Alga-contained yoghourt and manufacturing method thereof

A seaweed and yogurt technology, applied in milk preparations, dairy products, applications, etc., can solve the problems of reduced utilization rate, easy loss, and inability of wakame, and achieve the effect of improving utilization rate, good taste, and maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

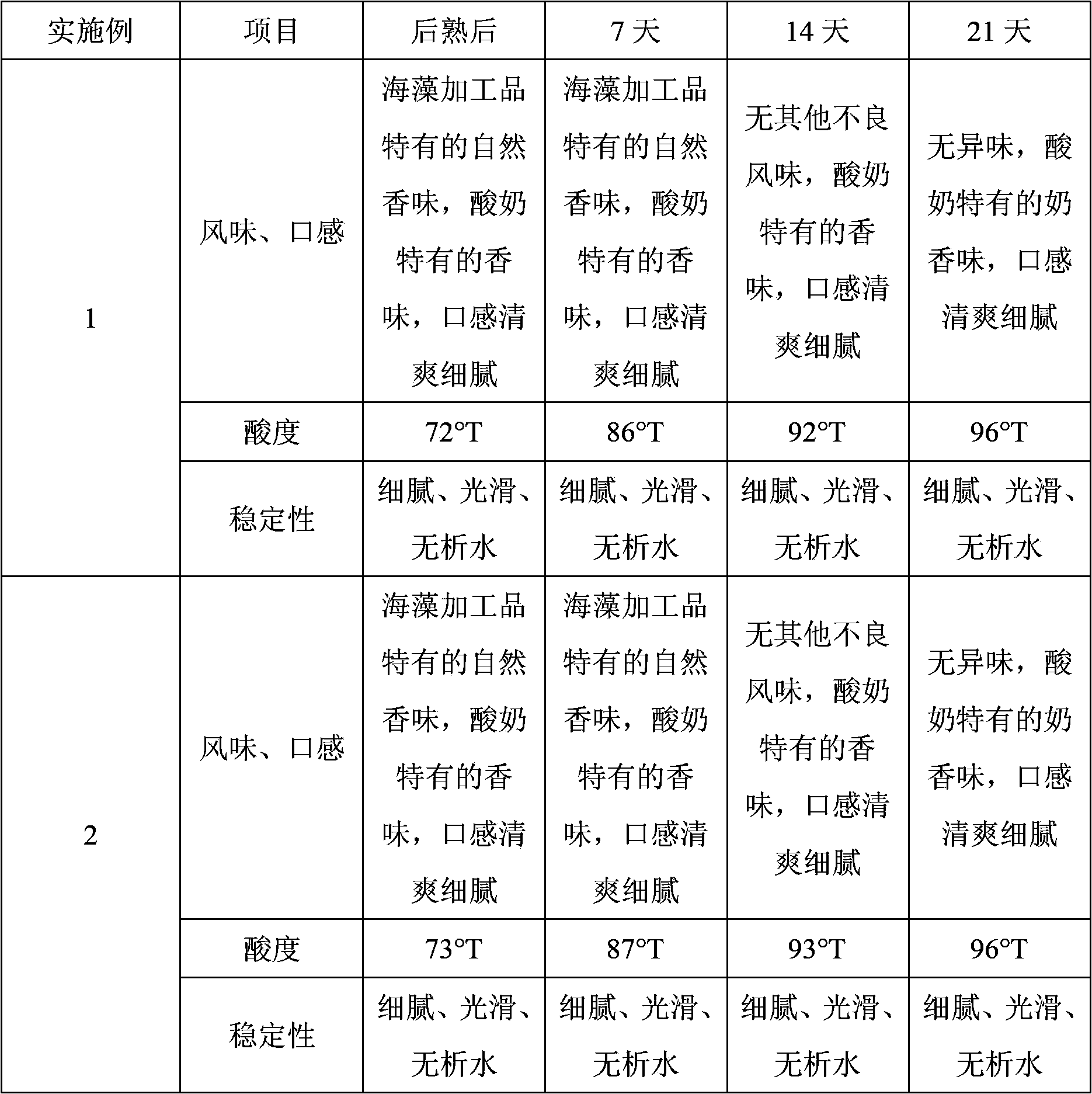

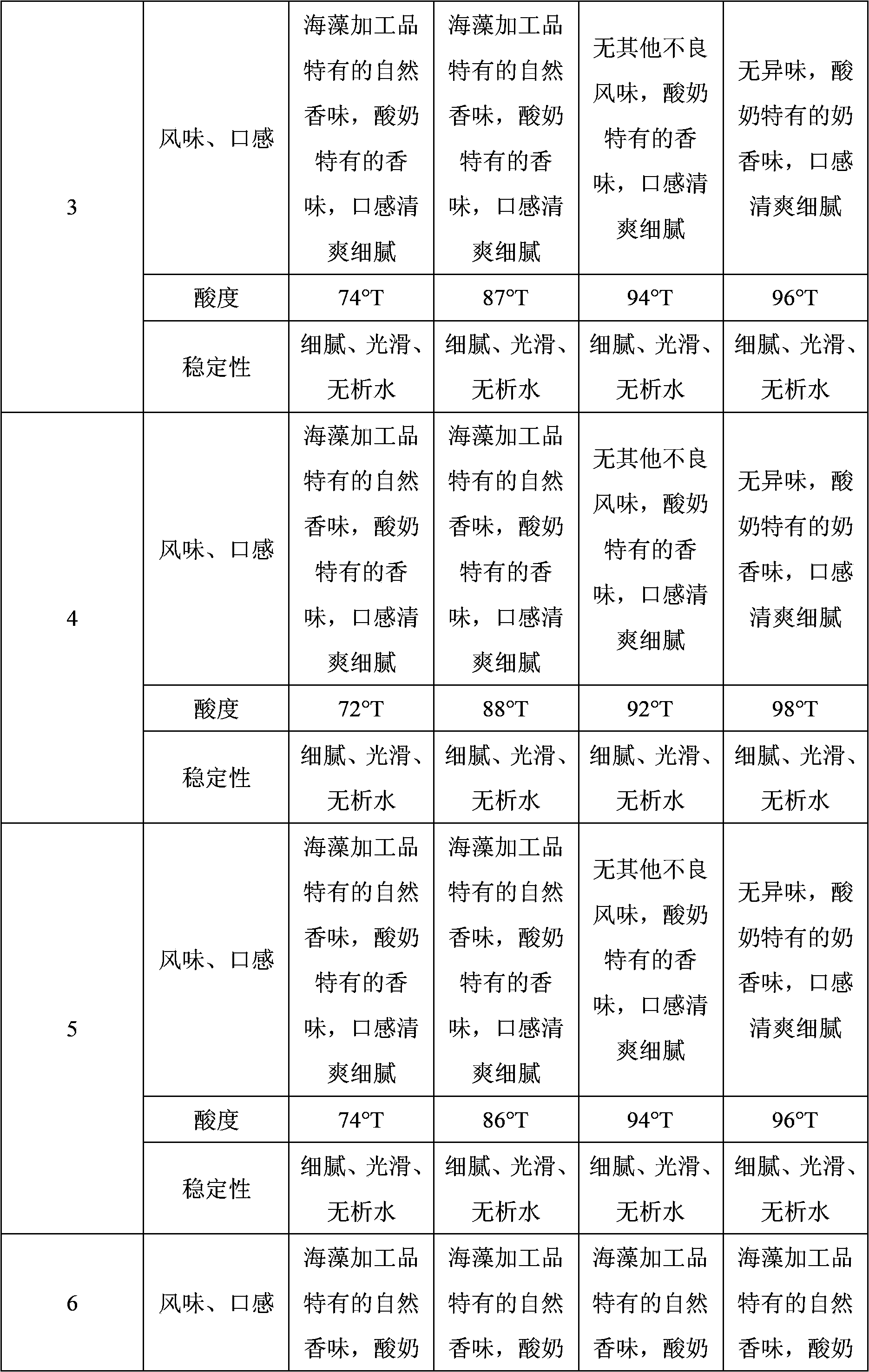

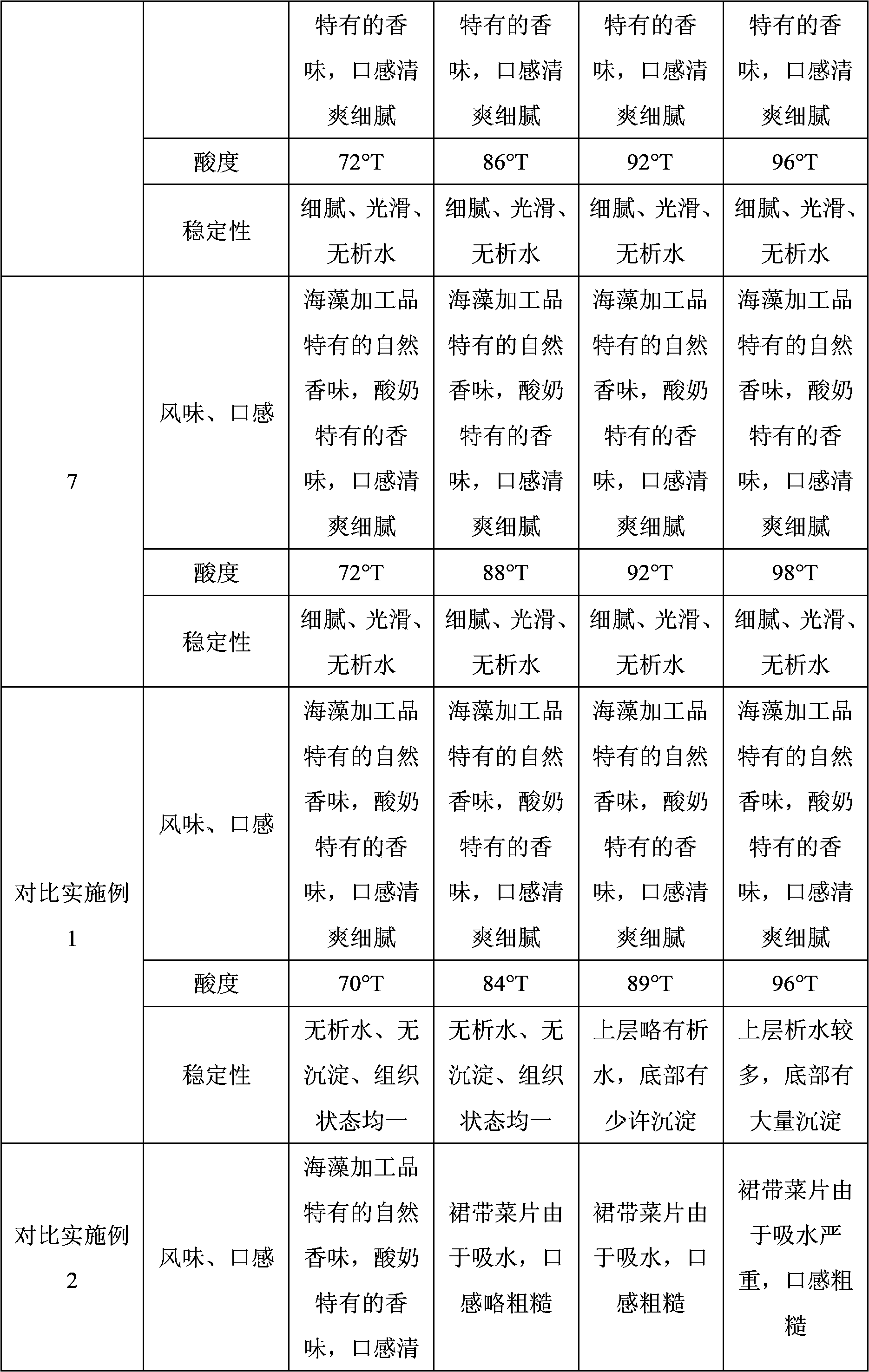

Examples

Embodiment 1

[0032] Embodiment 1. Laver yogurt one and its preparation method

[0033] This embodiment is a production of laver yogurt, which is characterized by mixing laver powder and other raw materials and directly participating in the fermentation product.

[0034] 1. Laver yogurt formula: white sugar 6.0%, concentrated whey protein 0.6%, pectin 0.04%, seaweed powder (150 mesh) 3.0%, fermentation strains (Streptococcus thermophilus, Lactobacillus bulgaricus, Lactobacillus acidophilus) 0.008%, the balance of fresh milk.

[0035] 2. The yogurt of this embodiment is produced according to the following agitated yogurt process method:

[0036] 1. Process flow:

[0037] Raw milk inspection → ingredients and standardization → preheating → degassing → homogenization → sterilization → cooling → inoculation → stirring → insulation and fermentation → demulsification → cooling → filling → refrigerated and cooked.

[0038] 2. Process description:

[0039] 2.1 Milk inspection: mainly for sensory, acidity, fat...

Embodiment 2

[0053] Example 2: Laver yogurt 2 and its preparation method

[0054] This embodiment is a production of laver yogurt, which is characterized by mixing laver powder and other raw materials and directly participating in the fermentation product.

[0055] 1. Laver yogurt formula: white sugar 6.0%, whey protein concentrate 0.6%, gelatin 0.1%, laver powder (150 mesh) 3.0%, fermentation strains (Streptococcus thermophilus, Lactobacillus bulgaricus, Lactobacillus acidophilus) 0.008 %, the remaining amount of fresh milk.

[0056] 2. The yogurt of this embodiment is produced according to the following agitated yogurt process method:

[0057] 1. Process flow:

[0058] Raw milk inspection → ingredients and standardization → preheating → degassing → homogenization → sterilization → cooling → inoculation → stirring → insulation and fermentation → demulsification → cooling → filling → refrigerated and cooked.

[0059] 2. Process description:

[0060] 2.1 Milk inspection: mainly for sensory, acidity, f...

Embodiment 3

[0073] Embodiment 3 Wakame yogurt and its preparation method

[0074] This embodiment is a preparation of wakame yogurt, which is characterized in that the wakame slices are mixed with yogurt online and then filled.

[0075] 1. Wakame yogurt formula: white sugar 8.0%, concentrated whey protein 0.2%, starch 0.4%, gelatin 0.1%, pectin 0.04%, wakame flakes (particle size 5mm×5mm×5mm, thickness 2mm) 5.0 %, fermentation bacteria (Streptococcus thermophilus, Lactobacillus bulgaricus, Bifidobacterium) 0.01%, fresh milk balance.

[0076] 2. The yogurt of this embodiment is produced according to the following agitated yogurt process method:

[0077] 1. Process flow:

[0078] Raw milk inspection → ingredients and standardization → preheating → degassing → homogenization → sterilization → cooling → inoculation → stirring → insulation and fermentation → demulsification → cooling → filling → refrigerated and cooked.

[0079] 2. Process description:

[0080] 2.1 Milk inspection: mainly for sensory, ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com