Hanging flexible connection of precast concrete infill wall

A technology of prefabricated concrete and flexible connection, which is applied in the direction of walls, building components, and earthquake resistance, and can solve problems such as affecting post-earthquake repair work, design blindness, and heavy on-site workload, so as to enhance horizontal and out-of-plane rigidity, reduce On-site construction workload and the effect of preventing out-of-plane collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

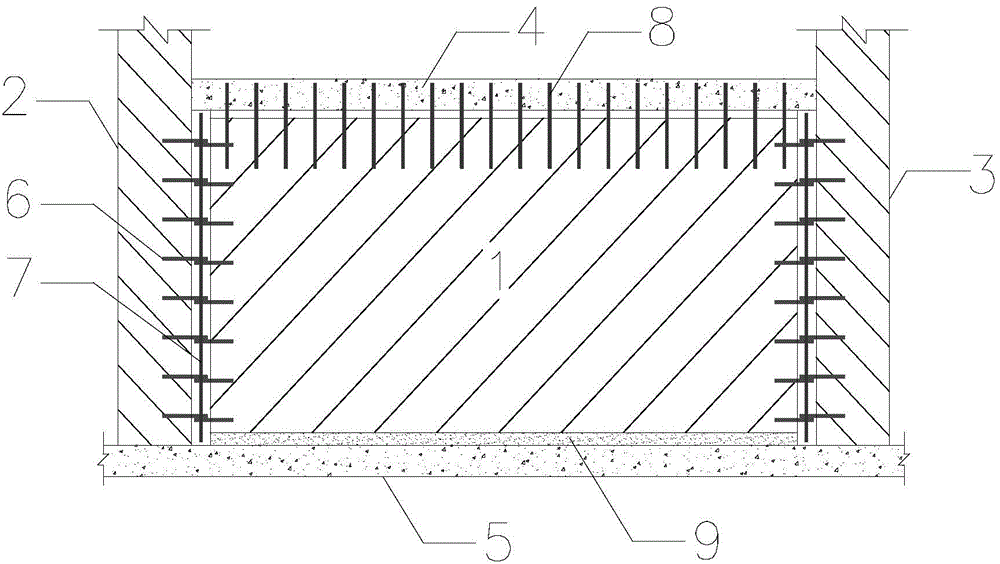

[0019] Such as figure 1 Shown: A precast concrete infill wall suspension type flexible connection, including precast concrete infill wall 1, frame columns / shear walls on both sides of infill wall 2, 3, upper beam / slab on top of infill wall 4, infill wall bottom Lower beam / slab 5;

[0020] The two sides of the precast concrete filled wall are provided with flexible pull rings 6, and the top is provided with reserved ribs 8, and the frame columns / shear walls 2 and 3 on both sides of the described filled wall are provided with flexible pull rings 6 on the side of the precast concrete filled wall 1. Pull ring 6, the upper beam / slab 4 at the top of the filling wall adopts full cast-in-place, laminated cast-in-place or full prefabricated forms, the latter two forms preset grouting holes at the corresponding positions of the reserved ribs 8, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com