Method for separating a sheet-material tube containing product stacks, packaging installation for implementing the method, and perforated tubular sheet material

A technology for packaging equipment and products, applied in the directions of packaging, multiple packages, transportation and packaging, which can solve problems such as film tearing and achieve high throughput.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

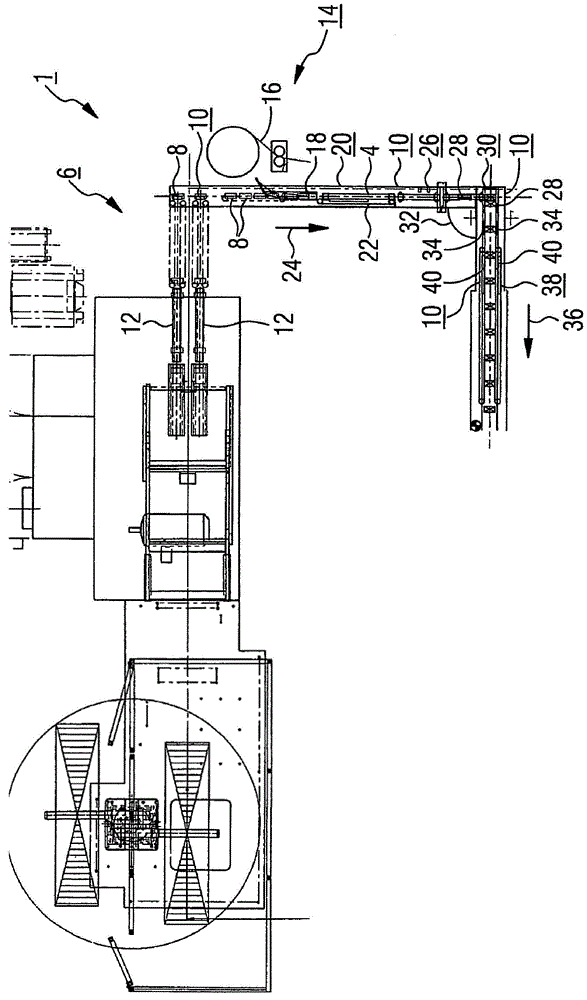

[0027] attached figure 1 The packaging equipment shown can be used to pack hygiene products into bags. In this embodiment, paper towels should be used as sanitary products, that is, they should be put into a packaging bag in batches of ten pieces as a stack of paper towels. Of course, other batches can be used instead, for example three or five paper towels can be packaged in bags, or other hygienic products can be packaged, such as sanitary pads, sanitary napkins or similar products.

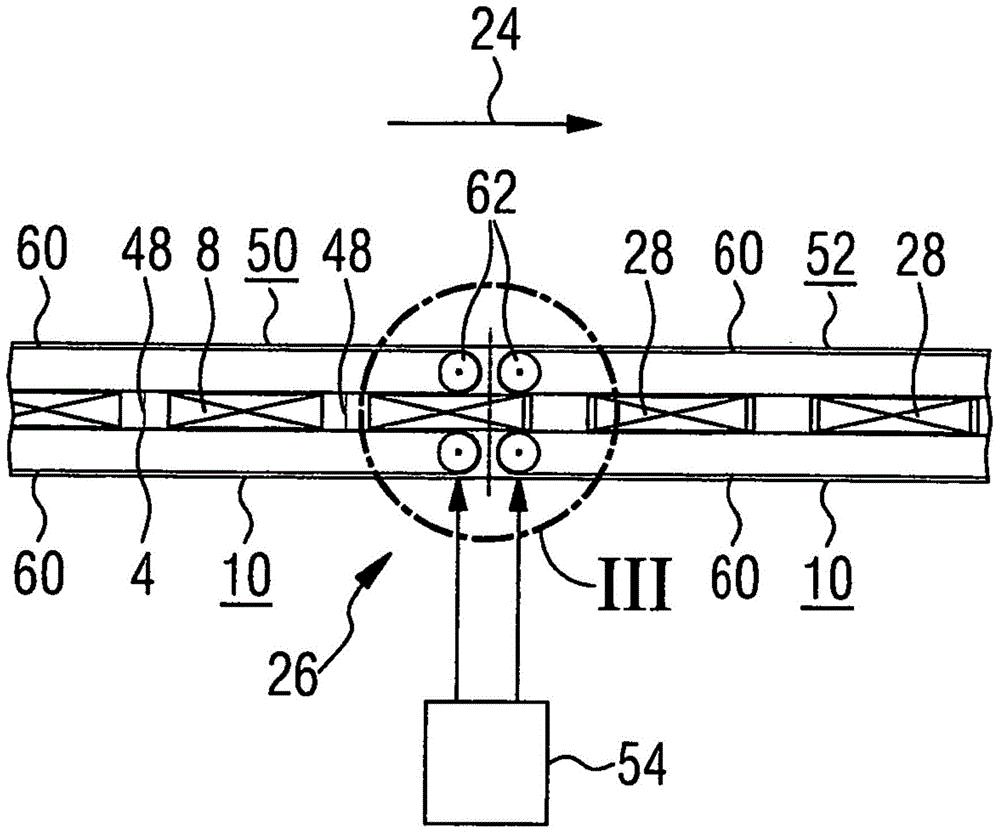

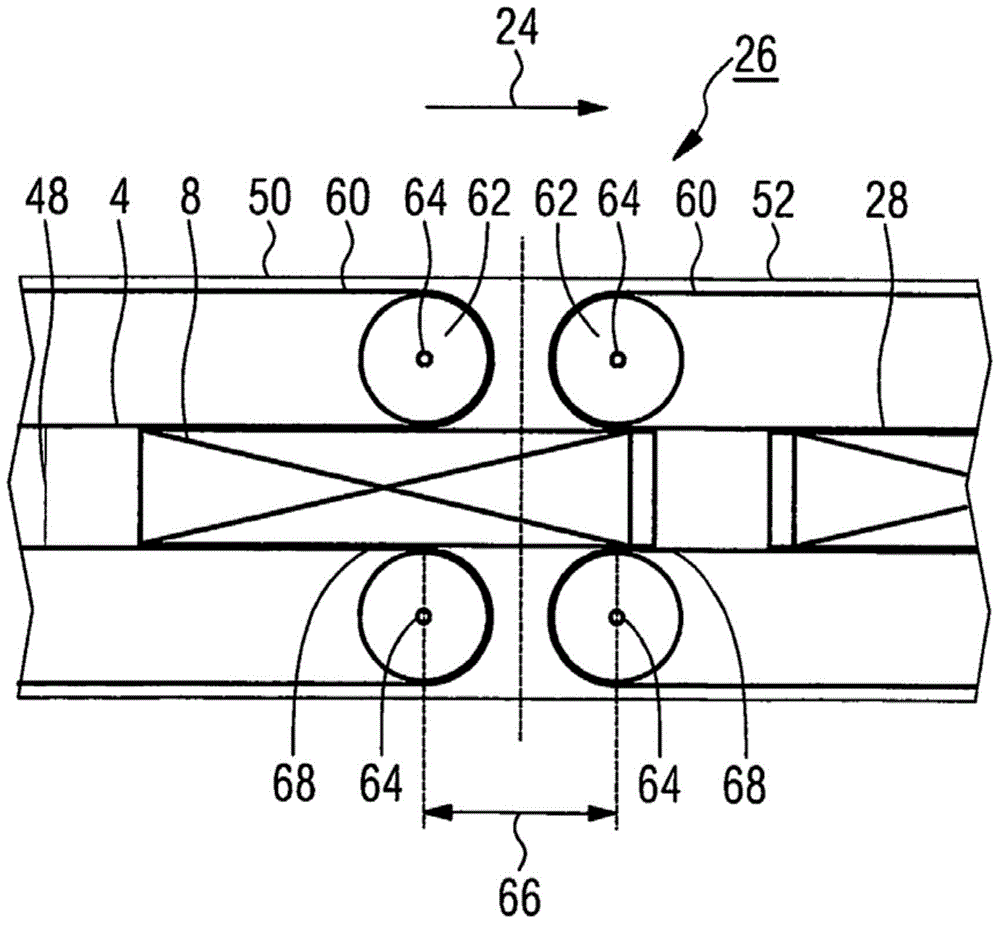

[0028] The packaging equipment 1 is designed as a film tube packaging machine. First, the paper towels to be packaged are packed into the film tubes 4 batch by batch or stacked one by one. The packaging equipment 1 includes a feeding unit 6 through which the product stacks The conveying system 10 is supplied with tissues in the form of stacks 8, said product stacks each comprising ten stacked tissues. In this embodiment, the feeding unit 6 is of double-track type, that is, two feeding rails 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com