Iron core feed adjustable stopper

A feed adjustment and stopper technology, which is applied to the attachments of shearing machines, shearing devices, metal processing equipment, etc., can solve the problems of swinging silicon steel sheets, uneven width of silicon steel sheets, etc., so as to improve processing accuracy and solve width problems. Inequality, the effect of eliminating process defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

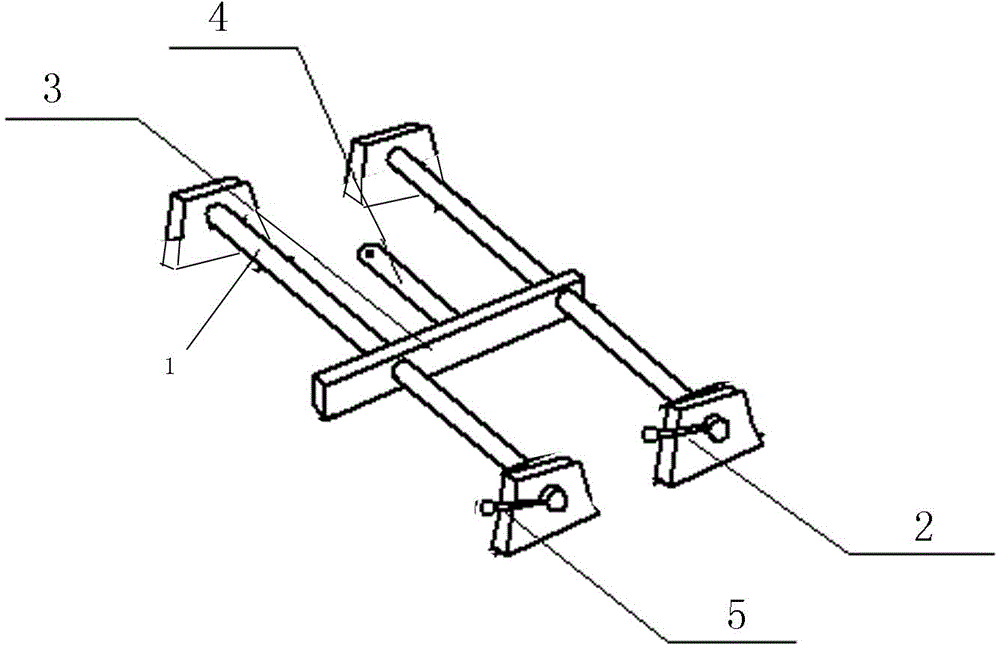

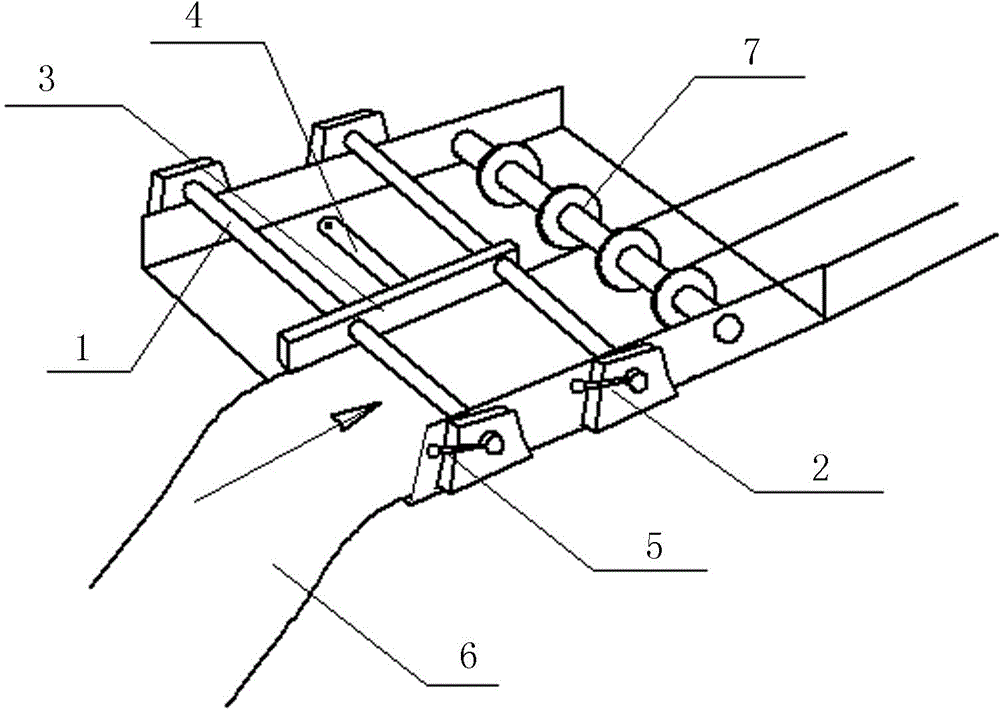

[0017] Such as Figure 1-2 As shown, there are two adjusting screws 1, and the two ends of the two adjusting screws 1 are connected to the end fixing plate 2 by screws, and the vertical distance between the bottom edge of the end fixing plate 2 and the adjusting screw 1 is greater than that of the end fixing plate 2 The vertical distance of the top edge distance adjustment screw 1. The adjusting screw 1 is equipped with a stopper 3, which is flexibly connected with the adjusting screw 1, the stopper 3 is arranged between the end fixing plates, and the vertical distance between the bottom edge of the stopper 3 and the adjusting screw is greater than that of the stopper 3 The vertical distance of the top edge distance adjustment screw rod, the below of stop chi 3 is provided with standard chi 4. The end of the adjusting screw is provided with an adjusting knob 5 . The axial length of the adjusting screw matches the width of the rolling shear 7 .

[0018] When in use, install ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com