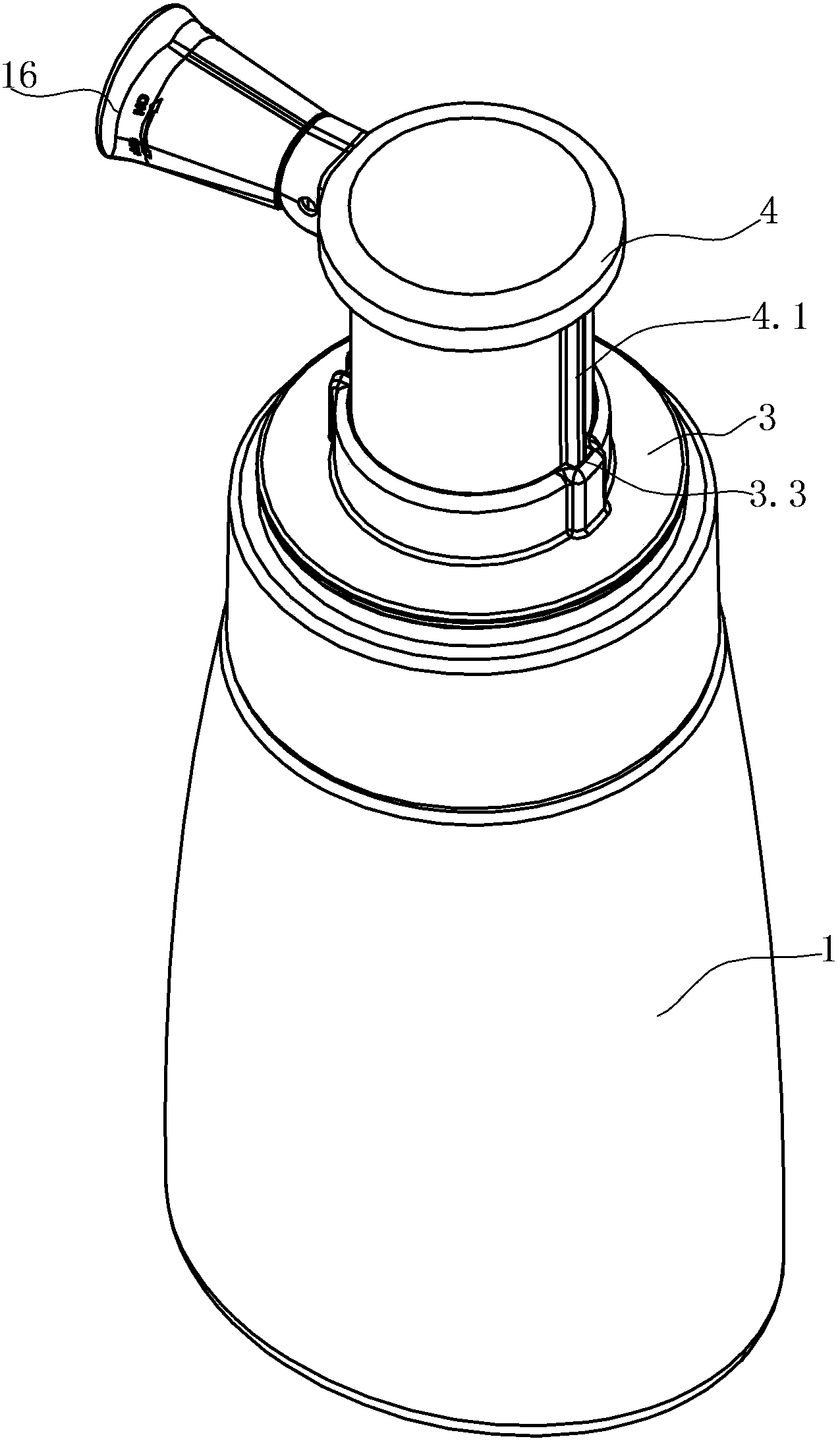

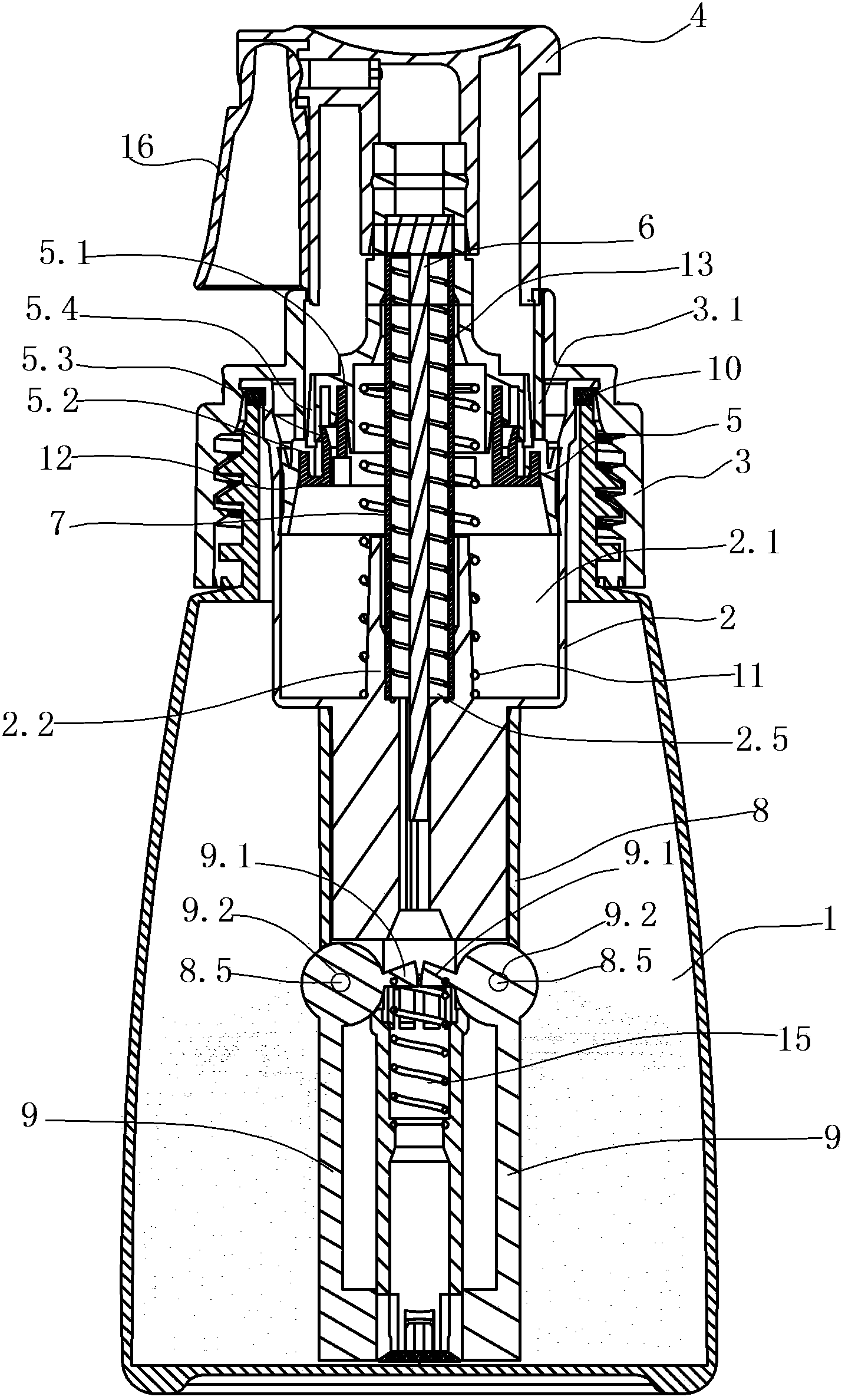

Powder sprayer

A sprayer and powder technology, applied in the field of dry powder sprayers, can solve the problems that dry powder cannot pass smoothly, powder cannot be sprayed for use, and the conveying pipe is used for a long time, so as to achieve good powder spraying effect, improved sealing performance, and improved powder output efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0040] Implementation example 1

[0041] Such as Figure 1-12 As shown, a powder sprayer includes main components such as a bottle body 1, a pump body 2, a bottle cap 3, a head cap 4, a piston 5, a push rod 6, a silicone tube 7, a connector 8, and a manipulator 9. Body 1 is hollow and transparent, made of plastic, and its inner cavity is used to hold dry powder, such as prickly heat powder. 2 Place the edge on the opening of the bottle body 1, and an O-shaped sealing gasket 10 is lined between the edge and the bottle mouth. The bottle cap 3 is fixed on the upper part of the bottle body 1 through screw connections, and the edge of the pump body 2 is connected to the The bottle mouth is compressed and fixed, the guide groove 3.3 is formed on the bottle cap 3, and the matching guide rib 4.1 is formed on the rear portion of the head cap 4, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com