A method of anti-freezing and drainage for high-altitude severe cold and water-rich tunnels with permanent combination

A technology that combines rich water tunnels with permanent and permanent ones. It is applied in drainage, earthwork drilling, safety devices, etc. It can solve problems such as unsmooth drainage systems and frost heave, and eliminate problems that cannot be closed in time, ensure operational safety, and speed up water The effect of velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

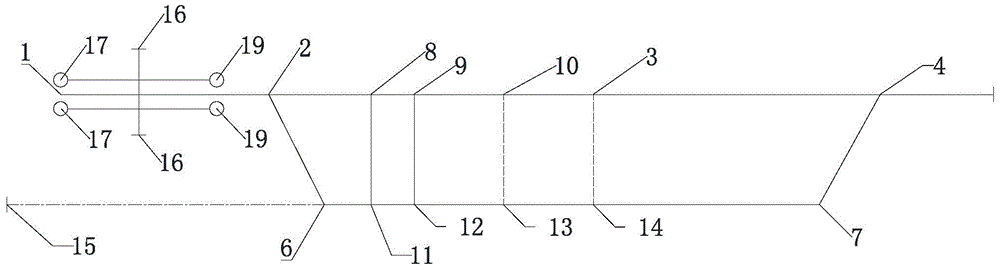

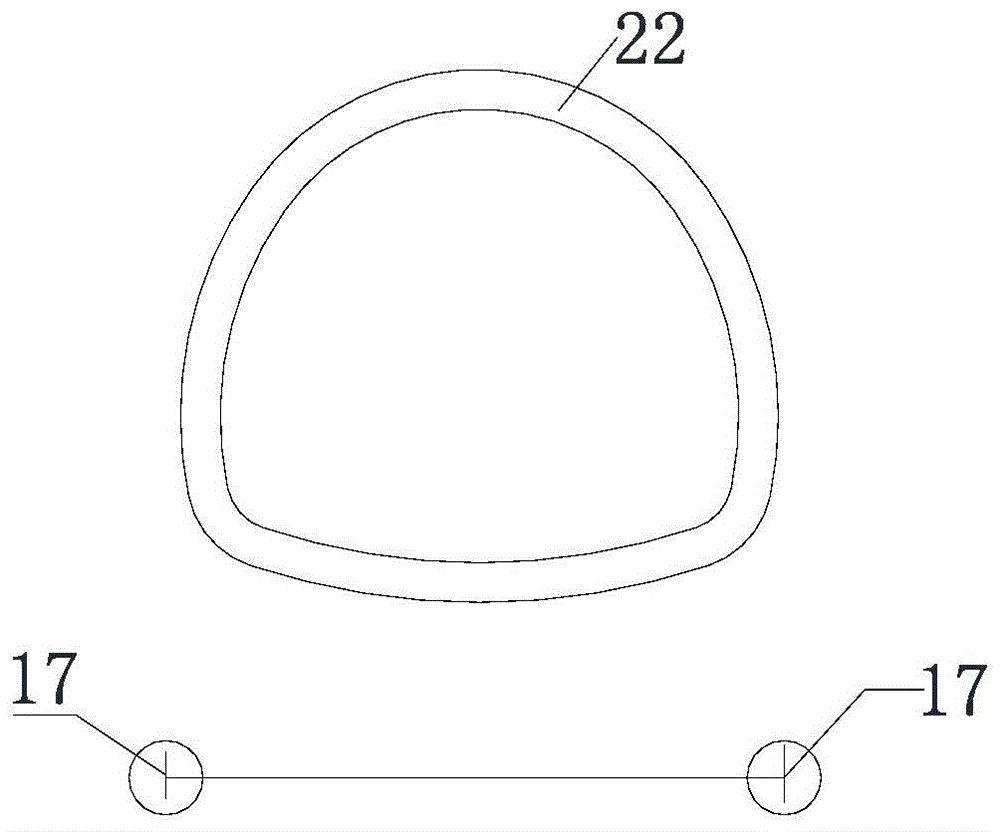

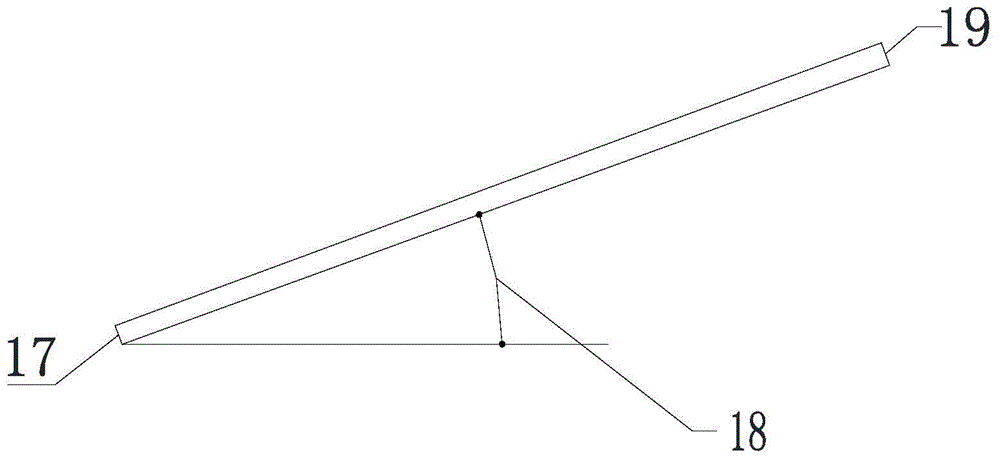

[0035] See Figure 1 to Figure 6 As shown, the present invention is a high-altitude cold-water-rich tunnel permanently combined with antifreeze drainage structure. The following types of waterproof and drainage structures are adopted to solve the problem of frost heave caused by the drainage system of the high-altitude cold and rich water tunnel and the accumulation of water behind the lining. And the problem that affects the use. High altitude generally refers to areas with an average altitude of more than 3000m, and severe cold generally refers to the coldest month of winter with an average temperature of less than -15°C.

[0036] 1. The tunnel is divided into the entrance section and the deep buried section of the tunnel body according to the buried depth. The entrance section of the tunnel is 300m inward from the entrance of the tunnel; the rest are sections of the tunnel body, such as figure 1 Middle section 1-2 is the entrance section, and section 2-4 is the cave body sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com