TPO waterproof coiled material and production process thereof

A waterproof membrane and production process technology, applied in the field of TPO waterproof membrane and its production process, can solve the problems of asphalt waterproof materials such as high-temperature flow, low-temperature brittleness, and cumbersome construction process, and achieve firm and reliable welding strength, good extensibility, Strong weldability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A TPO waterproof membrane, calculated in parts by weight, including: 50 parts of thermoplastic polyolefin (POE), 25 parts of low-density polyethylene (LDPE), 25 parts of light carbonic acid treated with silane coupling agent Calcium, 0.2 part of UV-9 ultraviolet absorber, 0.1 part of 1010 primary antioxidant, 0.2 part of 168 secondary antioxidant, 0.3 part of stearic acid and 3.0 part of titanium dioxide.

[0021] The steps of a production process of a TPO waterproof coiled material are as follows:

[0022] a. Kneading: 25 parts of low-density polyethylene (LDPE), 25 parts of light calcium carbonate treated with silane coupling agent, 0.2 part of UV-9 ultraviolet absorber, 0.1 part of 1010 primary antioxidant, 0.2 Add 168 parts of auxiliary antioxidant into the high-speed kneader for kneading. Before adding, ensure that the temperature in the kneader is kept at 90±5°C, and the kneading time is 5 minutes. The above materials are evenly dispersed;

[0023] Add 0.2~0.5 p...

Embodiment 2

[0028] A kind of TPO waterproof roll material, compare with embodiment 1, under the situation that other conditions are completely identical with embodiment 1, only change the number of parts of low-density polyethylene (LDPE), take 30 parts of low-density polyethylene in embodiment 2 , the parts by weight of other components do not change, and are produced according to the production process of the TPO waterproof membrane described in Example 1 to prepare the TPO waterproof membrane.

Embodiment 3

[0030] A kind of TPO waterproof roll material, compare with embodiment 1, under the situation that other conditions are completely identical with embodiment 1, only change the number of parts of low-density polyethylene (LDPE), take 35 parts of low-density polyethylene in embodiment 3 , the parts by weight of other components do not change, and are produced according to the production process of the TPO waterproof membrane described in Example 1 to prepare the TPO waterproof membrane.

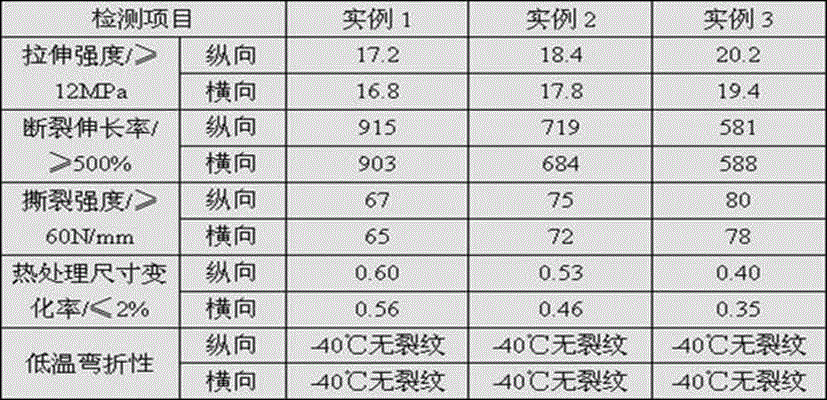

[0031] The performance of the TPO waterproof membrane prepared according to the above three examples is tested. The data obtained from the test shows that the content of low-density polyethylene (LDPE) plays a key role in the performance of the TPO waterproof membrane. The test results are shown in Table 1:

[0032] Table 1:

[0033]

[0034] It can be seen from Table 1 that the content of low-density polyethylene (LDPE) has the following effects on the prepared TPO waterproof membrane: ten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com