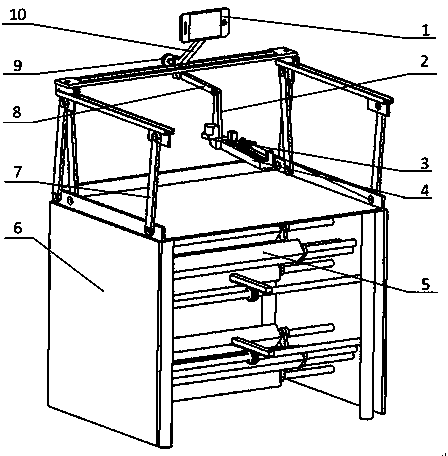

Novel DIY innovating and manufacturing platform

A production platform and a new type of technology, applied in the direction of educational appliances, instruments, teaching aids, etc., can solve the problems of poor interaction effect, poor practicability, poor classroom role positioning, etc., to achieve perfect functions, strong practicability, rich expressions and body movements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings, so that those skilled in the art can better understand the present invention. It should be noted that in the following description, when detailed descriptions of known functions and designs may dilute the main content of the present invention, these descriptions will be omitted here.

[0023] Working process of the present invention is as follows:

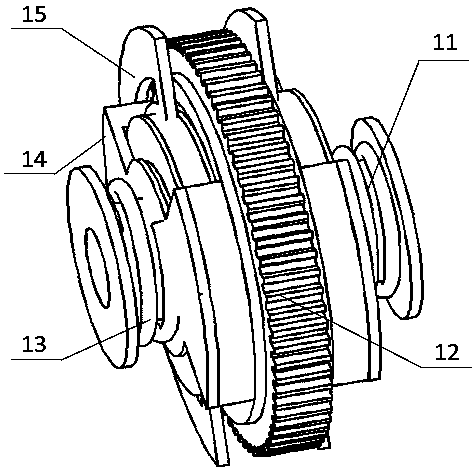

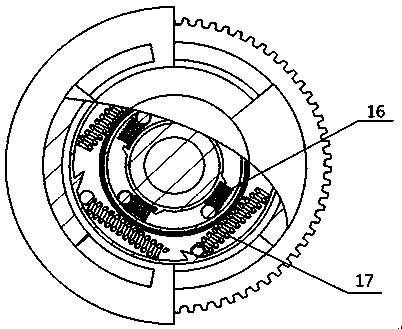

[0024] When the hinge gear (12) in the static friction self-locking gear does not rotate, the friction disc (14) is pressed by the thrust spring 2 (13), and the friction disc (14) and the hinge gear (12) squeeze each other. The greater the positive pressure, the greater the maximum static friction. When the torque loaded on the hinge gear is not large enough, the hinge is in a self-locking state. Due to the manual application of force, a large torque is loaded on the hinge gear (12), and the gear overcomes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com