Medical high-gloss waterproof digital ink-jet printed color film and preparation method

A color film and digital inkjet technology, applied in the field of medical supplies, can solve the problems of short image storage time, long film output cycle, easy fading, etc., and achieve long image storage time, easy to carry and store, and long image storage time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

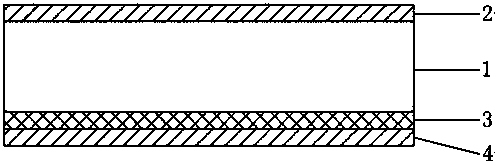

[0030] Such as figure 1As shown, the medical high-gloss waterproof digital inkjet printing color film includes a substrate 1 and a coating on the substrate 1, the substrate 1 is a high-gloss PET sheet, and the coating includes a high-gloss waterproof ink-absorbing layer 2 , antistatic layer 4 and adhesive layer 3; one side of substrate 1 is coated with high-gloss waterproof ink-absorbing layer 2, the other side of substrate 1 is coated with adhesive layer 3, and the other side of adhesive layer 3 is coated with antistatic layer 4.

[0031] The high-gloss waterproof ink-absorbing layer includes the following components: 10kg of SPL-100 aluminum powder from Guangzhou Huigu Chemical Co., Ltd., 1.5kg of adhesive PVA235, 0.5kg of dispersant, 4kg of color-fixing agent, and 0.5kg of water-based whitening agent. kg, 0.2kg of polyether surfactant SN-126, 3.2kg of pH regulator, 80kg of deionized water, 0.05kg of boric acid, and 0.05kg of n-butanol.

[0032] A preparation method for me...

Embodiment 2

[0042] Such as figure 1 As shown, the medical high-gloss waterproof digital inkjet printing color film includes a substrate 1 and a coating on the substrate 1, the substrate 1 is a high-gloss PET sheet, and the coating includes a high-gloss waterproof ink-absorbing layer 2 , antistatic layer 4 and adhesive layer 3; one side of substrate 1 is coated with high-gloss waterproof ink-absorbing layer 2, the other side of substrate 1 is coated with adhesive layer 3, and the other side of adhesive layer 3 is coated with antistatic layer 4.

[0043] The high-gloss waterproof ink-absorbing layer includes the following components: 15kg of SPL-100 aluminum powder from Guangzhou Huigu Chemical Co., Ltd., 2kg of adhesive PVA235, 0.5kg of dispersant, 3kg of color-fixing agent, and 0.5kg of water-based brightener , 0.4kg of polyether surfactant SN-126, 3.5kg of pH regulator, 75kg of deionized water, 0.05kg of boric acid, and 0.05kg of n-butanol.

[0044] A preparation method for medical hig...

Embodiment 3

[0054] Such as figure 1 As shown, the medical high-gloss waterproof digital inkjet printing color film includes a substrate 1 and a coating on the substrate 1, the substrate 1 is a high-gloss PET sheet, and the coating includes a high-gloss waterproof ink-absorbing layer 2 , antistatic layer 4 and adhesive layer 3; one side of substrate 1 is coated with high-gloss waterproof ink-absorbing layer 2, the other side of substrate 1 is coated with adhesive layer 3, and the other side of adhesive layer 3 is coated with antistatic layer 4.

[0055] The high-gloss waterproof ink-absorbing layer includes the following components: 10kg of SPL-100 aluminum powder from Guangzhou Huigu Chemical Co., Ltd., 1kg of adhesive PVA235, 0.3kg of dispersant, 3kg of color-fixing agent, and 0.48kg of water-based whitening agent , polyether surfactant SN-126 0.2kg, pH regulator 5kg, deionized water 80kg, boric acid 0.01kg, n-butanol 0.01kg.

[0056] A preparation method for medical high-gloss waterpr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com