Production equipment for small-grain tea

A production equipment and a technology for small-grain tea, applied in the field of small-grain tea production equipment, can solve problems such as being insufficient to meet the requirements of an efficient and fine industrial tea-making process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

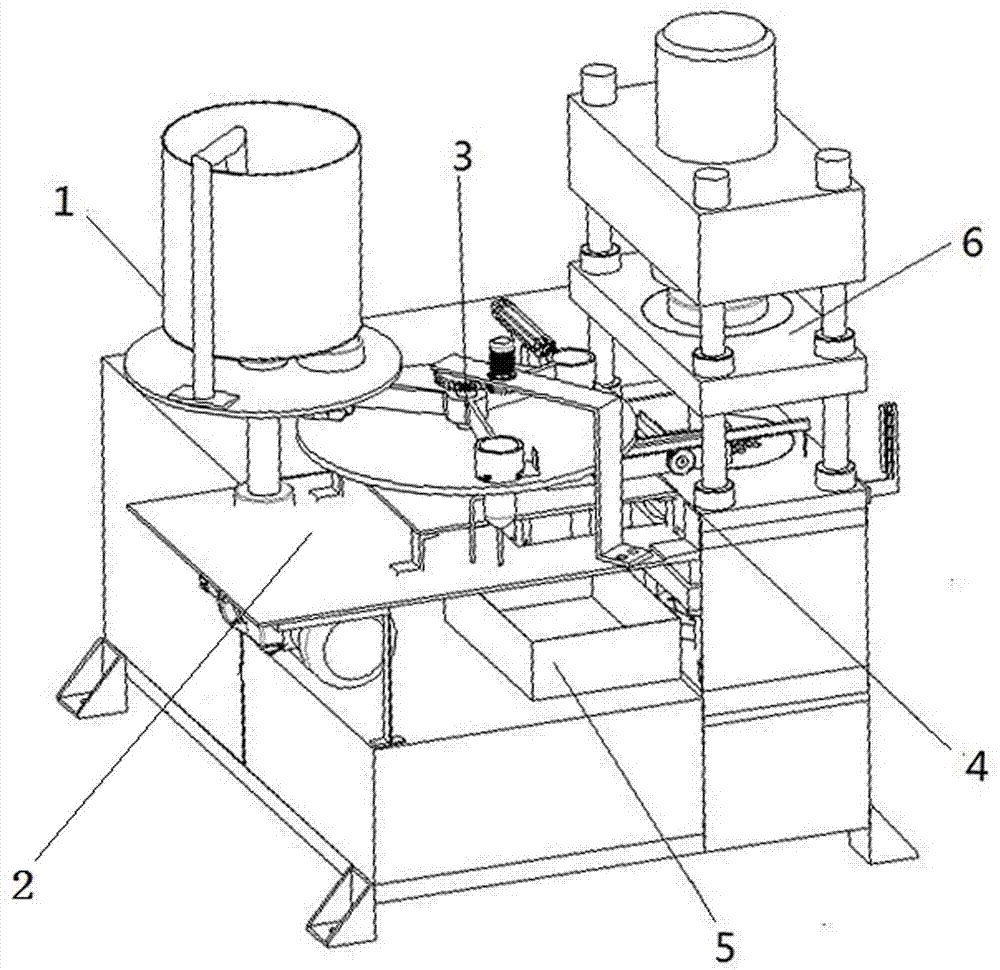

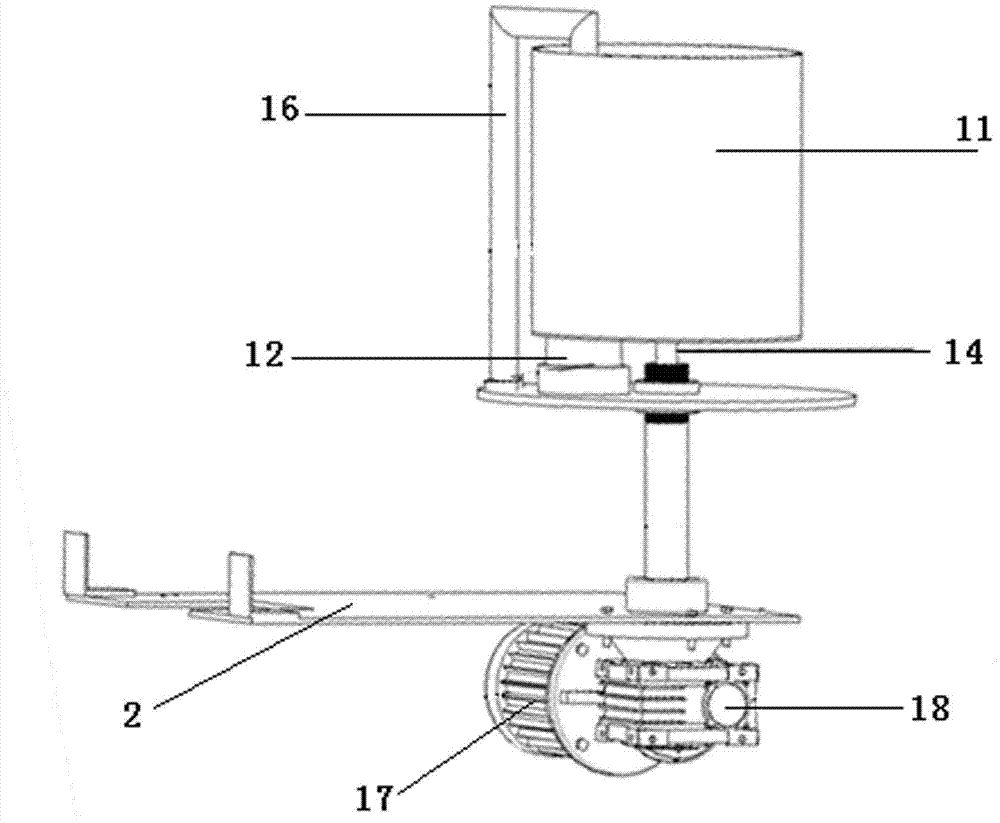

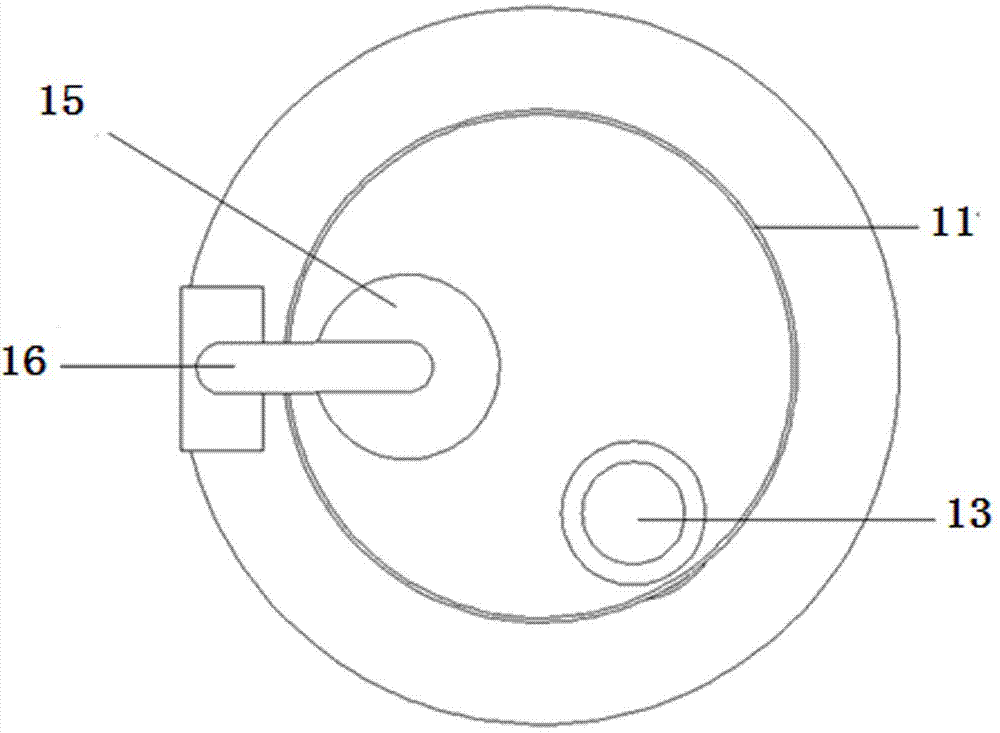

[0037]The present invention is made up of small tea production equipment by unloading device 1, tea steaming device 3, spreading device 4, residual material recovery device 5, hydroforming device 6, support plate 2 and machine base, and described unloading device 1 is placed in the equipment The top, the machine base is placed at the bottom of the equipment, the hydroforming device 6 is placed on one side of the machine base, the support plate 2 is fixed on the machine base, one side of the support plate 2 is fixedly connected to the hydroforming device 6, and the tea steaming device 3 is placed on the unloading device 1, the feeding device 1 is connected to the tea steaming device 3 for feeding, the material spreading device 4 is placed under the tea steaming device 3, the material spreading device 4 and the tea steaming device 3 are placed on the support plate 2, and the tea material passes through the feeding device 1 pair Unloading, the tea material enters the tea steaming ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com