Heat-conducting hot melt adhesive and preparation method thereof

A hot melt adhesive, particle size technology, applied in the direction of adhesives, adhesive additives, polymer adhesive additives, etc., can solve the problems of long operation time, limited protection ability, affecting production efficiency, etc., and achieve high-efficiency thermal conductivity, The effect of good refractive index and strong ability to absorb axial heat source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

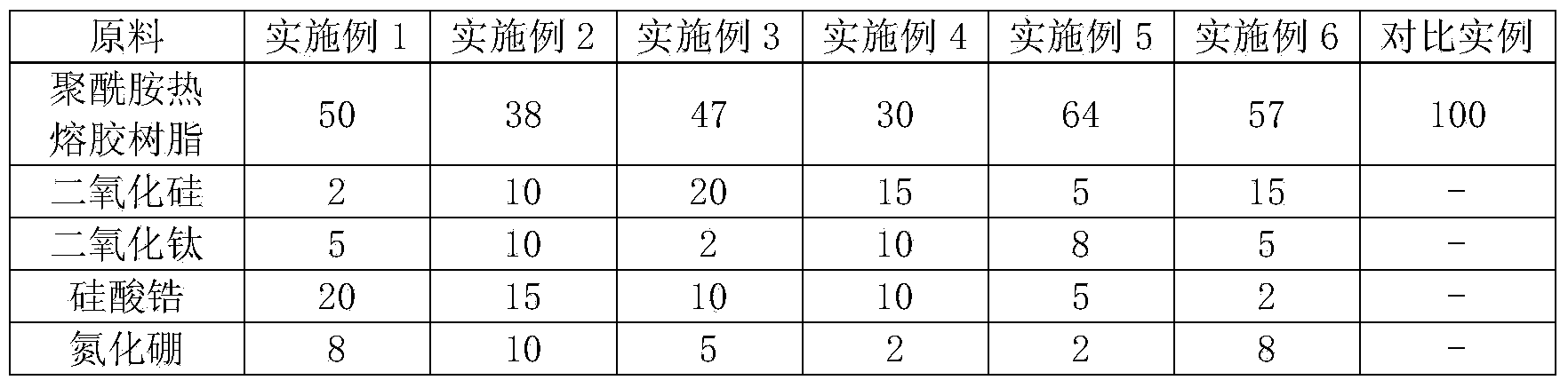

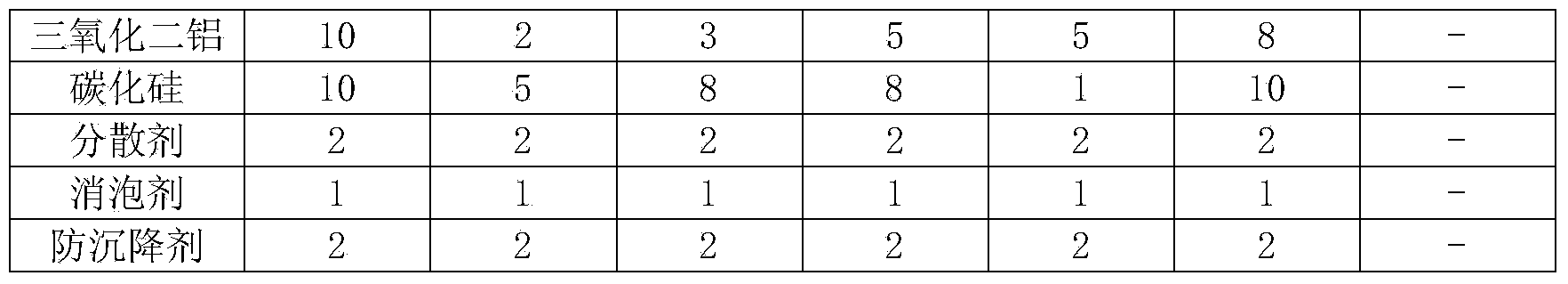

[0019] First, heat the synthetic resin to generate a hot-melt adhesive resin; the preparation of the hot-melt adhesive resin is specifically: the synthetic resin is made by the high-temperature reaction of a diamine and a dibasic acid through a traditional process, and is heated to melt to synthesize a hot-melt adhesive resin , in the final stage of hot melt adhesive resin synthesis, the temperature is 240 ° C, and the following heat-conducting components are added while stirring: add silicon dioxide, titanium dioxide, zirconium silicate, boron nitride, and three Aluminum oxide, silicon carbide, dispersant, defoamer and anti-settling agent; after the feeding is completed, start the dispersion and stirring, and vacuumize, disperse for 2 hours, after the dispersion is uniform, the normal production of granulation and discharge, the finished product .

[0020] Table 1

[0021]

[0022]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com