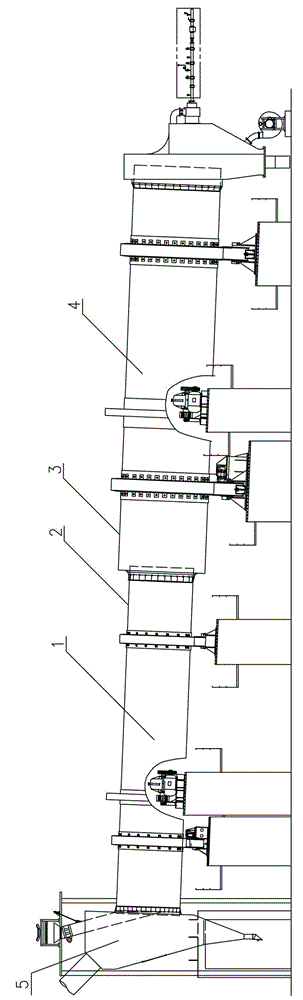

Environment-friendly tandem type drying and calcining kiln

A calcining kiln and tandem technology, which is applied in the improvement field of industrial lifting plate drying and calcining equipment, can solve the problems of dust pollution, leakage of the tandem drying and calcining kiln system, etc., so as to avoid leakage, improve environmental pollution problems and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

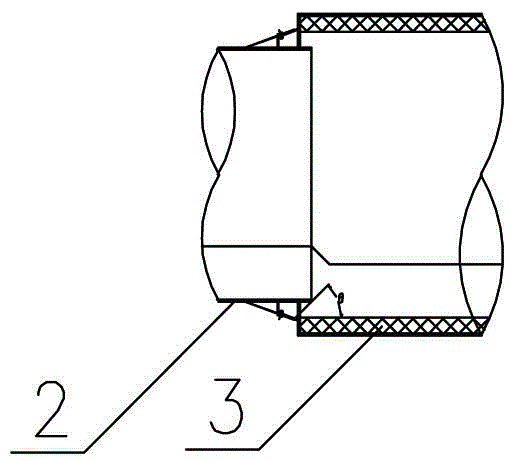

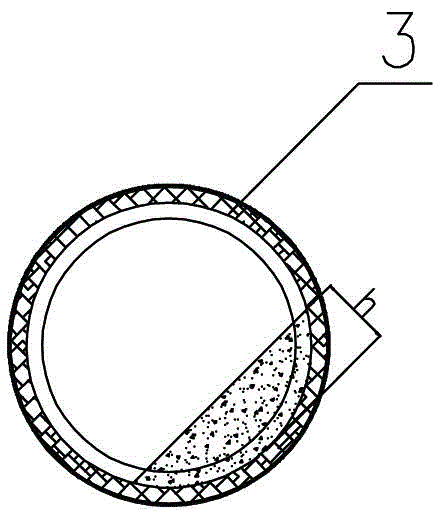

[0027] Example 1: see image 3 —5. The present invention includes a rotary dryer 1 and a rotary calciner 3, both of which are provided with a cylinder, wherein the diameter of the dryer cylinder 2 is relatively small, and its butt joint is placed in the calciner cylinder 3, especially Yes: 21 pusher plates 5 are inserted into the ring on the butt end face of the dryer barrel 2, and the pusher plates 5 are arranged to push forward along the axial direction.

[0028] In this embodiment, the pusher plate 5 is arranged at an angle of 21° (adjustable in the range of 18-26°) to the end surface of the dryer barrel 2, that is, t=the pitch of the pusher plate is 4m.

[0029] In this embodiment, the pushing plate 3 is provided with a card slot, and the card slot is installed on the end face ring of the dryer barrel 1 and welded as a whole.

[0030] The length L=kh / tgθ of the pushing plate 3 described in this embodiment, the height H=kQ×tgθ×(36.896n×t×a×p×n×N) -1 . In the above formul...

example 2

[0045] Example 2: see image 3 —5. The present invention includes a rotary dryer 1 and a rotary calciner 3, both of which are provided with a cylinder, wherein the diameter of the dryer cylinder 2 is relatively small, and its butt joint is placed in the calciner cylinder 3, especially Yes: 18 pusher plates 5 are inserted into the ring on the butt end face of the dryer barrel 2, and the pusher plates 5 are arranged to push forward along the axial direction.

[0046] In this embodiment, the pusher plate 5 is arranged at an angle of 26° to the end surface of the dryer barrel 2, that is, t=the pitch of the pusher plate is 3m.

[0047] In this embodiment, 18 slots are uniformly distributed on the end face ring of the dryer barrel 2, and the pushing plate 5 is inserted into the slots and fixed by welding.

[0048] The length L=kh / tgθ of the pushing plate 3 described in this embodiment, the height H=kQ×tgθ×(36.896n×t×a×p×n×N) -1 . In the above formula:

[0049] k-safety factor, g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com