Novel energized arrester tester and arrester detection method

A technology of lightning arrester and tester, which is applied in the field of lightning arrester detection, can solve problems such as loss, power grid maintenance damage, power outage economy, failure to find lightning arrester defects in time, and achieve the effect of improving accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

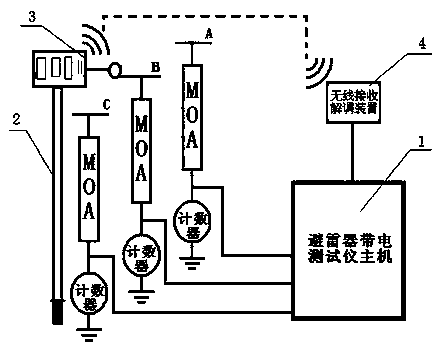

[0026] Such as figure 1 and figure 2 As shown, the new lightning arrester live tester includes a lightning arrester live tester host 1, a wireless receiving demodulation device 4, an insulating operating rod 2 and is used to measure the voltage phase data of the device under test and send the data to the lightning arrester live tester host The contact voltage probe 3 is connected to the top of the insulating operating rod 2 .

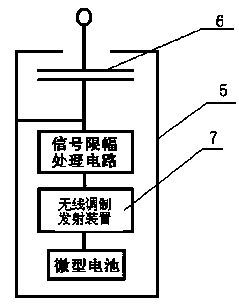

[0027] The contact voltage probe includes a shielding case 5 , a micro battery, a capacitive electric field sensor 6 and a wireless modulation transmitter 7 . The contact voltage probe 3 is not connected with the equipment under test, the ground personnel and the host 1 of the lightning arrester electrification tester.

[0028] When using the above-mentioned new lightning arrester live tester to test the lightning arrester, the staff holds the insulating operating rod and directly touches the working live part of the equipment under test with the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com