Breathable itching-relieving antisepsis scar treating paster and preparation method thereof

A technology for treating plasters and scars. It is applied in the direction of medical formulas, medical preparations containing active ingredients, and devices that make medicines into special physical or ingestible forms. It can solve the problems of poor air permeability, easy bacterial growth, and poor drainage effect. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The present invention also provides a preparation method of an air-permeable anti-itch antibacterial scar treatment plaster, comprising the following steps:

[0025] a. Ingredients: Prepare raw materials according to the following weight ratio: silicone 97.9%, menthol 1%, borneol 1%, heparin sodium 0.05%, nano silver 0.05%; add nano silver to N,N-dimethylformamide DMF , and ultrasonically disperse; then dissolve silicone, menthol, borneol, and heparin sodium; add a porogen with a particle size of 50-75 μm to the aforementioned solution, so that the final concentration of the porogen is 500g / L; Stir for 15 to 20 minutes;

[0026] b. Passing through the mold: degas the suspension obtained in step a for 20-30 minutes at a vacuum of 0.6-0.8 MPa; pour the defoamed suspension into the mold, cast evenly, pass the amount of the suspension Control the thickness of the liquid embryonic membrane to be 1.5mm;

[0027] c. Molding: Place the mold containing the liquid embryonic mem...

Embodiment 1

[0036] Embodiment 1 The preparation of breathable antipruritic antibacterial scar treatment patch

[0037] Add nano-silver antibacterial powder into N,N-dimethylformamide (DMF), ultrasonically disperse for 10-15 minutes, power 300w, and prepare a solution with a final concentration of nano-silver of 0.05%. Then silicone granules, menthol, borneol, and heparin sodium granules were dissolved therein so that the final concentrations were 97.9%, 1.0%, 1.0%, and 0.05%, respectively. Then sieve the porogen pulverized by the pulverizer, and pour the particles with a particle size between 50 and 75 μm into the prepared solution so that the concentration of the porogen is 500g / L; In a mixer with a thermometer, mechanically stir at room temperature for 20 min. After degassing for 30 minutes at a vacuum degree of 0.6-0.8 MPa, it is poured into a polytetrafluoroethylene mold, cast evenly, and the thickness of the liquid embryo film is controlled to be 1.5 mm by the amount of the suspensi...

Embodiment 2

[0038] Example 2 Performance Test of Breathable Antipruritic Antibacterial Scar Therapy Patch

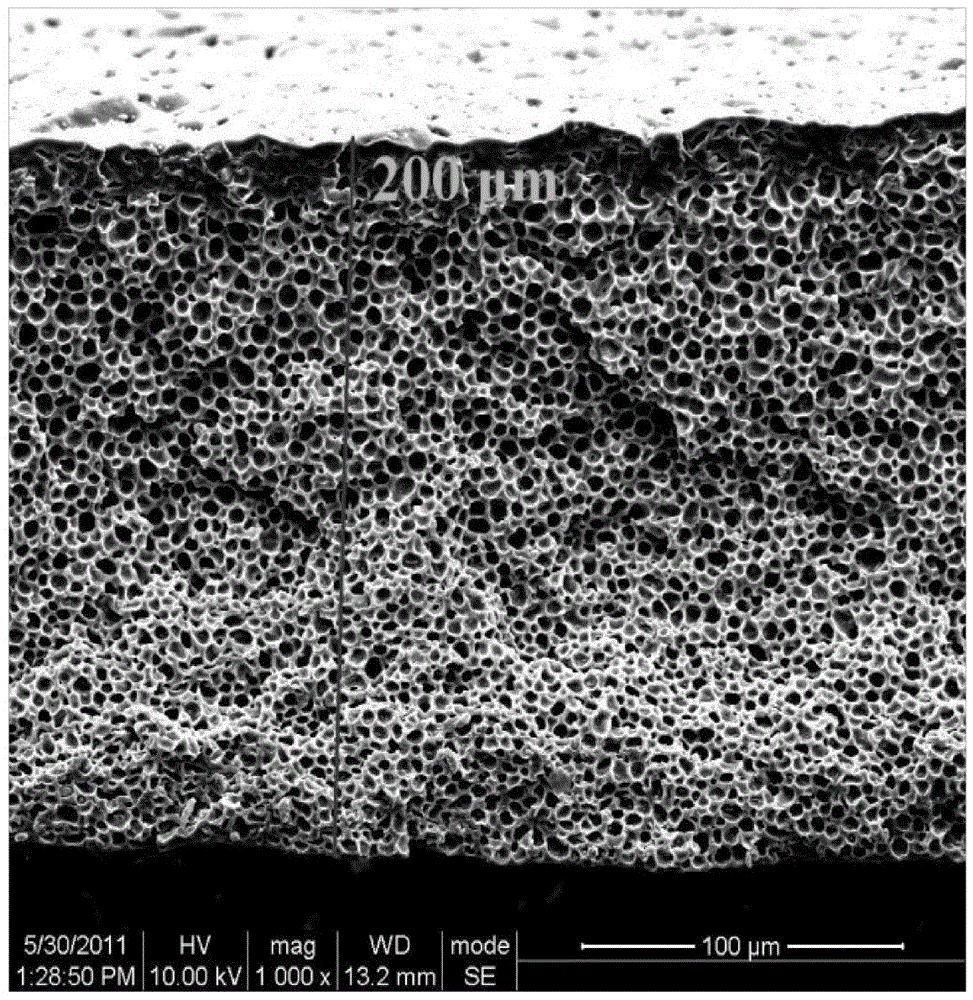

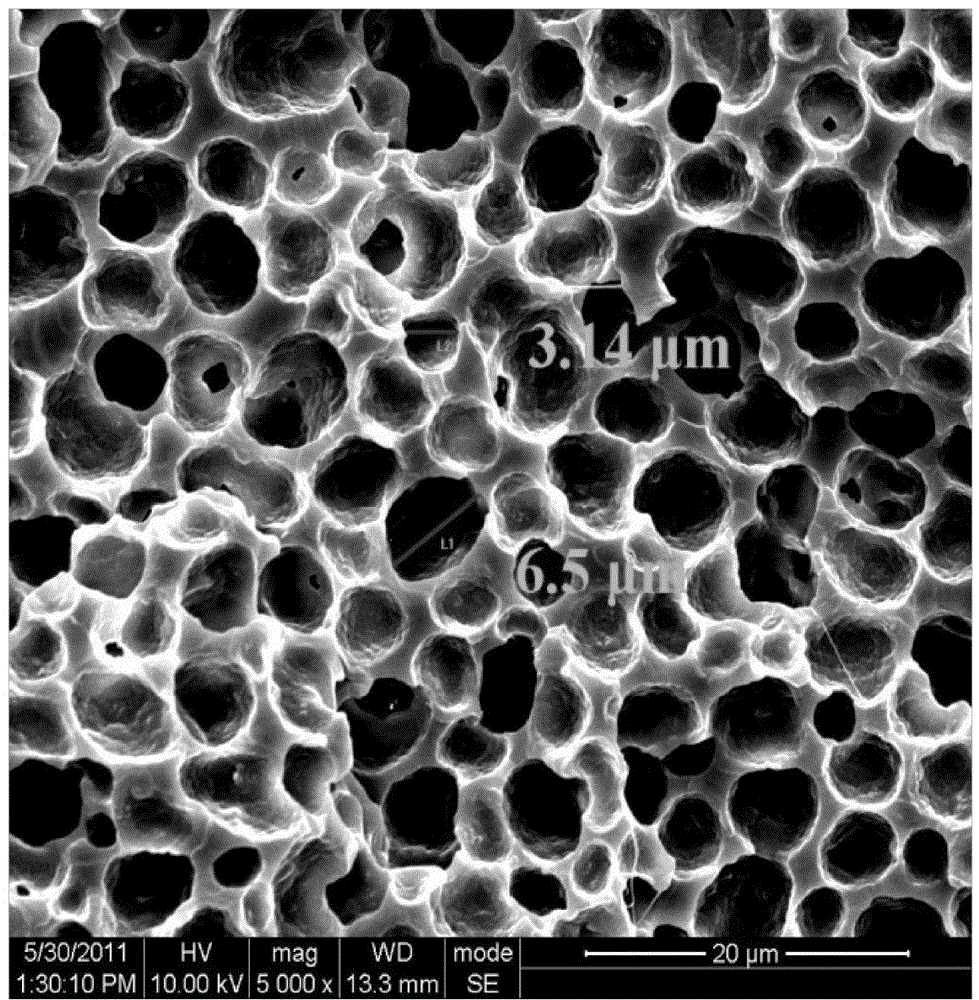

[0039] 1. Use a scanning electron microscope to observe the surface pore structure of the breathable anti-itch antibacterial scar treatment patch: cut the treatment patch into a small circular piece with a diameter of 3 cm, wrap it in a gold-palladium mixture in a vacuum environment, and then observe it under a scanning electron microscope. See the results for details figure 1 shown.

[0040] 2. The average pore diameter of the holes on the surface of the air-permeable anti-itch antibacterial scar treatment plaster is calculated by software from the scanning electron microscope observation results, and the porosity is 20,000-30,000 / mm2. See the results for details figure 2 .

[0041] 3. Measurement of air permeability: Cut the treatment patch into a disc shape with a diameter of 35mm, cover the opening of a cylindrical cup with a diameter of 34mm filled with 10mL ultrapure water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com