Magnetic composite microspheres with Raman-enhanced characteristic as well as preparation method and application thereof

A technology of magnetic composite microspheres and characteristics, applied in the direction of microsphere preparation, Raman scattering, microcapsule preparation, etc., to achieve the effects of fast magnetic response, uniform particle size distribution, and significantly good Raman signal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

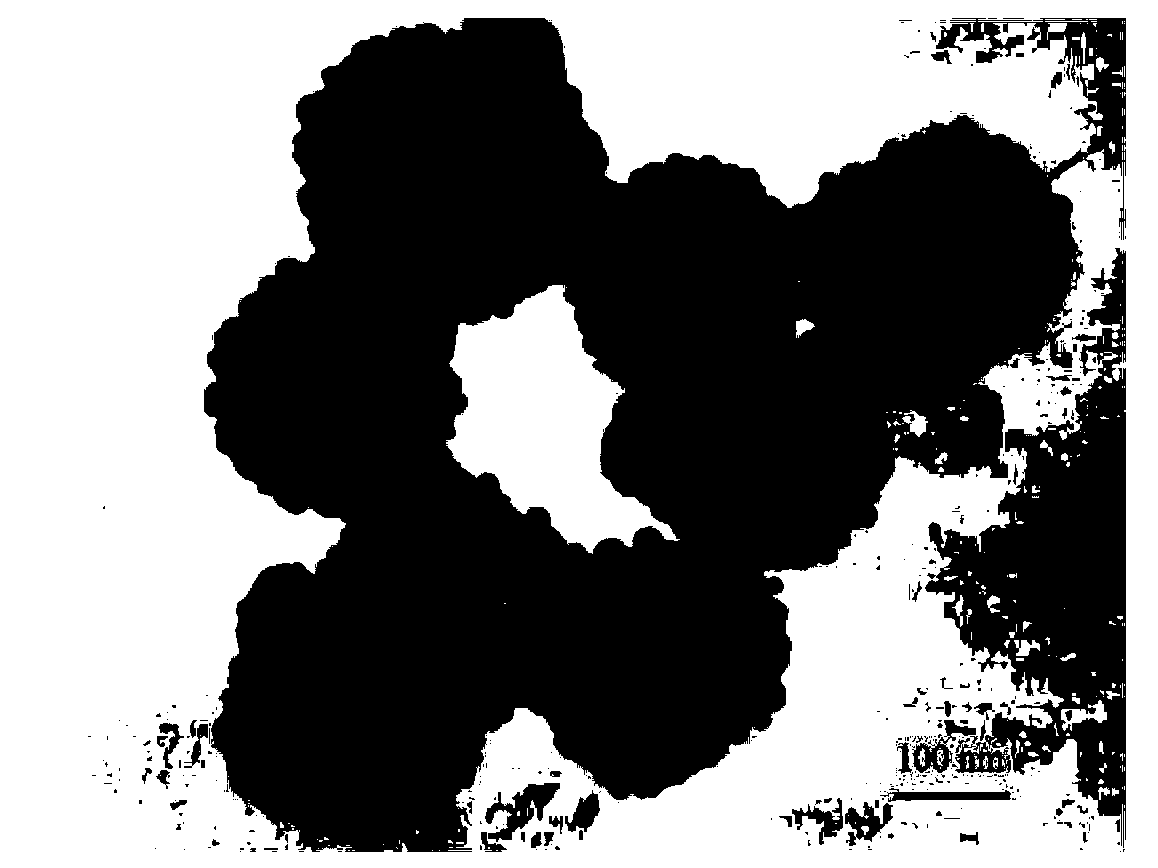

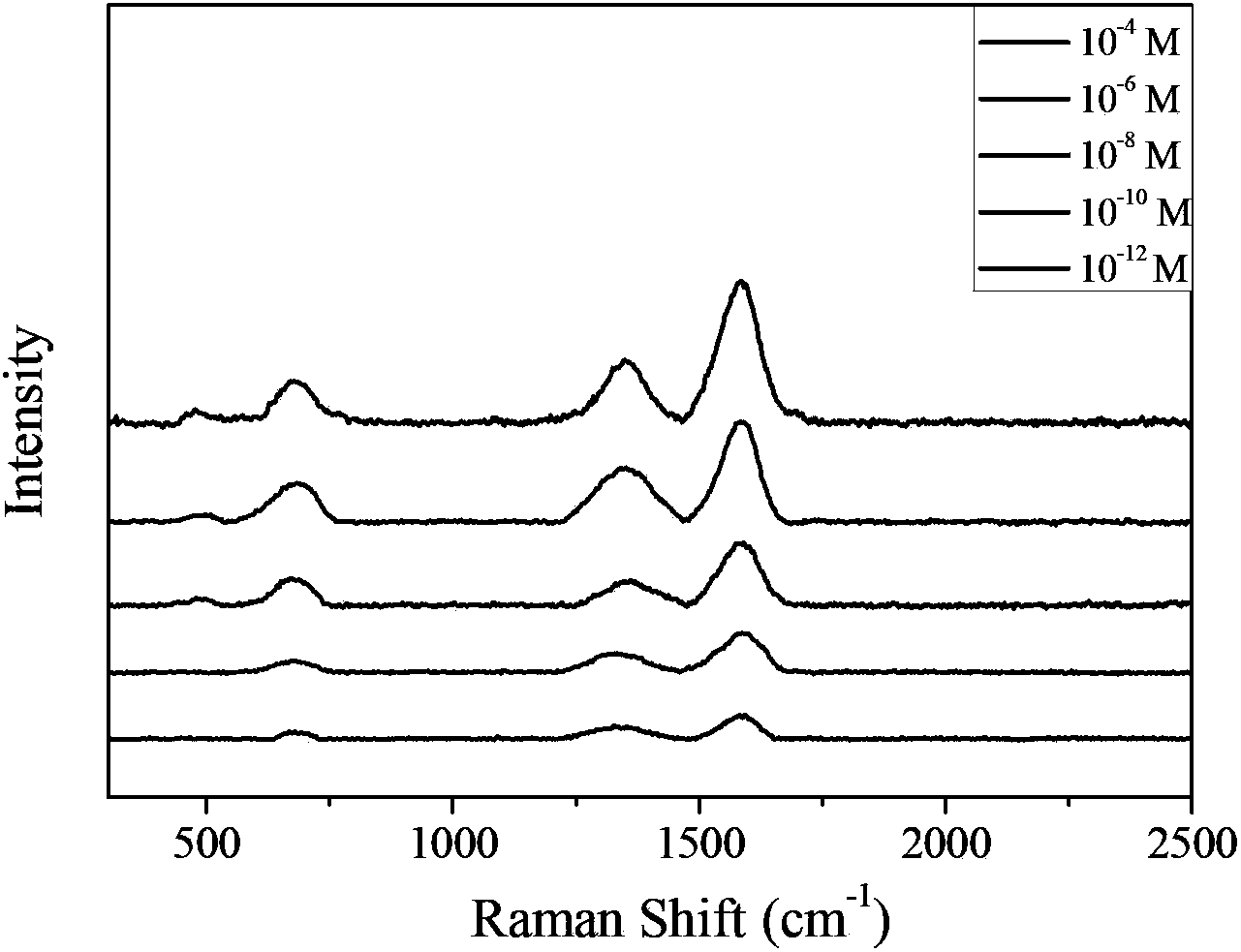

[0024] Example 1 Prepare a core-shell Fe with a magnetic core of about 180 nm, a carbon layer thickness of about 20 nm, and a silver nanoparticle shell of about 5 nm. 3 o 4 CAg microspheres and their application to detect different concentrations of PCP solutions

[0025] (1) Preparation of Fe 3 o 4 C

[0026] Dissolve 0.5g of ferrocene in 35mL of acetone, add 2.0mL of hydrogen peroxide while stirring magnetically, and then place it in a stainless steel autoclave with Teflon lining, and place the autoclave in an oven at 220°C for 24h. Take it out, let it cool to room temperature with tap water; separate the product by magnetic separation, wash with acetone and absolute ethanol to remove unreacted reactants, and finally disperse the product in absolute ethanol for later use;

[0027] (2) Preparation of Fe 3 o 4 CAg

[0028] 20mg of the Fe prepared in the above step (1) 3 o 4 Add C composite microspheres, 200mg silver nitrate, 0.04mL n-butylamine and 60mL absolute ethan...

Embodiment 2

[0031] Example 2 Prepare a core-shell Fe with a magnetic core of about 150 nm, a carbon layer thickness of about 20 nm, and a silver nanoparticle shell of about 10 nm. 3 o 4 CAg microspheres and PCP solutions used to detect different concentrations

[0032] (1) Fe 3 o 4 The preparation method of C is the same as the step (1) of the above-mentioned embodiment 1; wherein, the difference is that the ferrocene addition is changed from 0.5g to 0.3g;

[0033] (2) Fe 3 o 4 The preparation method of CAg is the same as the step (2) of the above-mentioned embodiment 1; wherein, the difference is that the consumption of silver nitrate is changed from 200mg to 400mg;

[0034] (3) Using Fe 3 o 4 CAg detects the test method of the SERS spectrum of the PCP solution of different concentrations with the step (3) of above-mentioned embodiment 1; Wherein, in the present embodiment, because magnetic core is smaller, so magnetic separation speed is slower than embodiment 1 (magnetic separat...

Embodiment 3

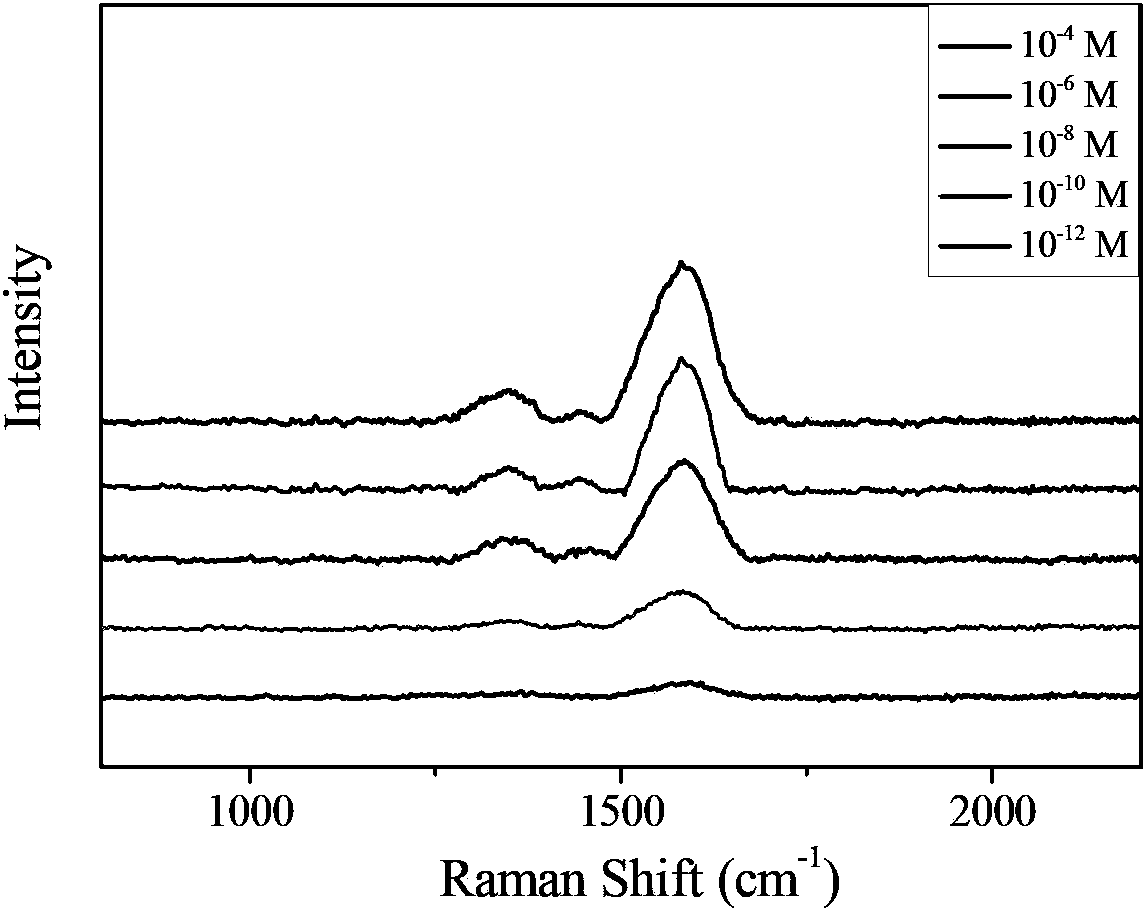

[0035] Example 3 Prepare a core-shell Fe with a magnetic core of about 180 nm, a carbon layer thickness of about 10 nm, and a silver nanoparticle shell of about 10 nm. 3 o 4CAg microspheres and used to detect different concentrations of DEHP solutions

[0036] (1) Fe 3 o 4 The preparation method of C is the same as the step (1) of the above-mentioned embodiment 1, wherein, the difference is that the amount of hydrogen peroxide is changed from 2.0mL to 1.0mL;

[0037] (2) Fe 3 o 4 The preparation method of CAg is the same as the step (2) of the above-mentioned embodiment 1, wherein, the difference is that the consumption of silver nitrate is changed from 200mg to 400mg;

[0038] (3) Using Fe 3 o 4 The test method of CAg detecting the SERS spectra of DEHP solutions with different concentrations is the same as the step (3) of the above-mentioned embodiment 1, wherein the difference is that the detected object is changed from PCP to DEHP.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com