Modification method for titanium silicate molecular sieve

A titanium-silicon molecular sieve and modification technology, applied in molecular sieve catalysts, chemical instruments and methods, crystalline aluminosilicate zeolites, etc., to achieve the effects of improving hydrophobicity, reducing non-skeletal titanium, and improving surface hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

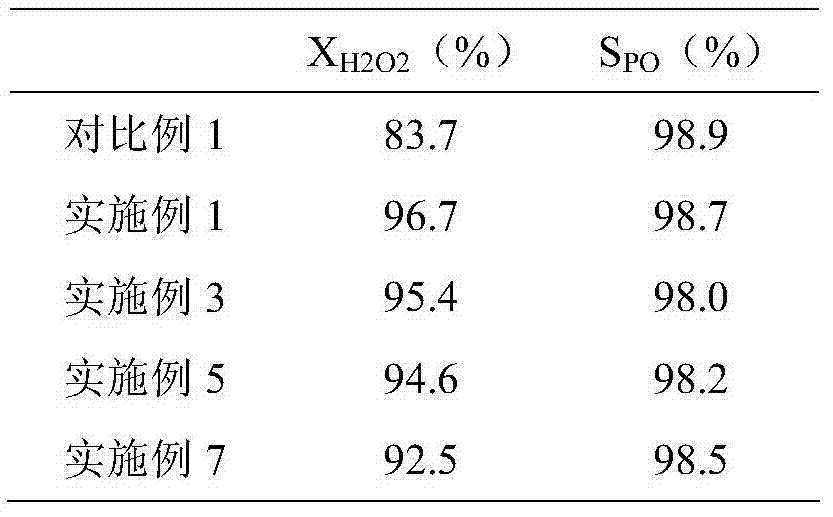

Embodiment 1

[0039] Take the TS-1 molecular sieve obtained in Comparative Example 1 and mix it evenly according to molecular sieve (g): alkali solution of organic chelating agent (mL) = 1:10, put it into a stainless steel sealed reaction kettle, treat it at 170°C for 96h, and then Methods Filtration, washing and drying to obtain modified titanium silicon molecular sieves. Wherein organic chelating agent is cyclohexanediaminetetraacetic acid, concentration is 0.04mol / L; Alkaline solution is ammoniacal liquor and tetrapropyl ammonium hydroxide mixed alkali solution, and ammoniacal liquor concentration is 0.5mol / L, and tetrapropylammonium hydroxide concentration is 0.06mol / L;

Embodiment 2

[0041] Take the titanium-silicon molecular sieve obtained in Comparative Example 2 and mix it evenly according to molecular sieve (g): alkali solution of organic chelating agent (mL) = 1:10, put it into a stainless steel sealed reaction kettle, treat it at 170°C for 48h, and then follow the conventional method Filter, wash and dry to obtain a modified titanium-silicon molecular sieve. Wherein the organic chelating agent is hydroxyethyl ethylenediamine triacetic acid, the concentration is 0.24mol / L; the alkali solution is the mixed alkali solution of ammonia water and tetrapropyl ammonium hydroxide, the concentration of ammonia water is 3.25mol / L, tetrapropyl ammonium hydroxide The concentration is 0.18mol / L;

Embodiment 3

[0043] Take the titanium-silicon molecular sieve obtained in Comparative Example 1 and mix it evenly according to molecular sieve (g): alkali solution of organic chelating agent (mL) = 1:5, put it into a stainless steel sealed reaction kettle, treat it at 150°C for 96h, and then follow the conventional method Filter, wash and dry to obtain a modified titanium-silicon molecular sieve. Wherein organic chelating agent is ethylenediaminetetraacetic acid, and concentration is 0.25mol / L; Alkaline solution is the mixed alkali solution of ammoniacal liquor and tetrapropyl ammonium hydroxide, and ammoniacal liquor concentration is 1.15mol / L, and tetrapropylammonium hydroxide concentration is 0.06mol / L;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com