Treatment method of organic silicon low-boiling-point substance

A processing method and technology of low boilers, applied in the directions of silicon organic compounds, preparation with chlorides, chlorine/hydrogen chloride, etc., can solve problems such as immaturity, and achieve the effect of high market value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

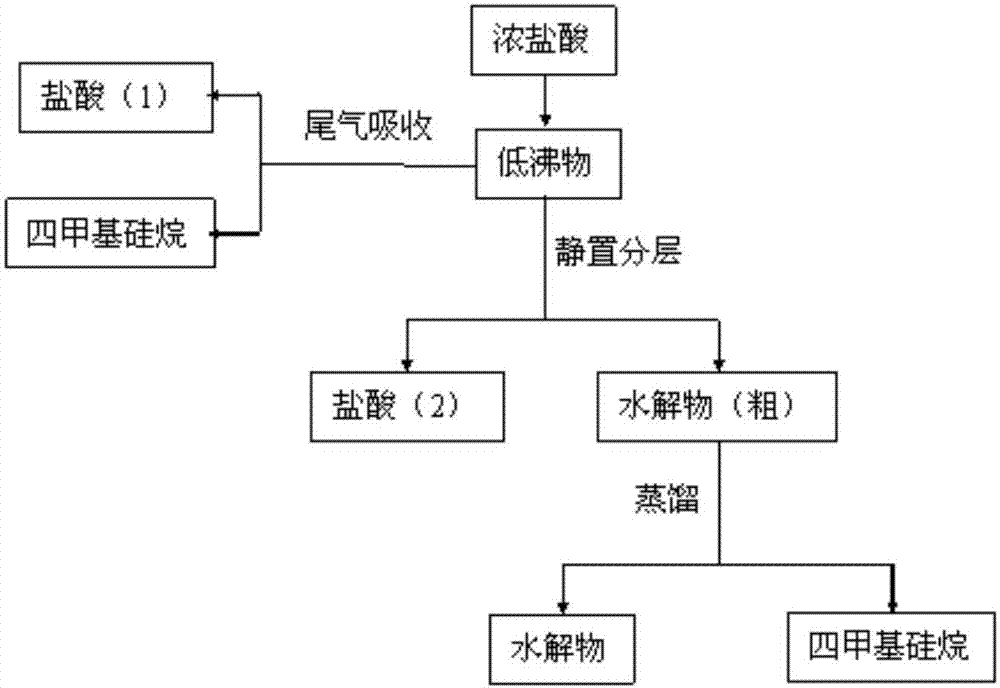

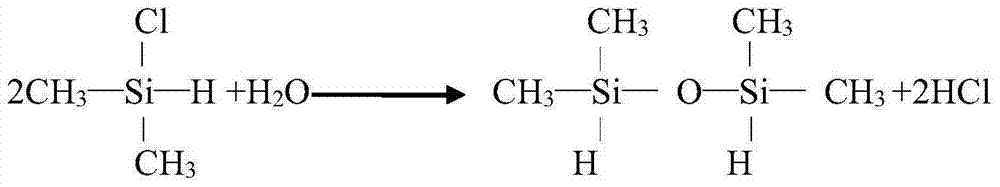

Method used

Image

Examples

Embodiment 1

[0032] The organic absorption solvent is alcohol, the concentration of concentrated hydrochloric acid is 35%, the condensation temperature of the tetramethylsilane condensation absorption device is -10°C, the reaction kettle is a ceramic stirring tank, the aspect ratio of the packing column is 10:1, and the outside of the packing column is equipped with Heat exchange device, when concentrated hydrochloric acid is added dropwise, water at room temperature is passed into the heat exchange device for heat exchange.

[0033] Add 500 volumes of organic silicon low boilers into the reaction kettle, and add 200 volumes of concentrated hydrochloric acid dropwise from the middle of the packing column while stirring. After 0.5 hours, the temperature in the kettle dropped to -10°C. After feeding for 1.5 hours, the temperature in the kettle rose to 0°C. At this time, 120 volumes of concentrated hydrochloric acid had been added, so the feeding speed was increased, and the remaining 80 volum...

Embodiment 2

[0035] The organic absorption solvent is waste engine oil, the concentration of concentrated hydrochloric acid is 35%, the condensation temperature of the tetramethylsilane condensation absorption device is -10°C, the reaction kettle is a ceramic stirring tank, the length-to-diameter ratio of the packing column is 10:1, and the outside of the packing column is set There is a heat exchange device. When concentrated hydrochloric acid is added dropwise, room temperature water is passed into the heat exchange device for heat exchange.

[0036] Add 500 volumes of organic silicon low boilers into the reaction kettle, and add 300 volumes of concentrated hydrochloric acid from the middle of the packing column while stirring. After 0.5 hours, the temperature in the kettle dropped to -10°C. After feeding for 1.5 hours, the temperature in the kettle became normal temperature. At this time, 200 volumes of concentrated hydrochloric acid had been added, so the feeding speed was accelerated, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com