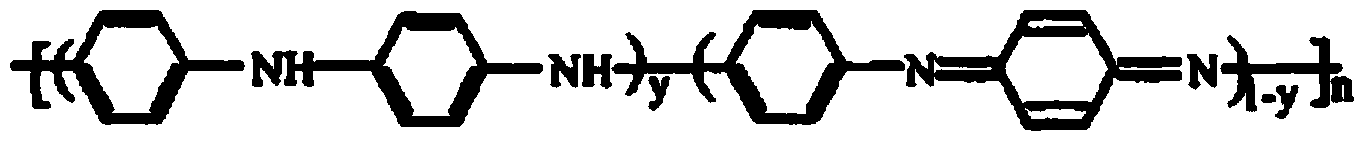

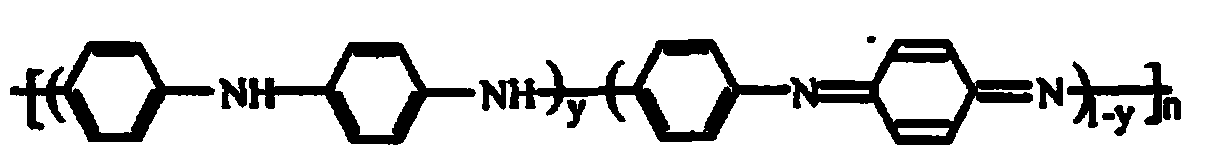

Polyaniline/polyacrylonitrile elastic composite conductive fiber and preparation method thereof

A polyacrylonitrile, composite conductive technology, applied in conductive/antistatic filament manufacturing, fiber processing, spinning solution preparation, etc., can solve problems such as poor applicability and inability to meet industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Weigh 20 grams of polyaniline dodecylbenzenesulfonate and add it to 180 grams of chloroform, and stir at 40°C for 6 hours to obtain solution A;

[0031] Then, 180 g of polyacrylonitrile was added into 600 g of dimethyl sulfoxide, and stirred at 60° C. for 10 hours to obtain solution B. Mix solution A and solution B, stir at 50° C. for 6 hours to make them evenly mixed, and obtain a blended spinning solution.

[0032] The wet spinning technology route is adopted, and conventional wet forming equipment is used. After the above spinning slurry is filtered and metered, it is extruded into the coagulation bath through the spinneret hole. The coagulation bath is an aqueous solution of dimethyl sulfoxide, and the temperature of the coagulation bath is At 20°C, the concentration of dimethyl sulfoxide is 50%, and a certain amount of dodecylbenzenesulfonic acid is added to make the pH value of the coagulation bath 3. After the high polymer is solidified, it passes through guide ...

Embodiment 2

[0034] Example 1 was repeated with the following differences: 15 grams of polyaniline camphorsulfonate was weighed and dissolved with 135 grams of xylene; 135 grams of polyacrylonitrile was dissolved with 500 grams of dimethyl sulfoxide. The doping agent of the fiber is camphorsulfonic acid, the blending solvent is xylene / dimethyl sulfoxide, and the coagulation bath is 50% dimethyl sulfoxide aqueous solution. The electrical conductivity of the fiber is 0.68S / cm, and the strength is 1.76CN / dtex.

Embodiment 3

[0036] Repeat Example 1, with the following differences: 10 grams of dodecylbenzenesulfonate of polyaniline are dissolved with 90 grams of chloroform; 190 grams of polyacrylonitrile are dissolved with 680 grams of dimethylsulfoxide . The dopant of the fiber is dodecylbenzenesulfonic acid, the blending solvent is chloroform / dimethyl sulfoxide, and the coagulation bath is 50% aqueous solution of dimethyl sulfoxide. The electrical conductivity of the fiber is 7.3×10-3S / cm, and the strength is 2.90CN / dtex.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com