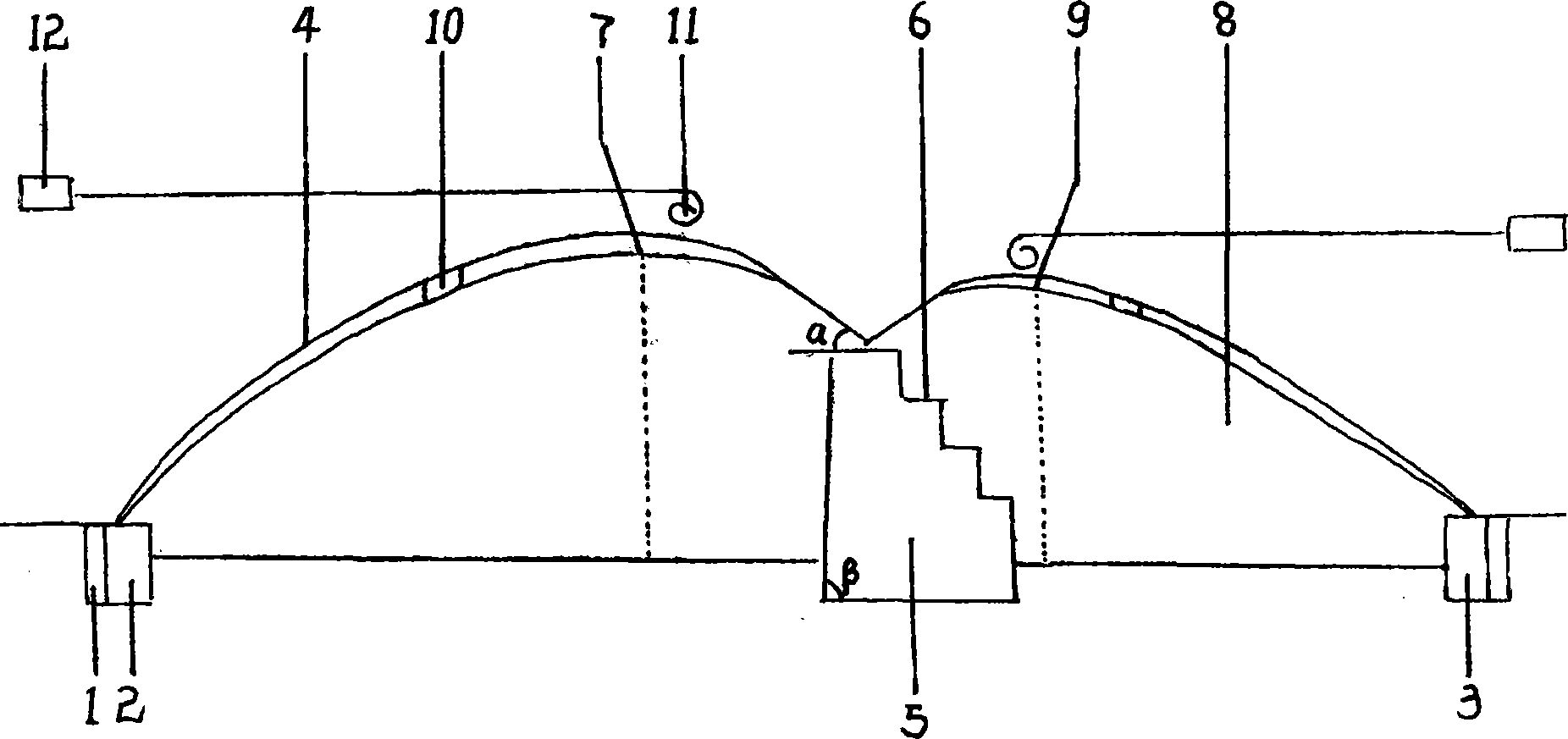

Greenhouse with sunny and shaded surfaces

A greenhouse and two-sided technology, which is applied in the field of greenhouses planted on both sides of the yin and yang, can solve the problems that the shady side is not fully utilized, the back wall occupies a large area of land, and is unfavorable for saving land, so as to improve land utilization, effectively use heat energy, and save land. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] A planting shed with both yin and yang sides, comprising a cold-proof layer (1), a front wall (2), a rear wall (3), a daylighting roof (4), an earth wall (5), a planting bed (6), and a front shed ridge (7) , rear shed (8), rear shed ridge (9), air vent (10), roller shutter (11), motor (12), described planting shed is oriented east-west, and described front wall (2) front, The rear part of the back wall (3) is a cold-proof layer (1) composed of plastic paper wrapped benzene boards. The front wall (2) and the back wall (3) are composed of a 10 cm thick base layer and a 50 cm high 240 brick wall. (2), the top of the back wall (3) and the top of the cold-proof layer (1) are flush with the ground plane, and an arc-shaped daylighting roof (4) is arranged between the top of the front wall (2) and the top of the earth wall (5). The wall (5) is 3.5 meters high, and a stepped planting bed (6) is arranged on the side facing the shade. The inside elevation angle α between the top o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com