Fan aerodynamic layout structure and method of a turbofan engine

A turbofan engine and aerodynamic layout technology, applied in the direction of engine components, machines/engines, liquid fuel engines, etc., can solve the problems of reduced fan reaction force, increased design difficulty, increased loss, etc., to achieve reduced diameter and weight, The effect of improving the flow capacity and increasing the bypass ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the examples, the following examples are explanations of the present invention and the present invention is not limited to the following examples.

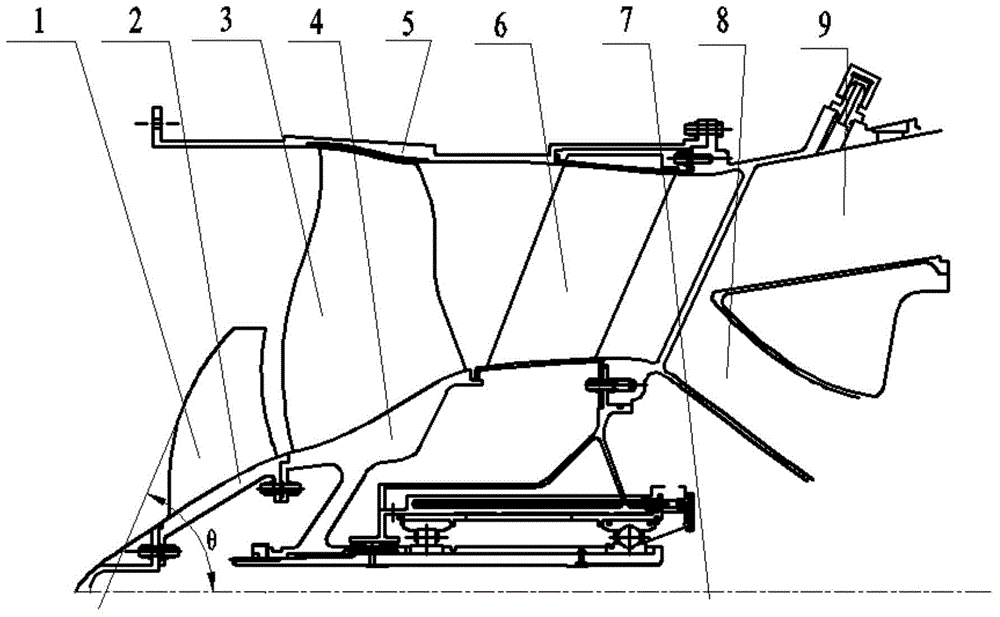

[0019] Such as figure 1 As shown, the present embodiment is used in the fan aerodynamic layout structure of a high-performance aviation turbofan engine, including fan rotor blades 3, fan rotor discs 4, fan stator blades 6 and fan outer casing 5, in order to improve the fan near the hub Flow rate and supercharging ratio, a non-full-blade high-pressure rotor composed of non-full-blade high-rotor blade 1 and non-full-blade high-rotor disc 2 is designed at the inlet of the fan rotor. The number of blades is the same, and the fan rotor rotates in the same direction as the fan rotating shaft 7 at the same speed. Further, the radial height of the non-full-blade high-pressure rotor blade is 15% to 30% of the height of the fan rotor blade, and the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com