A multi-stage pressure reducing valve

A pressure reducing valve and valve stem technology, which is applied in the field of multi-stage pressure reducing valves, can solve the problems of unbalanced lateral force, poor throttling stability, and damage to valve trims, so as to avoid cavitation and improve service life Long, well-structured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

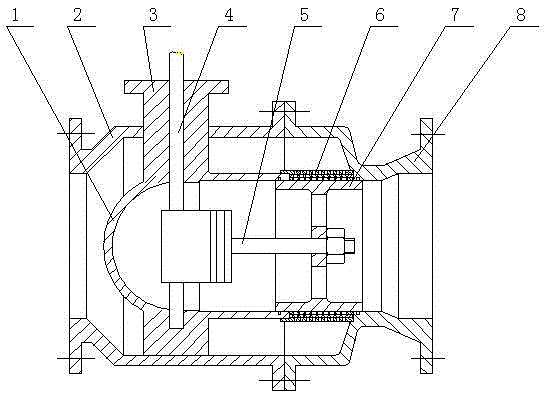

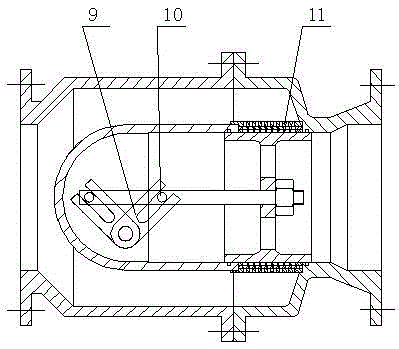

[0014] Such as figure 1 , 2 As shown, a multi-stage pressure reducing valve includes a left valve body 2, a right valve body 8, a valve stem 4, and a guide cylinder 1. The guide cylinder 1 is fixedly connected with the left valve body 2 through a shaft seat 3, and the valve stem 4 Radially through the guide tube 1 is fixed in the shaft seat 3, the valve stem 4 is located in the inner cavity of the guide tube 1 and connected to a shift fork 9, and the port of the guide tube 1 is fixedly connected to a multi-stage sleeve 6, the multi-stage sleeve 6 is provided with a plurality of taper holes 11, and a piston cylinder 7 is arranged in the inner cavity of the multi-stage sleeve 6 and the guide tube 1. The piston tube 7 is located on the same axis as the multi-stage sleeve 6 and the guide tube 1. A piston rod 5 is fixedly connected on the axis position, and a pin shaft 10 is fixedly connected to the front section of the piston rod 5, and the pin shaft 10 is connected with the shif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com