System and method of kerosene switching of active cooling subsonic combustion ramjet engine

A sub-combustion ramjet, active cooling technology, applied in ramjet engines, mechanical equipment, etc., can solve problems such as kerosene density reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other.

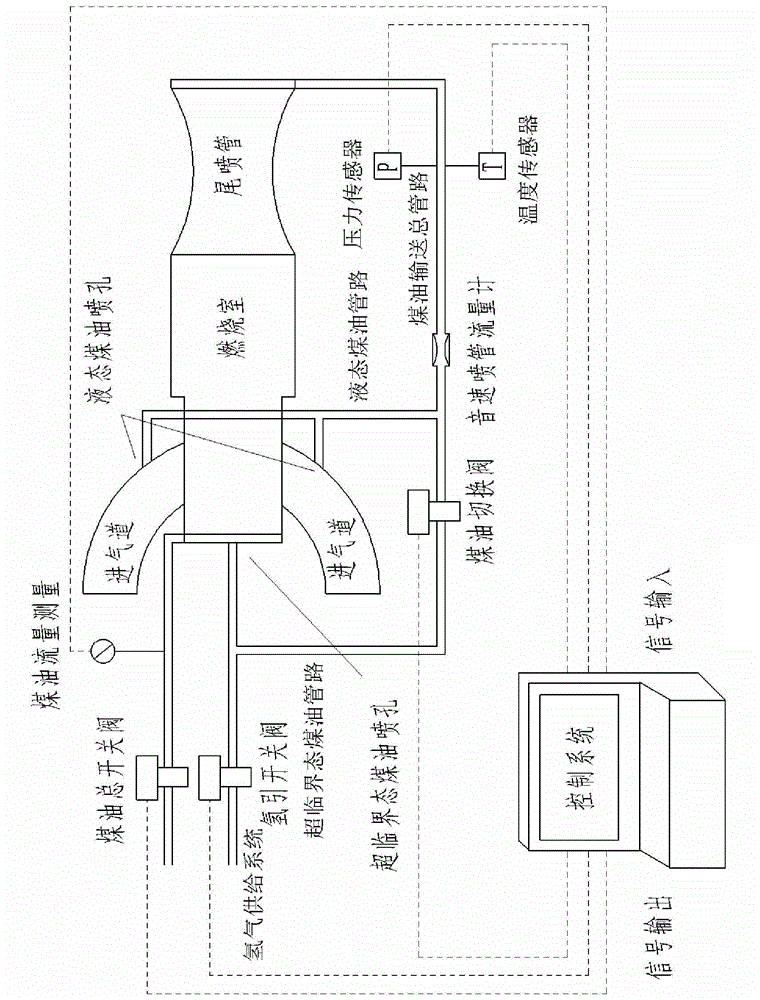

[0022] Such as figure 1 As shown, the main body of a subsonic combustion ramjet is composed of an intake port, a combustion chamber and an exhaust nozzle. The intake port is connected to the combustion chamber by two arc-shaped passages; the combustion chamber is circular in section and consists of two cylinders with different diameters; the exhaust pipe section is also circular, and the exhaust pipe shrinks first and then expands. The parts that need to be cooled in the experiment include the combustion chamber and the exhaust pipe. Cooling passages are provided in the walls of the combustion chamber and the exhaust pipe, and kerosene flows through the cooling passages to tak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com