Automatic visual detection method and device for Mura defects of thin film transistor liquid crystal display (TFT-LCD) process

An automatic detection and visual technology, applied in the direction of optical testing flaws/defects, optics, instruments, etc., can solve problems such as the difficulty of manual detection methods to meet product quality and production efficiency, the lack of uniform judgment standards for defect levels, and the increase of liquid crystal displays. Achieve the effect of avoiding a large number of floating-point operations, facilitating subsequent processing, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

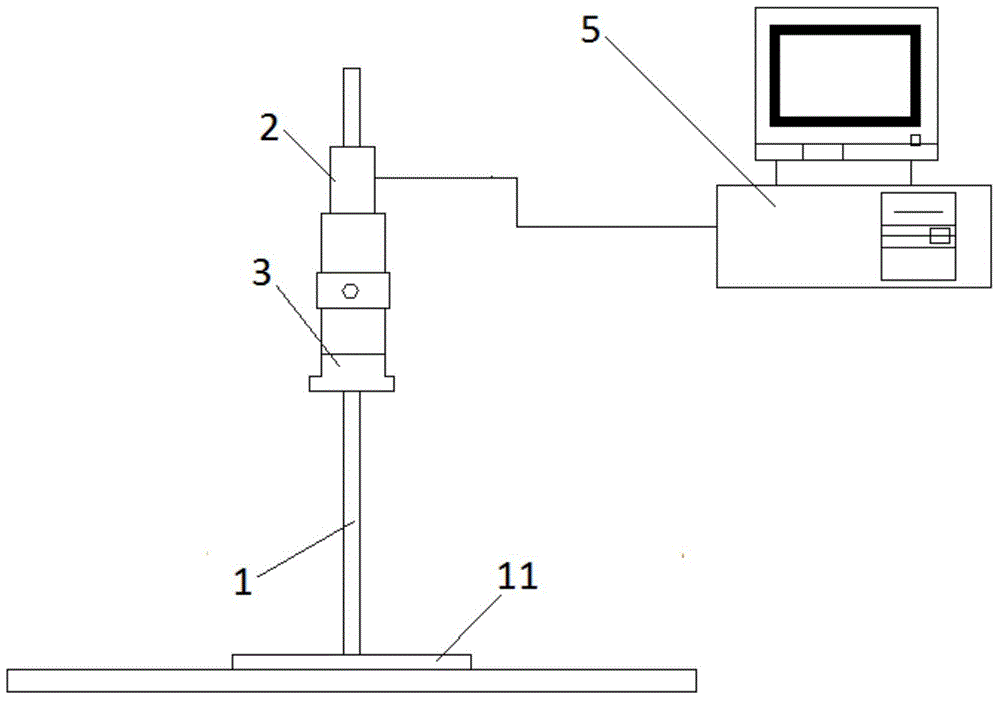

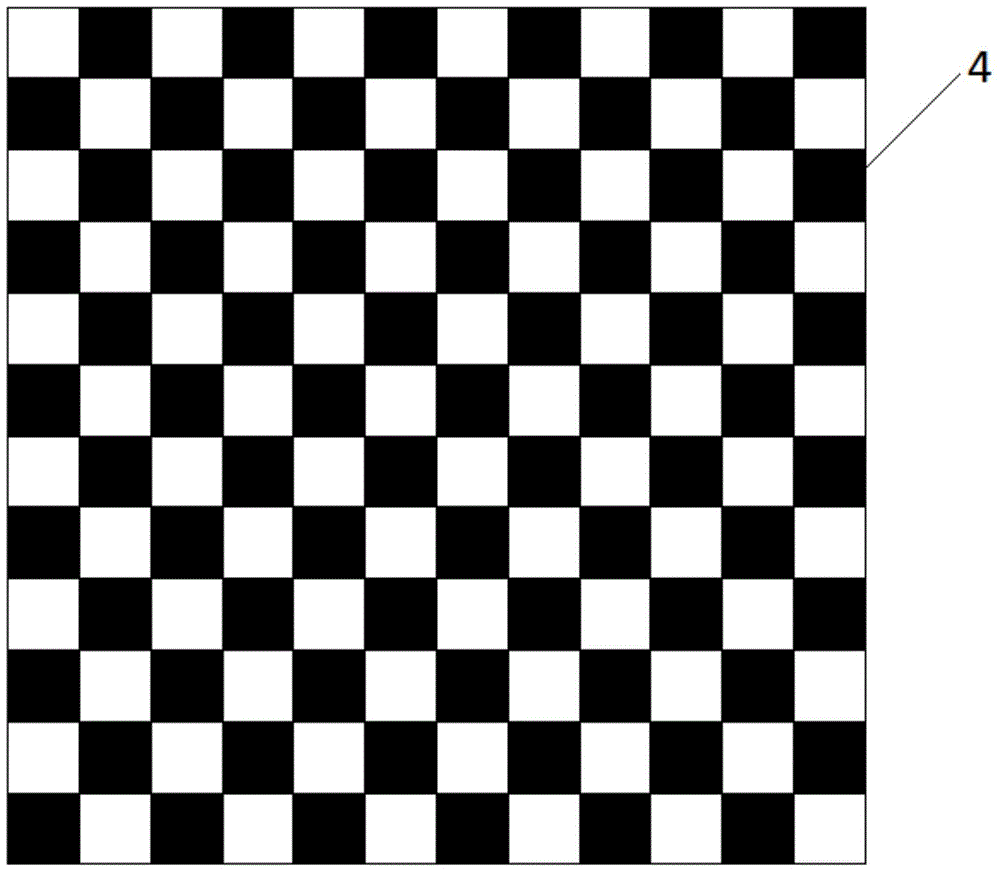

[0038] Refer to Figure 1-2 , The MURA vision automatic inspection device of the TFT-LCD process includes a fixing device 1, a CCD camera device 2, a lens 3, and a standard square angle Figure 4 And the computer 5, the fixing device 1 is equipped with a fixed jig 11 of the measured object, and the square angle standard Figure 4 Laying on the upper surface of the fixed fixture 11 of the measured object, the CCD camera device 2 is installed on the fixed device 1 and above the fixed fixture 11 of the measured object, the lens 3 is set on the CCD camera device 2, and the CCD camera device 2 passes The connecting line is connected with the computing card set on the computer 5.

[0039] Among them, the computer 5 is provided with a low-pass filter based on discrete Fourier change and a GPU.

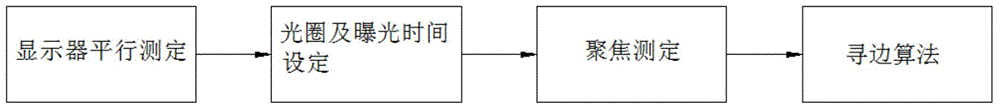

[0040] Refer to Figure 3-7 , A MURA vision automatic inspection method for TFT-LCD manufacturing process, which includes

[0041] Image preparation process:

[0042] 1) Place the object to be teste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com