Modification method for titanium silicate molecular sieve

A titanium-silicon molecular sieve and modification technology, applied in molecular sieve catalysts, chemical instruments and methods, crystalline aluminosilicate zeolites, etc., to achieve the effects of superior catalytic activity stability, improved diffusion performance, and reduction of non-framework titanium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

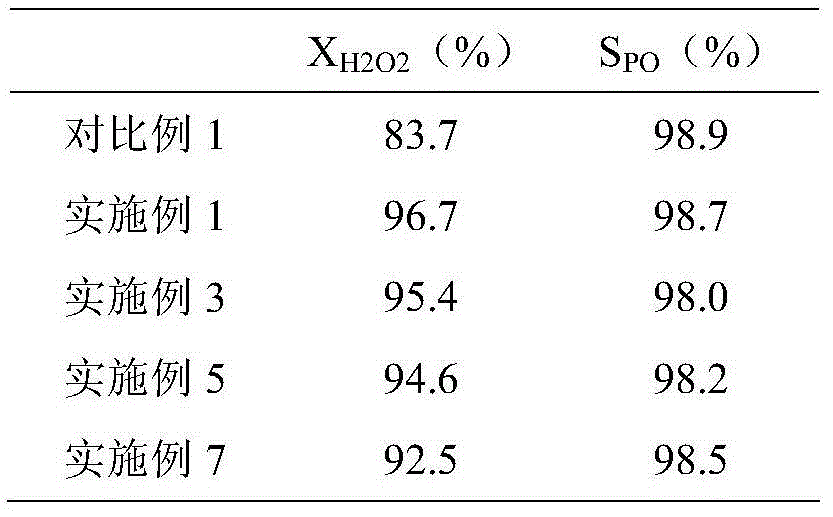

Embodiment 1

[0039] Take the TS-1 molecular sieve obtained in Comparative Example 1 and mix it evenly according to molecular sieve (g): alkali solution of organic chelating agent (mL) = 1:10, put it into a stainless steel sealed reaction kettle, treat it at 170°C for 96h, and then Methods Filtration, washing and drying to obtain modified titanium silicon molecular sieves. Wherein organic chelating agent is cyclohexanediaminetetraacetic acid, concentration is 0.04mol / L; Alkaline solution is ammoniacal liquor and tetrapropyl ammonium hydroxide mixed alkali solution, and ammoniacal liquor concentration is 0.5mol / L, and tetrapropylammonium hydroxide concentration is 0.06mol / L;

Embodiment 2

[0041] Take the titanium-silicon molecular sieve obtained in Comparative Example 2 and mix it evenly according to molecular sieve (g): alkali solution of organic chelating agent (mL) = 1:10, put it into a stainless steel sealed reaction kettle, treat it at 170°C for 48h, and then follow the conventional method Filter, wash and dry to obtain a modified titanium-silicon molecular sieve. Wherein the organic chelating agent is hydroxyethyl ethylenediamine triacetic acid, the concentration is 0.24mol / L; the alkali solution is the mixed alkali solution of ammonia water and tetrapropyl ammonium hydroxide, the concentration of ammonia water is 3.25mol / L, tetrapropyl ammonium hydroxide The concentration is 0.18mol / L;

Embodiment 3

[0043] Take the titanium-silicon molecular sieve obtained in Comparative Example 1 and mix it evenly according to molecular sieve (g): alkali solution of organic chelating agent (mL) = 1:5, put it into a stainless steel sealed reaction kettle, treat it at 150°C for 96h, and then follow the conventional method Filter, wash and dry to obtain a modified titanium-silicon molecular sieve. Wherein organic chelating agent is ethylenediaminetetraacetic acid, and concentration is 0.25mol / L; Alkaline solution is the mixed alkali solution of ammoniacal liquor and tetrapropyl ammonium hydroxide, and ammoniacal liquor concentration is 1.15mol / L, and tetrapropylammonium hydroxide concentration is 0.06mol / L;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com