Integrated turbine set based on permanent magnetic and magnetic suspension technologies

A turbine unit and magnetic levitation technology, applied in the direction of electromechanical devices, mechanical equipment, electric components, etc., can solve the problems of low efficiency, limited life and high cost of turbomachinery, and achieve the effect of improving overall efficiency and avoiding friction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in combination with specific embodiments.

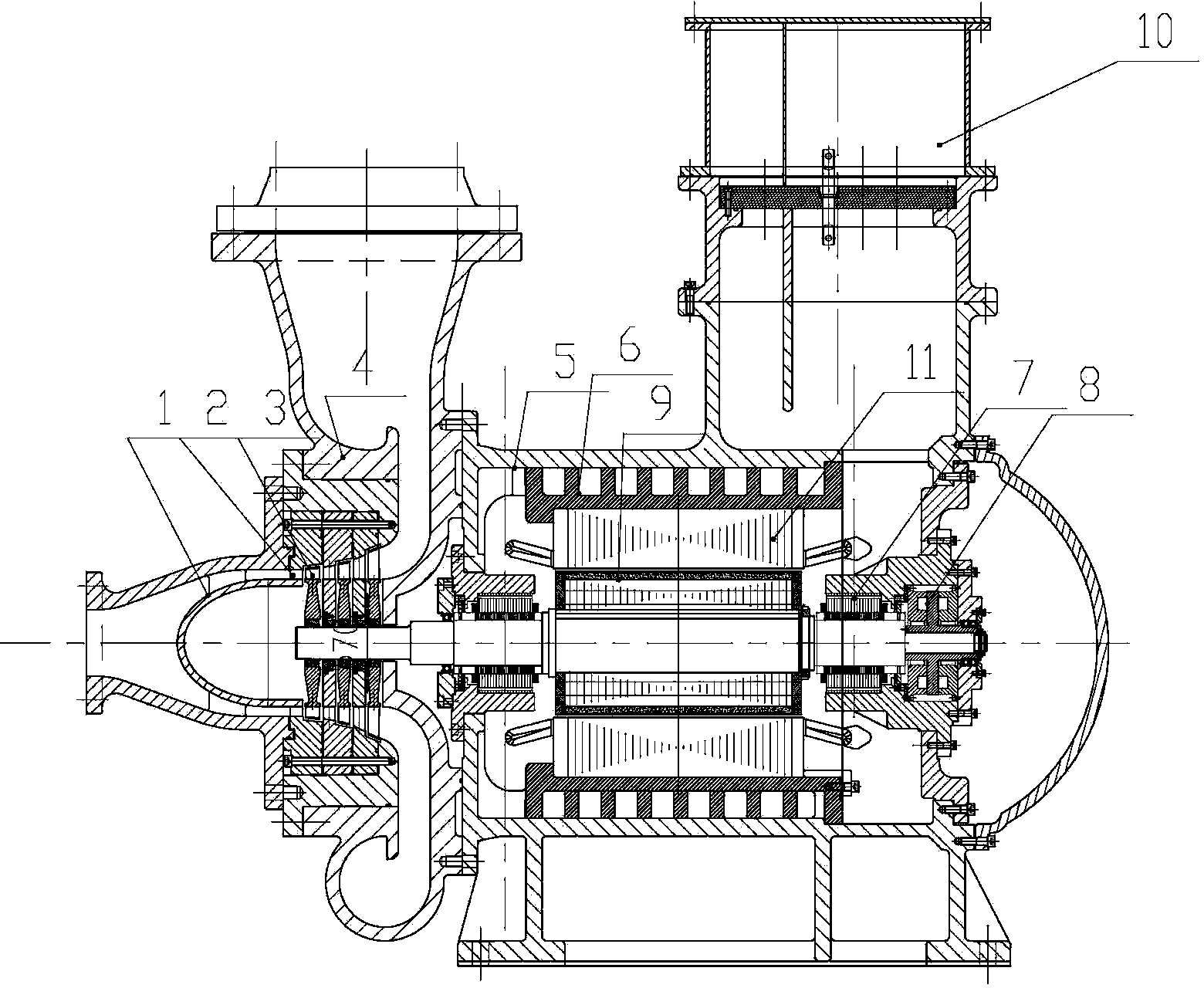

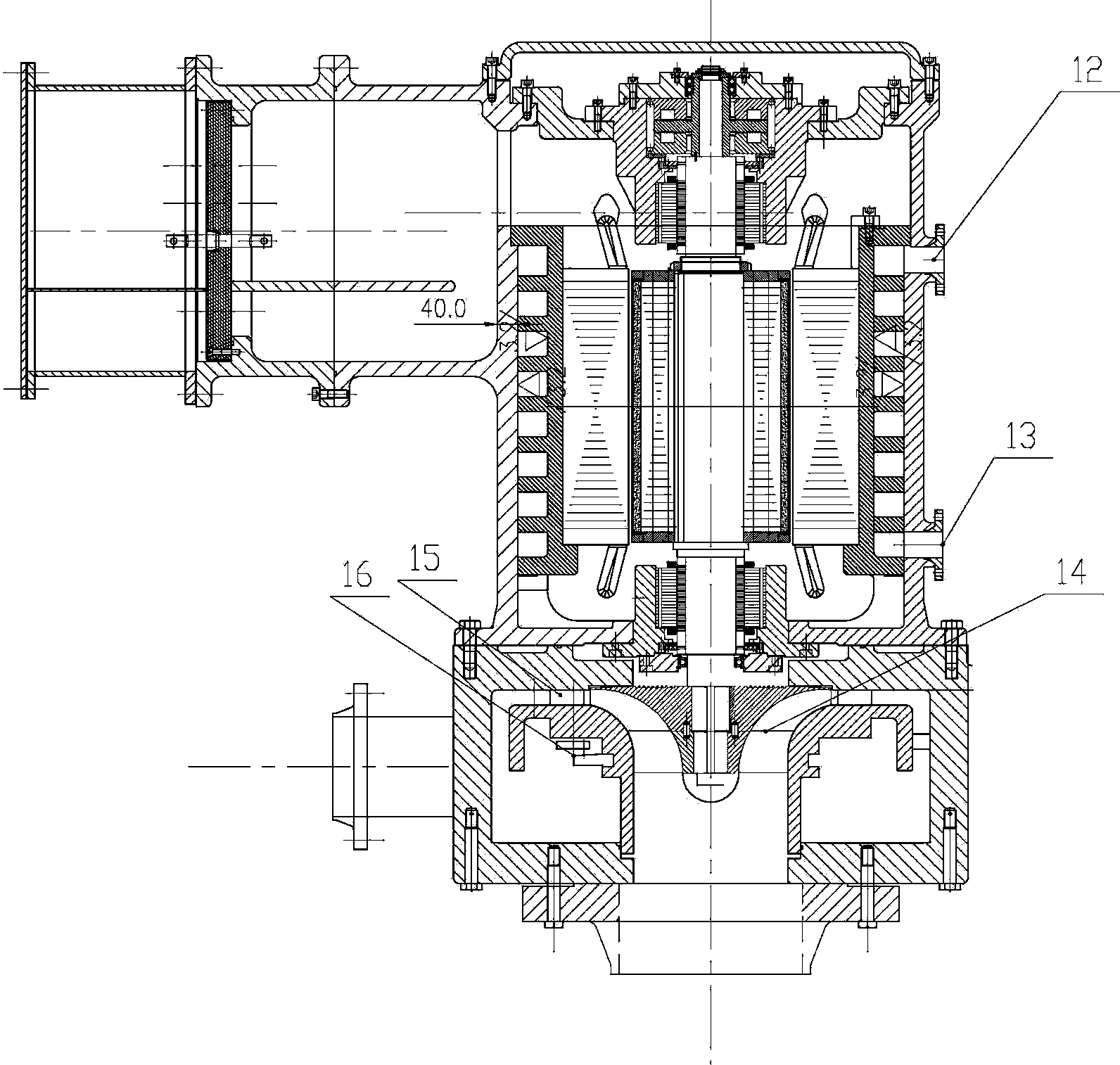

[0025] The integrated turbine unit based on permanent magnet and magnetic levitation technology involved in the present invention is designed with a turbine and a generator (or motor) on a rotating shaft with the same speed.

[0026] 1. When the turbine is an expander:

[0027] An integrated turbomachine consists of a turbine and a generator on the same shaft. One end of the rotating shaft is placed in the turbine, and the rotor blade 3 and the stator blade 2 are arranged outside the shaft, and the turbine volute 4 is arranged outside the rotor blade 3 and the stator blade 2; Set the exhaust port at the end. The other end of the rotating shaft is placed in the generator, the generator rotor 9 is arranged outside the shaft, and the generator stator iron core and winding 11 are arranged outside the generator rotor 9; the tail end of the shaft is arranged in turn with a ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com