Method for synchronously preparing high-stability rice bran oil and rice bran protein

A technology of rice bran protein and rice bran oil, which is applied in the field of vegetable oil and protein extraction and processing, and can solve the problems of difficult extraction effect, denaturation of rice bran protein, and low oil extraction rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

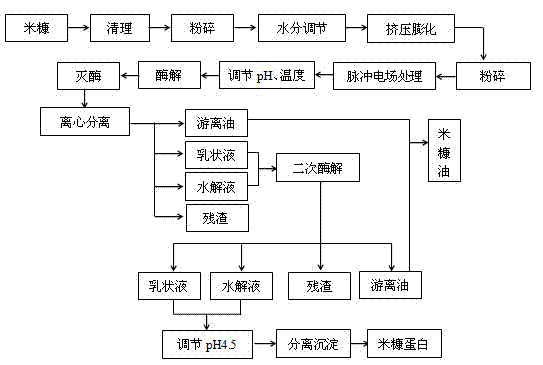

Image

Examples

Embodiment 1

[0024] The rice bran is crushed and passed through a 60-mesh sieve, and then extruded and extruded to obtain an extruded product. The die hole diameter of the extruder extruder is 18mm, the rotation speed of the extrusion screw is 120r / min, the temperature of the sleeve is 150°C, and the moisture content of the material is 18.5%; (2) The puffed product is pulverized and mixed with water to obtain a mixed solution. The weight ratio of the puffed product to water is 1:7. The mixed solution is subjected to pulse electric field treatment. The pulse time is 300μs and the flow rate is 60mL / min, pulse intensity 30kV / cm, pulse frequency 400Hz; (3) Add Protex-6L alkaline protease to the mixed solution after pulse electric field treatment for enzymolysis to obtain enzymolysis solution, the enzymolysis temperature is 56°C, enzymolysis The time is 1.98 hours, the amount of enzyme added is 2% of the weight of the material, the pH of the enzymolysis is 9.5, the enzymolysis solution is deact...

Embodiment 2

[0027]The rice bran is crushed and passed through a 60-mesh sieve, and extruded and extruded to obtain an extruded product. The die hole diameter of the extruded extruder is 15 mm, the rotational speed of the extruding screw is 120 r / min, the temperature of the sleeve is 140 ° C, and the moisture content of the material is 18.5%; (2) The puffed product is pulverized and mixed with water to obtain a mixed solution. The weight ratio of the puffed product to water is 1:7. The mixed solution is subjected to pulse electric field treatment. The pulse time is 350μs and the flow rate is 60mL / min, pulse intensity 30kV / cm, pulse frequency 400Hz; (3) Add Protex-6L alkaline protease to the mixed solution after pulse electric field treatment for enzymolysis to obtain enzymolysis solution, the enzymolysis temperature is 56°C, enzymolysis The time is 1.98h, the amount of enzyme added is 2% of the weight of the material, the pH of the enzymolysis is 9, the enzymolysis solution is deactivated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com