Fixing frame structure for mounting weighing sensor

A technology of weighing sensor and fixing frame, which is applied to the detailed information of weighing equipment, weighing equipment and instruments using elastically deformable parts, etc., can solve the problem of reducing the service life of power supply, short circuit of switching power supply, and increasing production and maintenance costs. and other problems, to achieve the effect of good mechanical strength, convenient maintenance, reduction of work increase and re-measurement costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

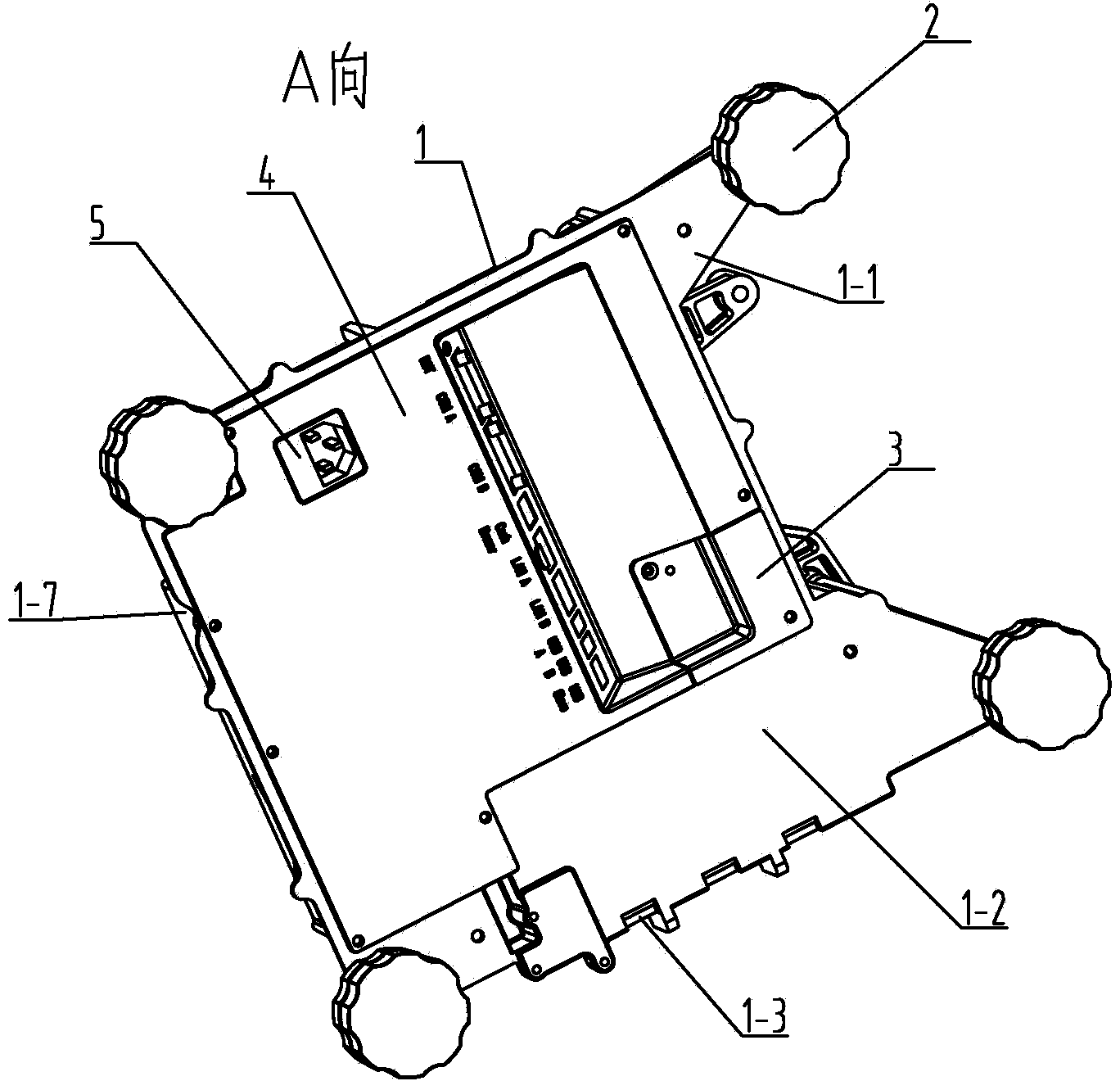

[0014] See Figure 1~3 Shown, a kind of fixed frame structure of installing weighing sensor of the present invention, fixed frame 1 of the present invention comprises top board 1-6 is connected in the wall board 1-7 of top board 1-6 periphery and bottom plate 1-2, and this fixed frame 1. The overall structure is made of metal materials. There are multiple outer ribs 1-9 on the outer periphery of the wall panels 1-7, and a battery compartment seat 1 connected to the bottom panel 1-2 is provided on the outer side of the wall panels 1-7 on one side. -4, the outer wall of the battery compartment seat 1-4 is provided with a limit notch 1-3, when the upper case is installed on the fixed frame 1 and covered on the fixed frame 1, the battery compartment of the upper case is arranged on the side of the present invention The battery compartment or the upper part is provided with a limit block on the battery box placed in the battery compartment of the upper case, and the limit block is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com