Constant-speed continuous silicone oil restraining device and method

A technology of restraint device and silicone oil, which is applied in the field of laser processing and laser warm shot peening surface strengthening, can solve the problems that the flexible restraint layer cannot be applied, and the liquid spray system cannot be applied to the delivery of high-viscosity silicone oil, etc., so as to achieve low manufacturing and maintenance costs, Improve reliability and stability, and ensure the effect of restraint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

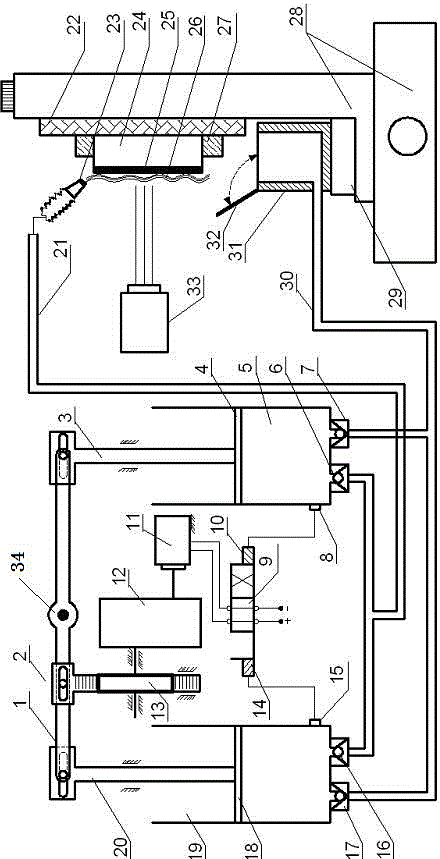

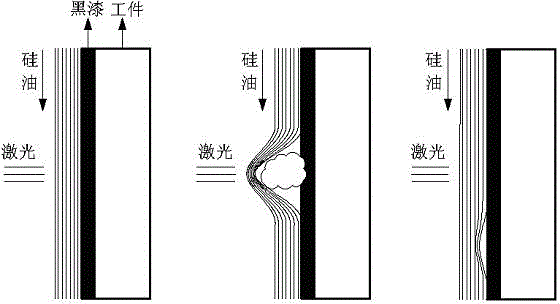

Method used

Image

Examples

experiment example

[0043] Take aluminum alloy A356 as an example. The experiment is divided into two groups, each group contains a 10mm×10mm×2mm square sample.

[0044] In the first group of experiments, the square sample was placed horizontally on the workbench, and the sample was subjected to single-point laser warm shot peening using a static silicone oil with a thickness of 3 mm as a constrained layer, and the sample was impacted twice continuously with an interval of 0.2 s. The laser 33 is a Nd:YAG solid-state laser, and the parameters are as follows: the energy is 2J, the spot diameter is 2mm, the temperature is 150°C, and the pulse width time is 8ns.

[0045] In the second group of experiments, the square sample was placed vertically on the workbench 28, and the sample was subjected to single-point laser warm shot peening using uniform flow of silicone oil as the constrained layer. The sample was impacted twice continuously with an interval of 0.2 s. The thickness of the flowing silicone ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com