Frozen noodles and manufacturing process therefor

A manufacturing method and technology of frozen noodles, applied in food preparation, application, food science, etc., to achieve the effect of preventing deterioration of appearance or taste and excellent resistance to deterioration over time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1~8)

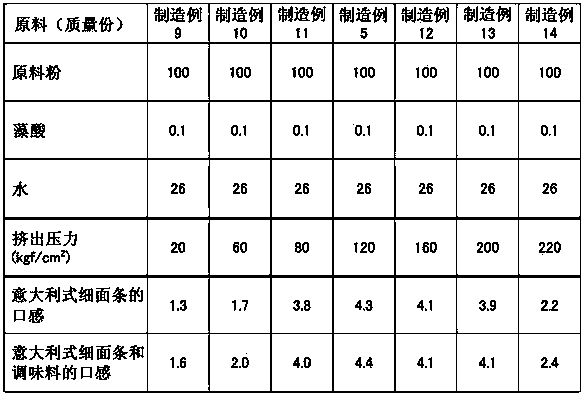

[0038] Alginic acid was mixed in the amount shown in Table 2 below with respect to 100 parts by mass of durum wheat flour, and 26 parts by mass of water was further added and kneaded to prepare dough. Using a pasta maker, the dough was subjected to a pressure reduction of -600mmHg and 120kgf / cm 2 Under the pressure condition of extrusion noodle making, 8 kinds of raw spaghetti (thickness 1.8mm) were obtained. The obtained raw spaghetti was boiled in hot water for 5 minutes, and water cooled to prepare boiled spaghetti. The boiled spaghetti was taken out at 180g per plate and distributed to trays (160mm×120mm; made of polypropylene), and on half of the trays, a commercially available canned minced meat seasoning (Nissin フーズ system) 100g. These were flash-frozen at -35 degreeC, and the frozen cooked spaghetti (one without seasoning and one with seasoning, respectively) of Production Examples 1-8 were prepared.

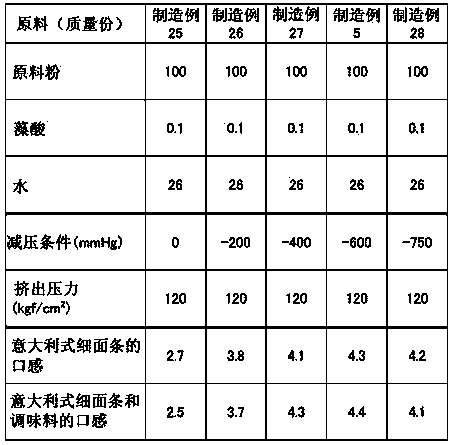

manufacture example 9~14

[0046] The frozen cooked spaghetti of Production Examples 9 to 14 (respectively unflavored and flavored).

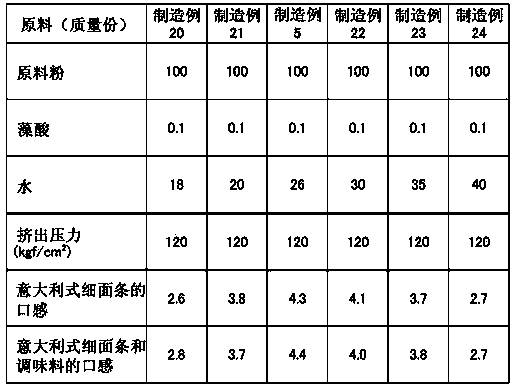

manufacture example 15~19

[0052] Alginic acid was mixed in the amount shown in Table 4 below with respect to 100 parts by mass of durum wheat flour, and 26 parts by mass of water was further added and kneaded to prepare a dough. Using a pasta maker, the dough was subjected to a pressure reduction of -600mmHg and 120kgf / cm 2 The noodles were extruded under the pressure conditions to obtain raw spaghetti (thickness 1.8mm).

[0053] The obtained raw spaghetti was divided into 200-g portions, and it was rapidly frozen at -35 degreeC, and the frozen raw spaghetti of manufacture examples 15-19 were manufactured.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com