Texturing machine provided with improved oiling machine

A texturing machine and oil tank technology, applied in textiles and papermaking, etc., can solve the problems of inconsistent quality of finished silk and inability to oil the composite silk, so as to achieve uniform oiling and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

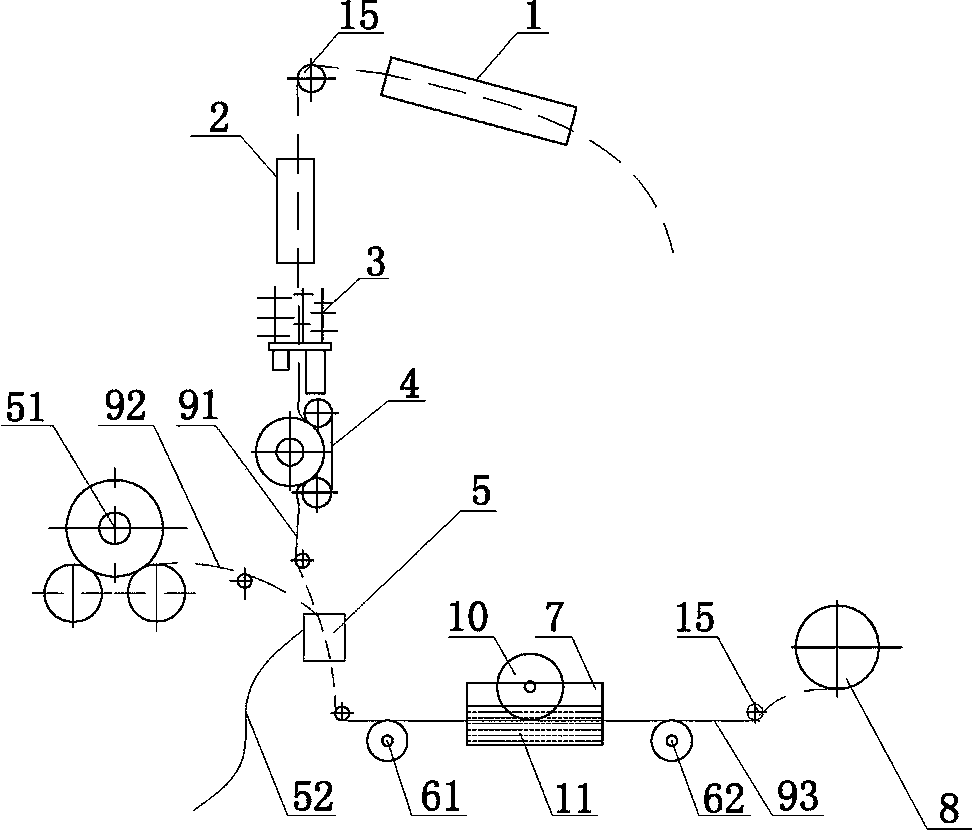

[0011] Please refer to the attached figure 1 As shown, the present invention is a texturing machine with an improved oiling mechanism, which is used to compound polyester yarn 91 and spandex 92 to form composite yarn 93, which consists of heating rail 1, cooling rail 2, false twisting rails arranged in sequence It is composed of device 3, roller 4, compound air nozzle 5, front wire feeding roller 61, oiling tank 7, rear wire feeding roller 62 and winding device 8, etc.

[0012] Wherein, the heating rail 1 is used for heating and deforming the polyester filament 91 . The cooling rails 2 are used for cooling the heated and deformed polyester filaments 9 . The false twister 3 makes the polyester yarn 91 produce false twist. The roller 4 is used to feed the polyester yarn 91 into the composite air nozzle 5 . A turning wheel 15 is provided between the heating rail 1 and the cooling rail 2 , between the roller 4 and the front wire feeding roller 61 , and between the rear wire fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com