Setting method of emulsion concentration in ultra-thin strip rolling of five-stand cold tandem mill

A five-stand cold tandem rolling and emulsion technology, which is applied in the field of metallurgical cold rolling, can solve the problems of instable rolling speed of the unit, poor surface quality of strip steel, and low rolling speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

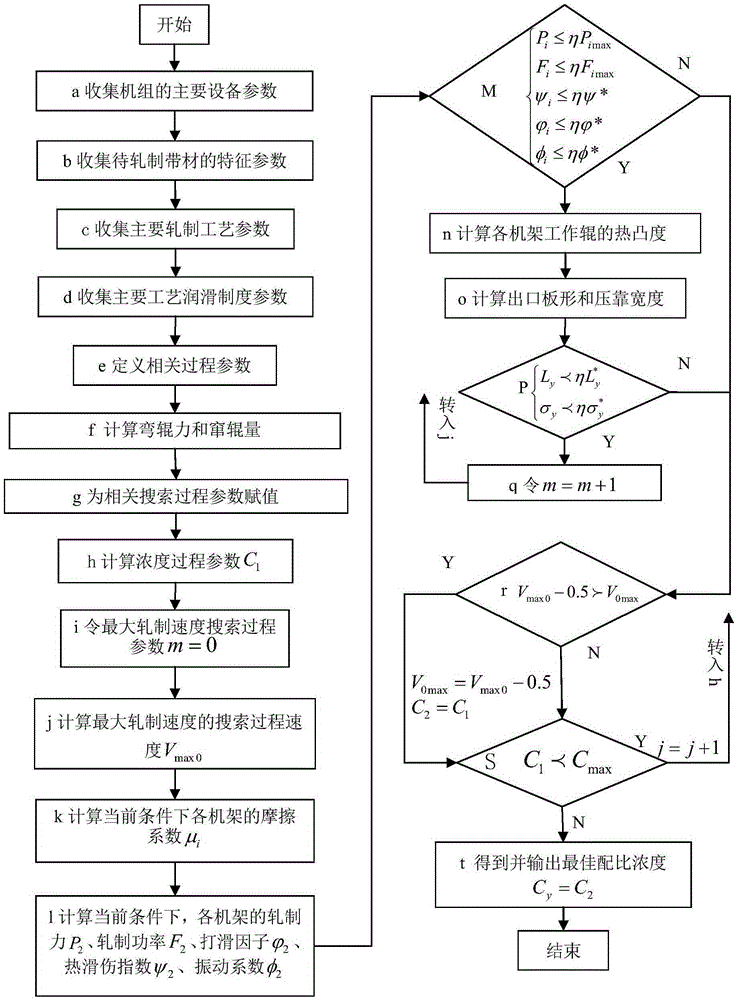

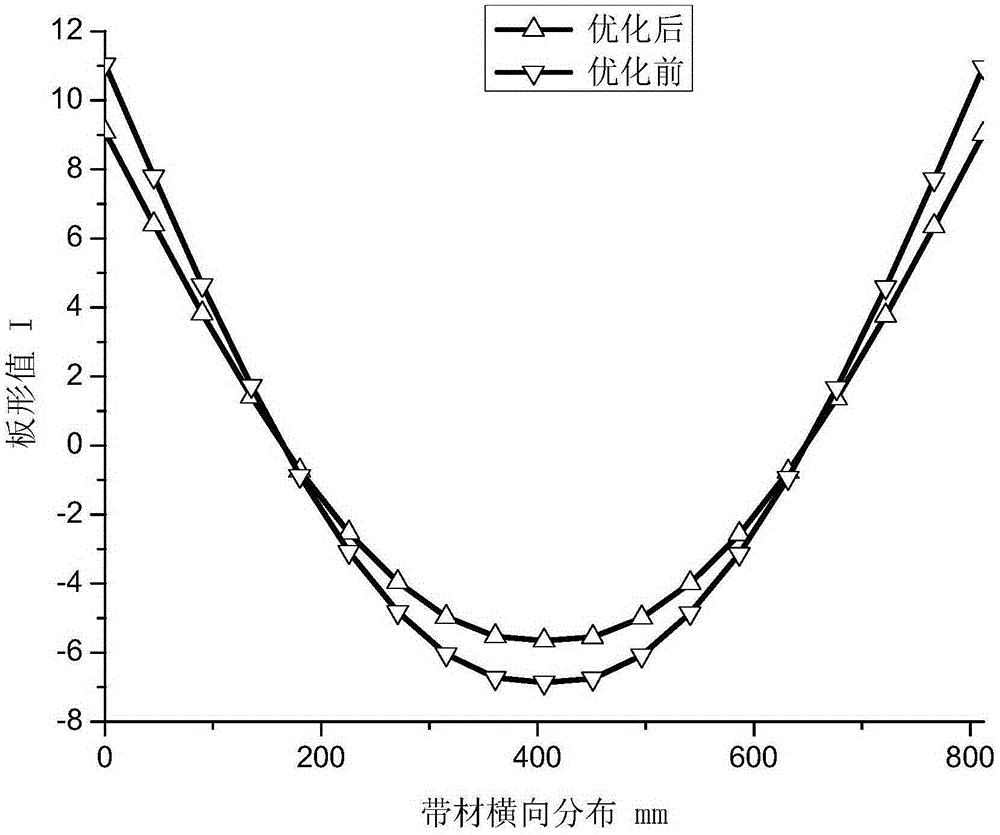

[0038] exist figure 1 In the overall calculation flow chart of the method for setting the emulsion concentration in the ultra-thin strip rolling of the five-stand cold tandem mill as shown, first, in step 1, collect the main equipment and parameters of the five-stand cold tandem mill Process parameters, 1-5 stand rolling mill allowable maximum rolling pressure setting value P imax =(1800t, 1800t, 1800t, 1800t, 1800t) i=1, 2,...5, 1-5 stand rolling mill allowable maximum rolling power setting value F imax =(2680kw, 4000kw, 4000kw, 4000kw, 4000kw), 1-5# frame middle roller allowable maximum displacement δ imax =80mm, 1-5# frame work roll maximum positive roll bending force Maximum negative bending force of working rolls in 1-5# frame The maximum positive bending force of the middle roll of 1-5# frame The maximum negative bending force of the middle roll of 1-5# frame The maximum pressing length allowed by the end frame The maximum plate shape value allowed at the outl...

Embodiment 2

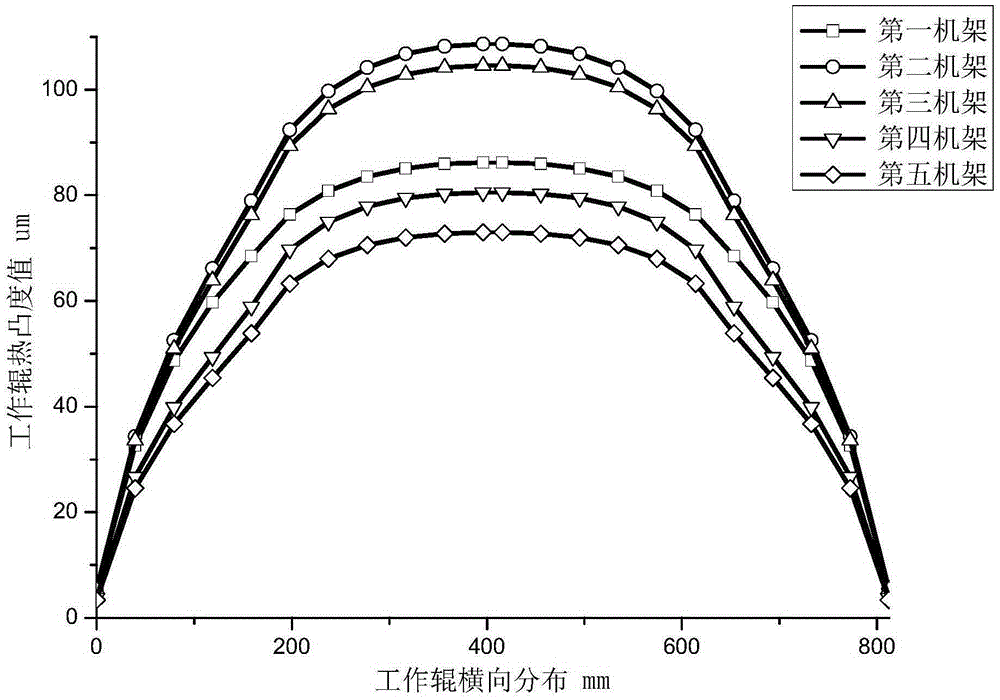

[0062] First, in step 1, collect the main equipment and process parameters of the five-stand cold tandem rolling mill, the allowable maximum rolling pressure setting value P of the 1-5 stand rolling mill imax =(1800t, 1800t, 1800t, 1800t, 1800t) i=1, 2,...5, 1-5 stand rolling mill allowable maximum rolling power setting value F imax =(2680kw, 4000kw, 4000kw, 4000kw, 4000kw), 1-5# frame middle roller allowable maximum displacement δ imax =80mm, 1-5# frame work roll maximum positive roll bending force Maximum negative bending force of working rolls in 1-5# frame The maximum positive bending force of the middle roll of 1-5# frame The maximum negative bending force of the middle roll of 1-5# frame The maximum pressing length allowed by the end frame The maximum plate shape value allowed at the outlet of the last frame 1-5# work roll diameter D iw ={476.84,480.86,463.06,399.33,406.86}mm, 4-5# frame middle roller diameter D im ={533.26,529.82,513.45,510.46,508.92}mm, 1-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com