Oil baffle plate and compressor applying oil baffle plate

An oil baffle, oil and gas technology, which is applied to the parts of pumping devices for elastic fluids, mechanical equipment, machines/engines, etc., can solve the problems of large amount of refrigeration oil and adverse effects on the performance of air conditioning systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

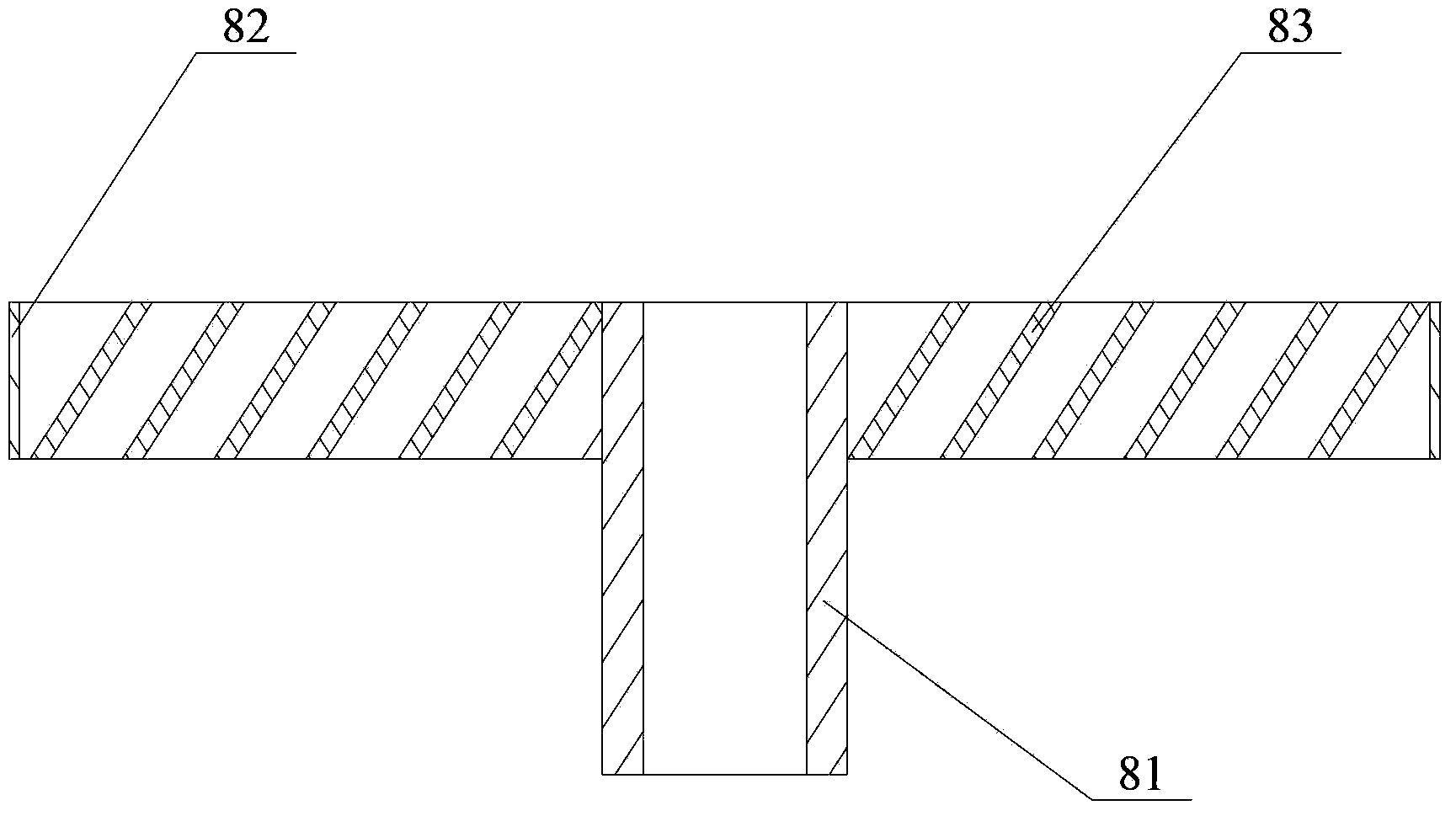

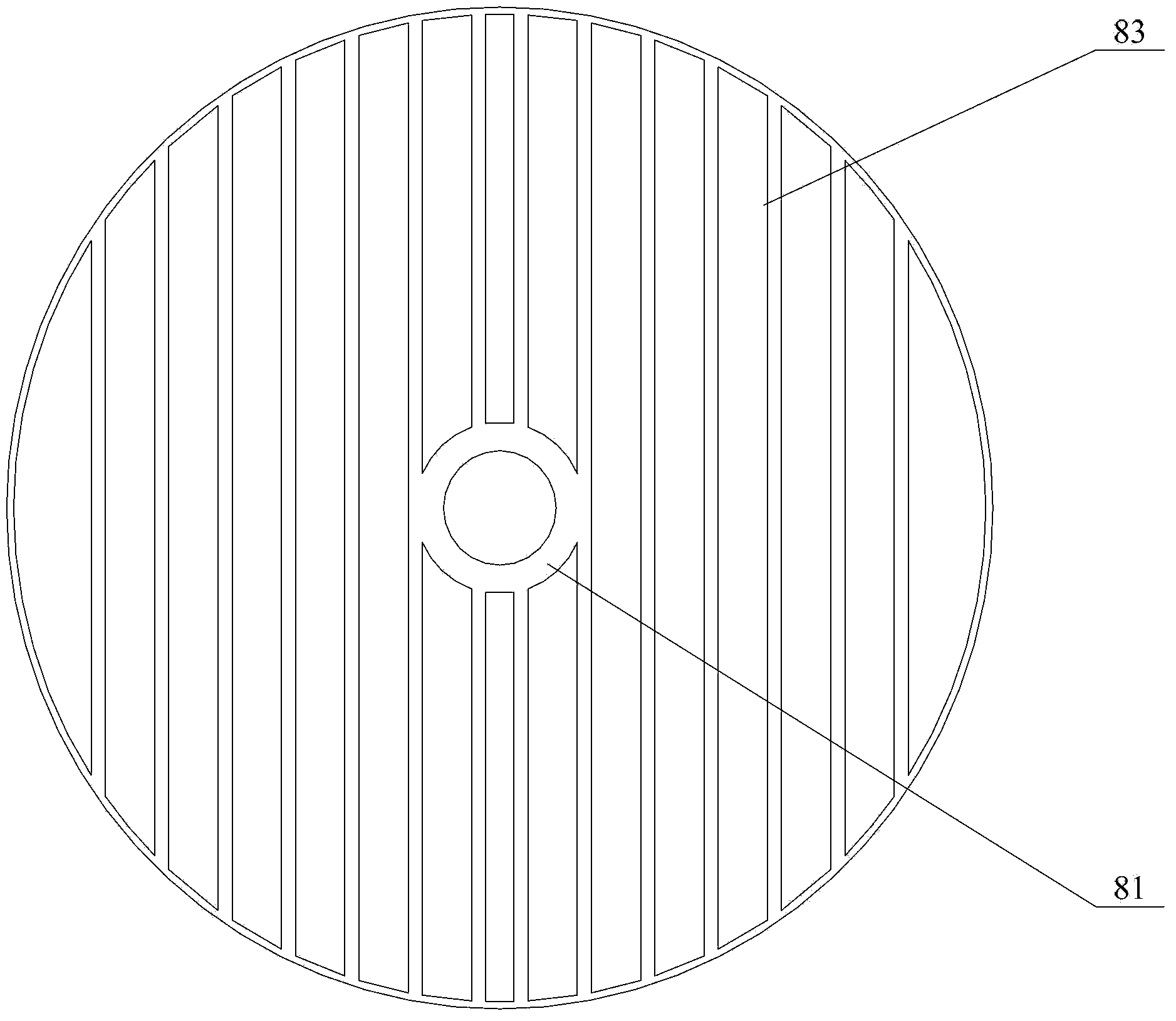

[0029] The core of the present invention is to provide an oil baffle, which can reduce the refrigerating oil flowing out from the casing of the compressor. Another core of the present invention is to provide a compressor with the above-mentioned oil baffle.

[0030] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

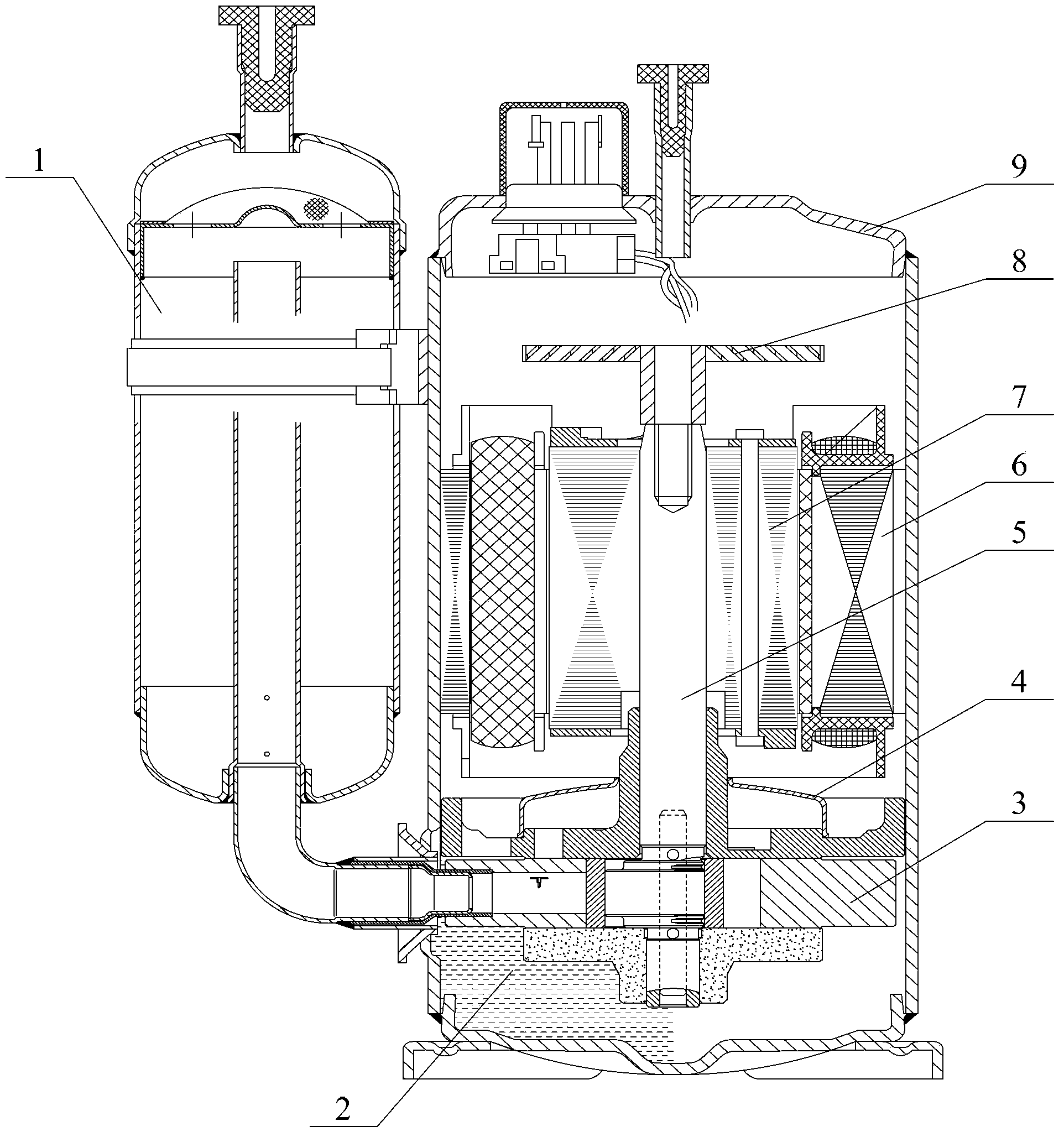

[0031] like figure 1 As shown, after the stator 6 and rotor 7 of the compressor are energized, they form a motor that drives the crankshaft 5 to rotate. Driven by the stator 6 and rotor 7, the crankshaft 5 can drive the rolling rotor connected to it to move in the cylinder 3, so that the low-pressure gas It is sucked into the compressor from the gas cylinder 1, and at the same time, the rotation of the rolling rotor compresses the low-pressure gas into high-pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com