A kind of synthetic method of dimer acid glycidyl ester

A technology of glycidyl ester and synthesis method is applied in the field of synthesizing dimer acid glycidyl ester, can solve the problems to be further improved and the like, and achieve the effects of stable product index, low viscosity and high epoxy value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

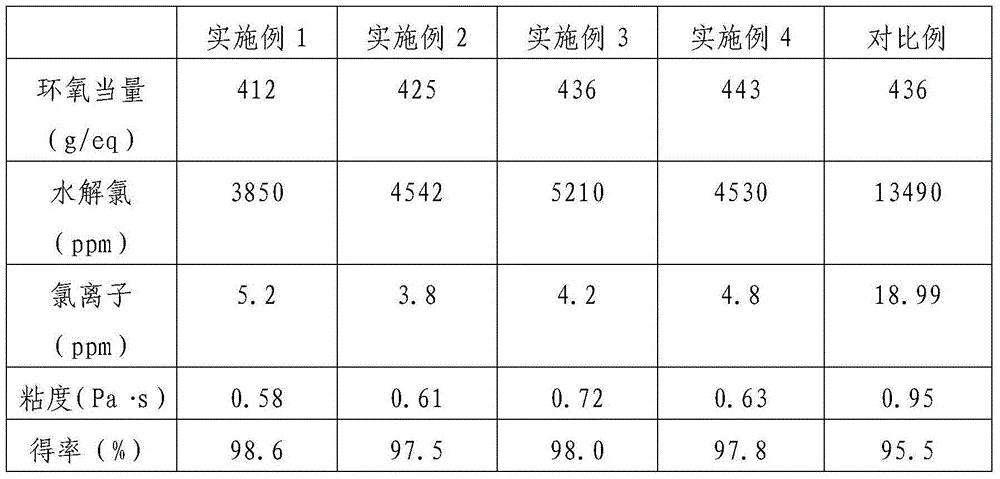

Examples

Embodiment 1

[0019] Add 178g of dimer acid, 569g of epichlorohydrin and 2.5g of NaOH into a 1L reaction flask, stir, raise the temperature to 90°C, and maintain the reaction temperature at 90°C for 2h to obtain an intermediate with a chlorohydrin ester structure, and continue to add 2.67g of NaOH to the system. g benzyltrimethylammonium chloride, then raise the vacuum degree of the system to 140torr, control the temperature at 65°C, add 53.36g of 50% NaOH solution dropwise at a constant speed within 3 hours, and continue stirring at this temperature after the dropwise addition is completed React for 1 hour. After the reaction was completed, break the vacuum, add 200g of 80°C deionized water, stir for 5 minutes and let stand, separate liquid to remove salt, remove excess unreacted epichlorohydrin, and filter to obtain 202g of dimer acid glycidyl ester. Epoxy equivalent 412g / eq, hydrolyzed chlorine 3850ppm.

Embodiment 2

[0021] Add 178g of dimer acid, 569g of epichlorohydrin, and 5g of NaOH into a 1L reaction bottle, stir, raise the temperature to 85°C, and maintain the reaction temperature at 85°C for 4h to obtain an intermediate with a chlorohydrin ester structure, and continue to add 5.34g of benzyl to the system Triethylammonium chloride, then raise the vacuum degree of the system to 140torr, control the temperature at 65°C, add 49.48g of 50% NaOH solution dropwise at a constant speed within 2 hours, and continue stirring at this temperature for 1 Hour. After the reaction, break the vacuum, add 200g of 80°C deionized water, stir for 5 minutes and let it stand, then separate the liquid to remove the salt and excess unreacted epichlorohydrin, and filter to obtain 196g of dimer acid glycidyl ester. Epoxy equivalent 425g / eq, hydrolyzed chlorine 4542ppm.

Embodiment 3

[0023] Add 178g of dimer acid, 569g of epichlorohydrin, and 5g of KOH into a 1L reaction bottle, stir, raise the temperature to 90°C, and maintain the reaction temperature at 90°C for 2h to obtain an intermediate with a chlorohydrin ester structure, and continue to add 2.67g of tetrachloride to the system. Methyl ammonium bromide, then the vacuum degree of the system was raised to 130torr, the temperature was controlled at 60°C, and 48.13g of 50% NaOH solution was added dropwise at a uniform speed within 2 hours. After the dropwise addition, the reaction was continued at this temperature for 1 hour. After the reaction is complete, break the vacuum, add 200g of 80°C deionized water, stir for 5 minutes and let stand, separate liquid to remove salt, remove excess unreacted epichlorohydrin, and filter to obtain 198g of dimer acid glycidyl ester. The epoxy equivalent is 436g / eq, and the hydrolyzed chlorine is 5210ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com