Pipeline leakage acoustic emission signal processing method based on compressed sensing and HHT in mask signal method

A technology of acoustic emission signal and mask signal, which is applied in the pipeline system, mechanical equipment, gas/liquid distribution and storage, etc. It can solve the problem that the signal amplitude-frequency ratio does not meet the requirements, the ideal detection effect cannot be achieved, and the mode mixing, etc. problem, to achieve the effect of reducing data acquisition cost, suppressing modal aliasing, and facilitating feature extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

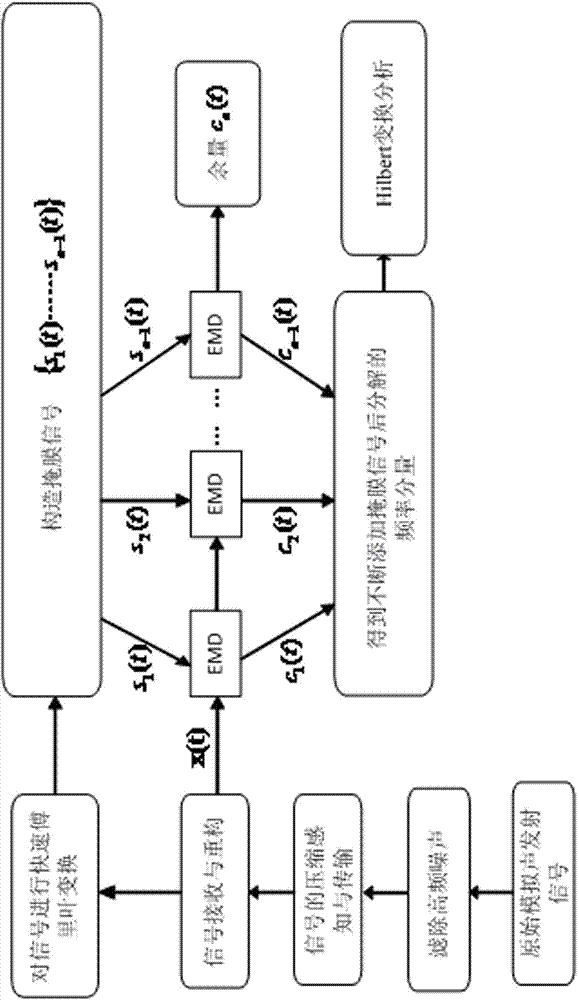

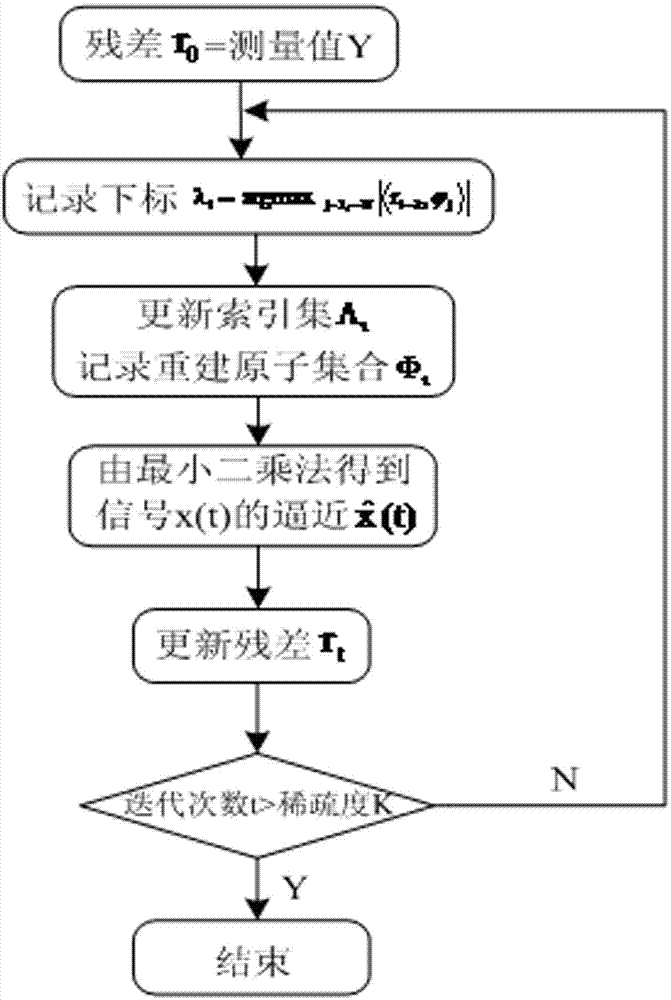

[0029] The purpose of the present invention is to solve the problem of ultra-high frequency and large data transmission and storage in the acoustic emission signal detection technology, and obtain accurate decomposition results to provide the possibility for feature extraction, classification and positioning. That is to introduce the compressed sensing theory into the acoustic emission signal detection technology, and then use the EMD decomposition method of adding the mask signal to realize the decomposition of the acoustic emission signal, and perform Hilbert transformation on the components to determine the start and end time of the leakage, compressive sensing theory; and A signal analysis method adding the Hilbert-Huang transform of the masked signal.

[0030] The specific treatment plan is:

[0031] Step 1: Obtain the original acoustic emission signal and filter it. Since the leakage acoustic emission signal has a certain frequency domain, a Butterworth low-pass filter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com