Spectroscopy technique using merged spectral data

A spectrum and spectrum measurement technology, applied in the field of spectroscopic devices, can solve problems such as weak spectral peaks, difficult detection, low brightness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] figure 1 A charged particle microscope 400 is shown, which in this case is a SEM. The microscope 400 includes a particle optics column 402 that generates a charged particle beam 404 (in this case an electron beam). The particle optics column 402 is mounted on the vacuum chamber 406, which includes a sample holder / stage 408 for holding the sample 410. A vacuum pump (not shown) is used to evacuate the vacuum chamber 406. With the help of the voltage source 422, the sample holder 408 or at least the sample 410 can be biased (floated) to a potential relative to ground.

[0069] The particle optics column 402 includes an electron source 412, compound lens systems 414 and 416 for focusing the electron beam 404 on the sample 410, and a deflection unit 418. Regarding the detector, the device is equipped with:

[0070] -A first detector 420 for detecting the flux of laser sub-radiation emitted from the sample 410 in response to the irradiation by the beam 404. In this example, th...

Embodiment 2

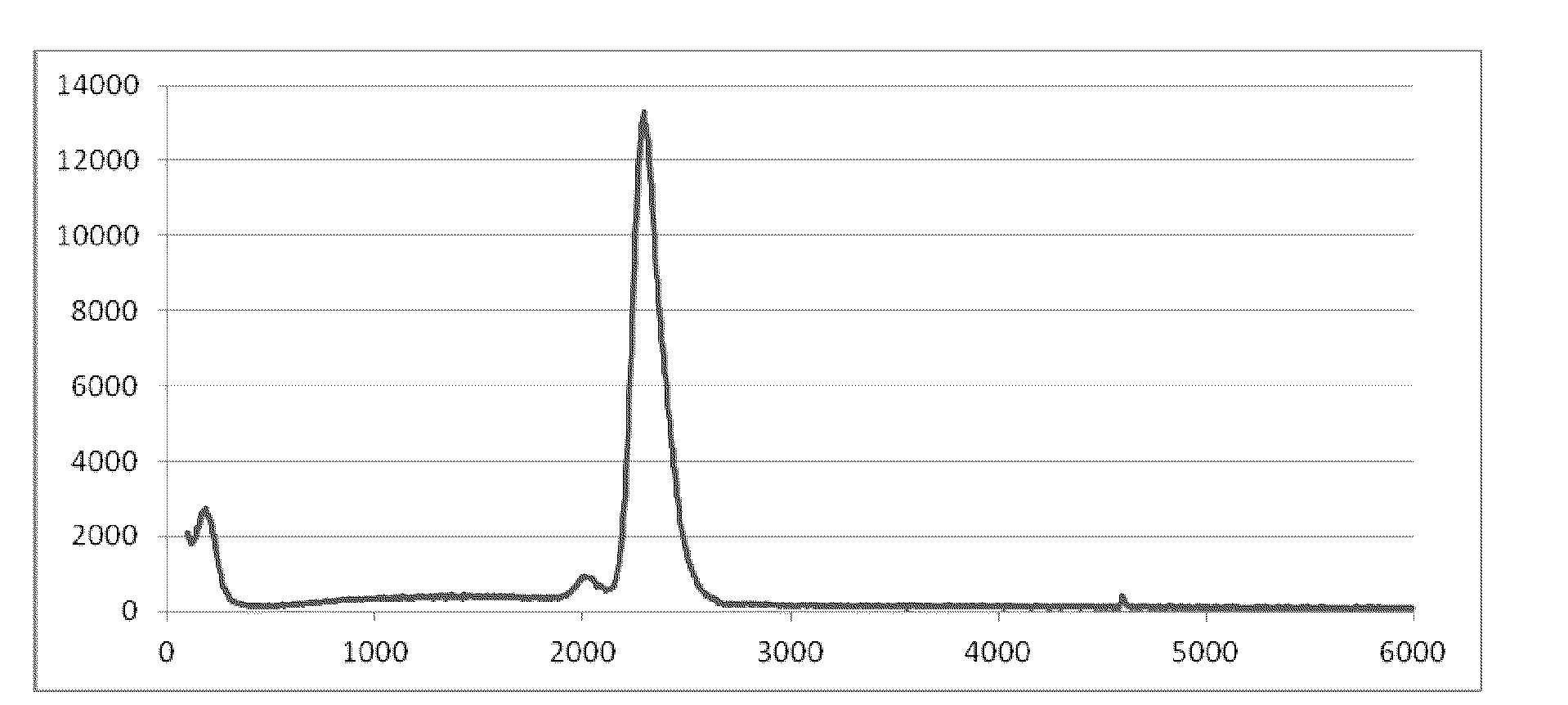

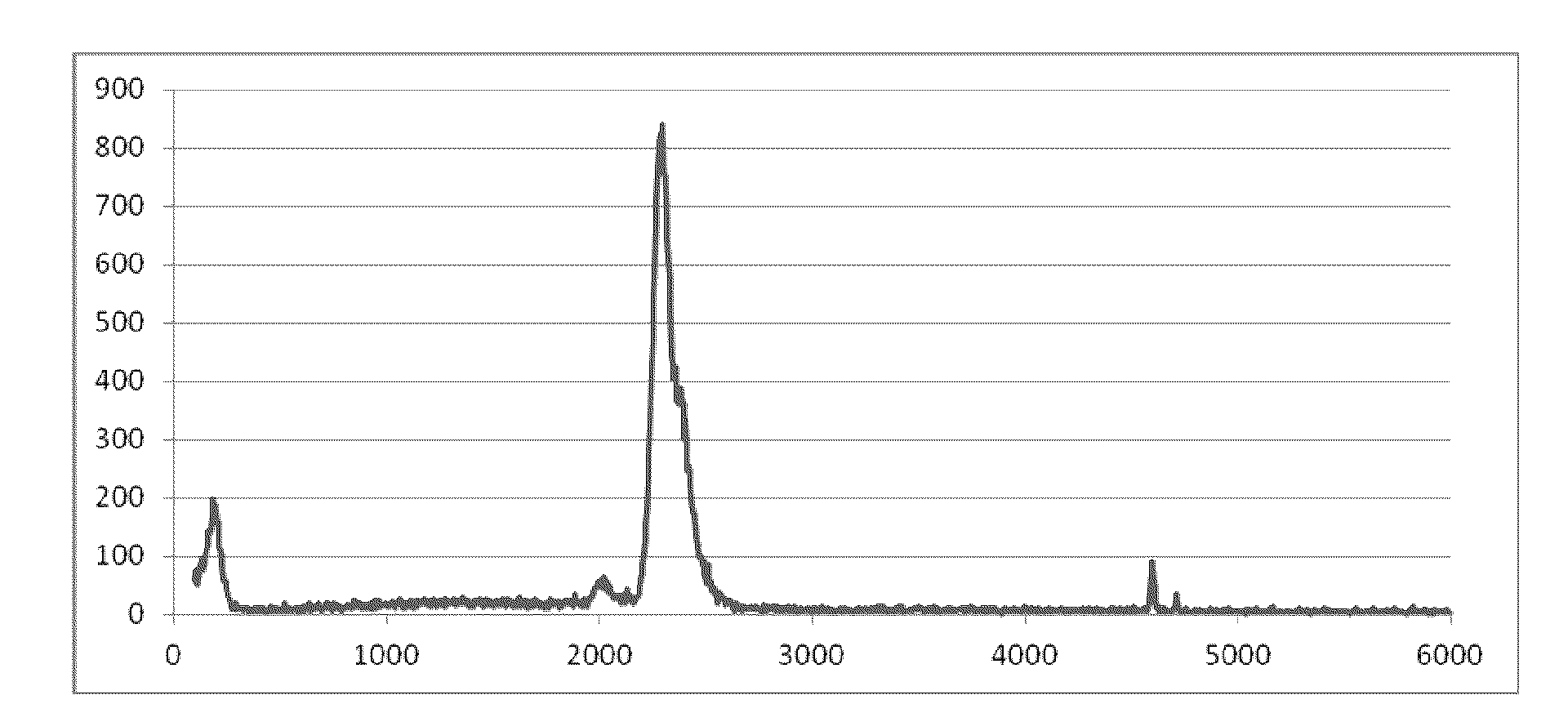

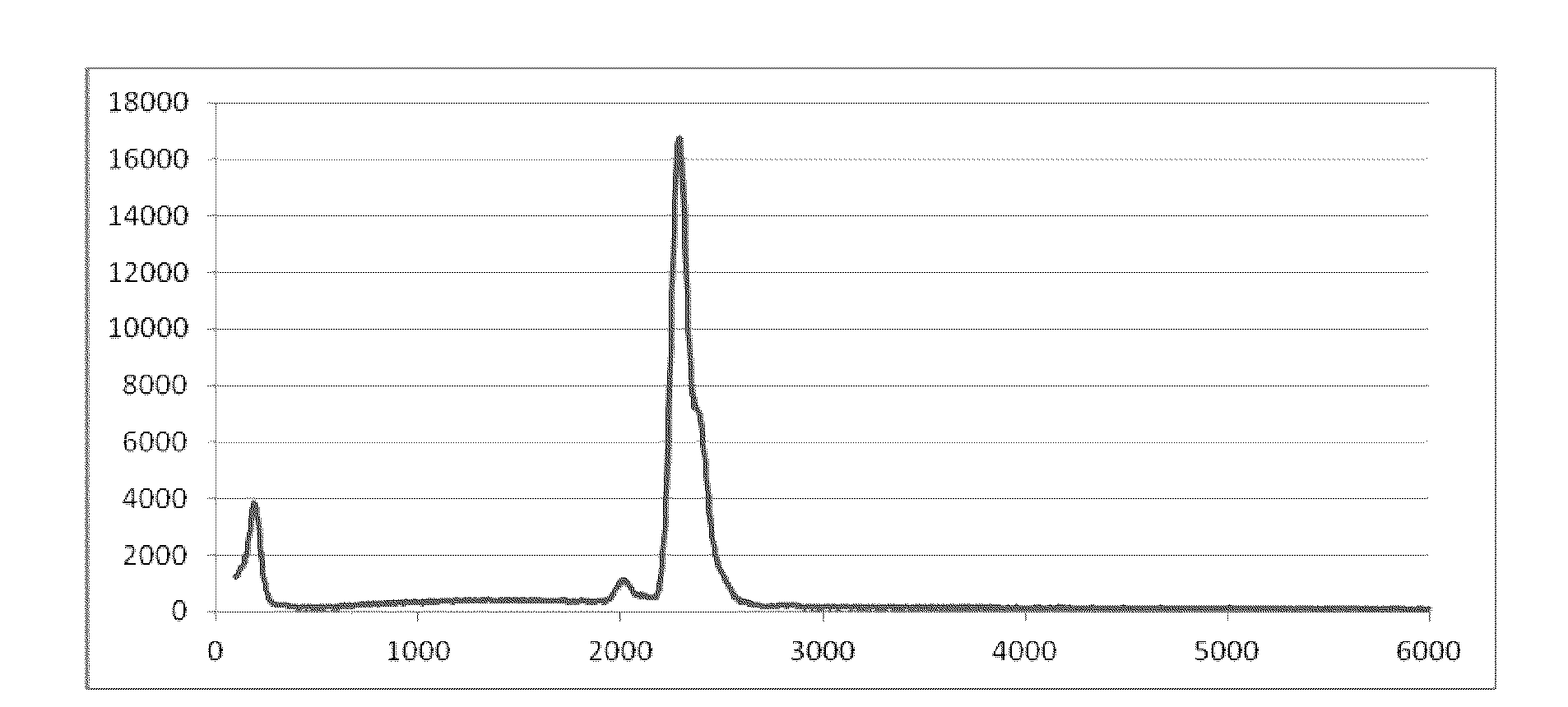

[0082] figure 2 The EDX / EDS spectra accumulated from metallurgical samples are shown. The spectrum is the measured intensity along the ordinate (proportional to the photon count of each channel) versus the photon energy in keV along the abscissa (determined by the channel into which the photon is classified by the processing circuit associated with the detector) Graph. The spectrum shows multiple different peaks superimposed on the lower background.

[0083] The location and relative height of a particular set of these peaks are characteristics of the element that generated them. For example, in the depicted spectrum, vanadium (V) generates triad (distinguishable) peaks at energies of approximately 0.5, 4.9, and 5.4 keV. On the other hand, chromium (Cr) is responsible for the peaks at approximately 0.5, 5.4, and 5.95 keV (two of which clearly correspond to the corresponding peaks of vanadium in the energy resolution adopted along the horizontal axis).

[0084] Now move on to Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com