Calendering base material for bank double-interface intelligent card and preparation method thereof

A dual-interface smart card and calendering base material technology, which is applied in the field of smart card calendering base material, can solve problems such as unsuitable, unsatisfactory, and single-purpose, and achieve the effects of prolonging service life, improving card base strength, and increasing coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

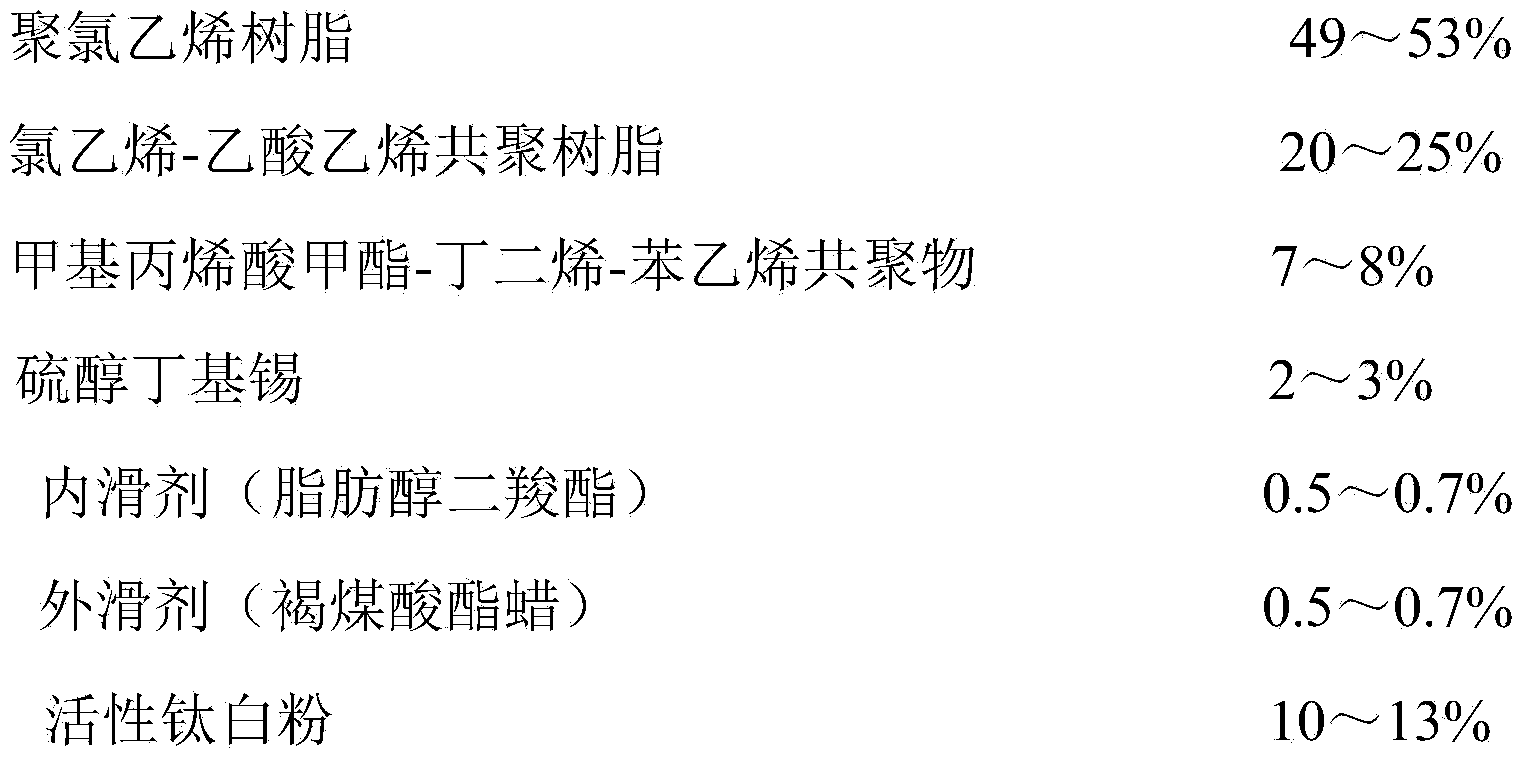

[0024] Components and weight percent content are as follows:

[0025]

[0026] Preparation:

[0027] The raw materials are respectively metered into the high-speed kneader and kneaded at a temperature of 110°C. The high-speed kneader rotates at a speed of 600 rpm, then cooled and stirred at a temperature of 50°C, and extruded by a planetary extruder at a temperature of 190°C. ℃, the extrusion temperature of the single-screw extruder is 140°C, and finally the five-roll calender is used for calendering, and the processing temperatures are: 190°C for No. ℃.

[0028] The product is tested using GB and DIN standards, and the results are shown in attached tables 1, 2 and 3:

[0029] Table 1

[0030]

[0031] Front and back technical parameters of dual-interface (contact and contactless) smart cards for banks

[0032]

[0033] Table 2

[0034] project

indicators

Tensile strength Mpa≥

38

Tensile impact strength KJ / m2≥

550

Vicat ...

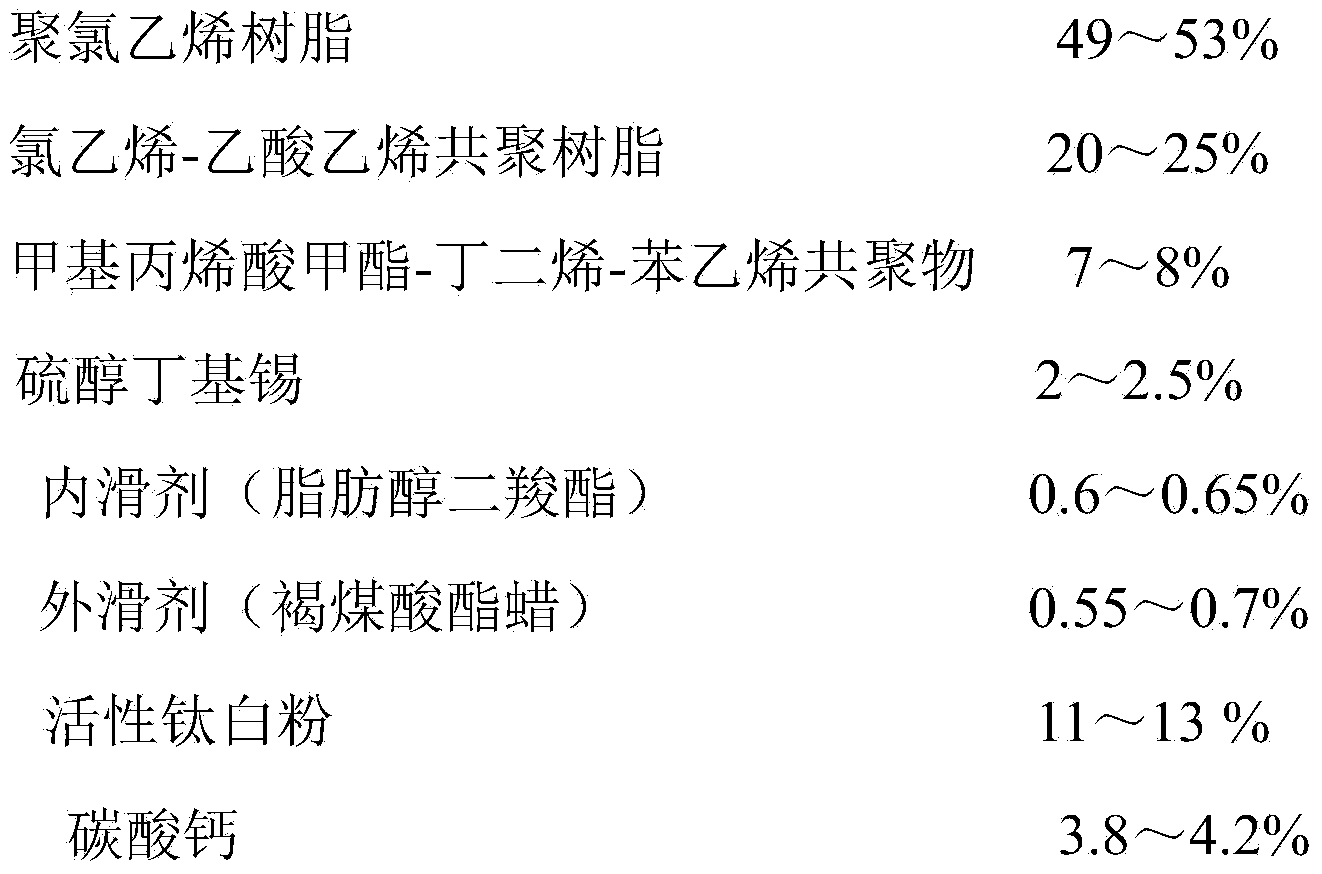

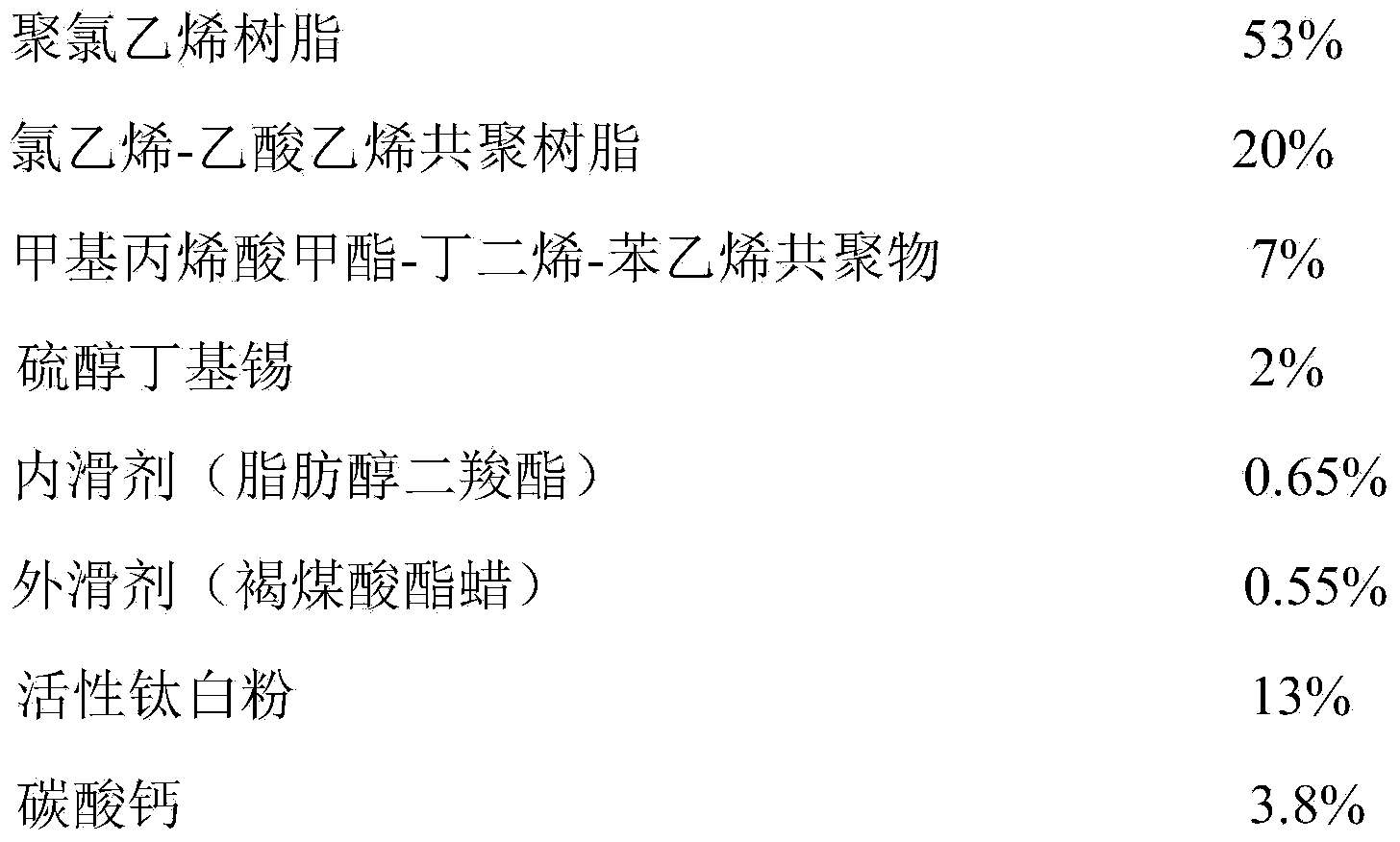

Embodiment 2

[0038]

[0039]

[0040] Preparation:

[0041] The raw materials are respectively metered into the high-speed kneader and kneaded at a temperature of 115°C. The high-speed kneader rotates at a speed of 700 rpm, then cooled and stirred at a temperature of 55°C, and extruded by a planetary extruder at a temperature of 195°C. ℃, the extrusion temperature of the single-screw extruder is 145°C, and finally it is calendered by a five-roller calender. ℃.

[0042] Using GB and DIN standards to test the product, the results are as follows:

[0043] Shanghai Dakai Plastic Co., Ltd.

[0044] Product inspection report

[0045] No.QF / 0819

[0046] Batch number: 20130920 Item number: 2-106

[0047] Specification: 0.15 / 530x630 Variety: Calendered base material for bank dual-interface (contact and non-contact) smart cards

[0048] Color: milky white Production date: 2013.9.11

[0049] serial number

[0050] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com