Novel feed water adjusting valve

A water supply control valve, a new technology, applied in the direction of sliding valve, valve details, valve device, etc., can solve the problems of reducing the service life of the control valve, waste of energy, leakage, etc., and achieve the effect of prolonging the service life, reducing noise and preventing scouring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

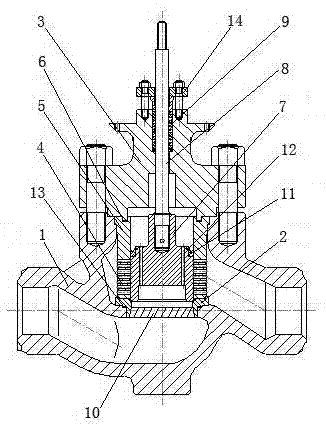

[0014] A new type of water supply regulating valve, comprising a valve body 1, a valve seat 2 is provided in the middle of the valve body 1, a valve cover 3 is installed on the upper end of the valve body 1, and a throttle ring 4 is provided above the valve seat 2, A flow equalizing cover 5 is provided above the throttle ring 4, an annular groove is provided on the upper end surface of the flow equalizing cover 5, and an annular boss located in the annular groove is provided on the lower end surface of the valve cover 3. A bonnet sealing ring 6 is arranged between the groove and the annular boss, and a plurality of through holes are arranged on the side wall of the lower part of the flow equalizing cover 5, and a valve core 7 is arranged in the flow equalizing cover 5, and a balancing valve is provided on the valve core 7. hole, the upper end of the valve core 7 is connected with a valve stem 8, the upper end of the valve stem 8 runs through the valve cover 3, a sealing ring 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com