate in a three-dimensional network.

[0035] A preparation method of a porous nano-copper oxide composite material, the steps comprising:

[0036] a. Put the copper sheet into acetone, ethanol, dilute hydrochloric acid, and water in sequence, and perform ultrasonic cleaning; the ultrasonic cleaning time in acetone, ethanol, dilute hydrochloric acid, and water is 12, 15, 12, and 10 min respectively, and the concentration of the dilute hydrochloric acid is 3mol / L;

[0037] b. Add 20mL of 0.005mol / L potassium permanganate solution into the reaction kettle, and then 2 , the copper piece with a length of 4cm is immersed in potassium permanganate solution, tighten the lid of the reaction kettle, react at 100°C for 4 hours, cool to room temperature, take out the copper piece after reaction, clean it w...

Embodiment 2

[0044] A porous nano-copper oxide composite material is composed of porous nano-copper oxide grown on a copper substrate, and the porous nano-copper oxide is tiled on the copper substrate in a three-dimensional network.

[0045] A preparation method of a porous nano-copper oxide composite material, the steps comprising:

[0046] a. Put the copper sheet into acetone, ethanol, dilute hydrochloric acid, and water successively, and perform ultrasonic cleaning; the ultrasonic cleaning time in acetone, ethanol, dilute hydrochloric acid, and water is 15, 10, 10, and 15 min respectively, and the concentration of the dilute hydrochloric acid is 5 mol / L;

[0047] b. Add 20mL of 0.001mol / L potassium permanganate solution into the reaction kettle, and then 2, immerse the copper piece with a length of 4cm in the potassium permanganate solution, tighten the lid of the reaction kettle, react at 150°C for 8 hours, cool to room temperature, take out the copper piece after reaction, clean it ...

Embodiment 3

[0051] A porous copper oxide nanocomposite material consists of porous copper oxide nanomaterials grown on a copper substrate.

[0052] A method for preparing a porous copper oxide nanocomposite material, the steps comprising:

[0053] a. Put the copper sheet into acetone, ethanol, dilute hydrochloric acid, and water in turn, and perform ultrasonic cleaning; the ultrasonic cleaning time in acetone, ethanol, dilute hydrochloric acid, and water is 15, 10, 15, and 15 min respectively, and the concentration of the dilute hydrochloric acid is 4mol / L;

[0054] b. Add 20mL of 0.01mol / L potassium permanganate solution into the reaction kettle, and then make the 2 , immerse the copper piece with a length of 4cm in the potassium permanganate solution, tighten the lid of the reaction kettle, react at 50°C for 2 hours, cool to room temperature, take out the copper piece after reaction, clean it with distilled water and absolute ethanol, and dry it at room temperature. Porous copper oxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com