A guide assembly method of oblique punching slider

An assembly method and slider technology, applied to metal processing equipment, perforating tools, manufacturing tools, etc., can solve the problems of low assembly efficiency, labor and time, and high work intensity, so as to improve efficiency, reduce costs, and reduce work intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

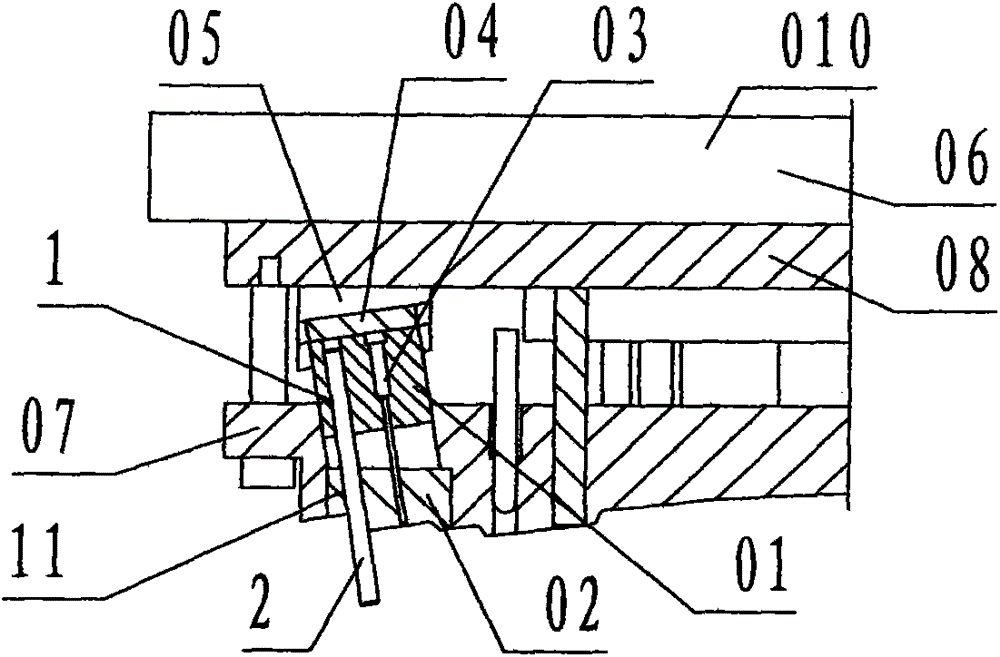

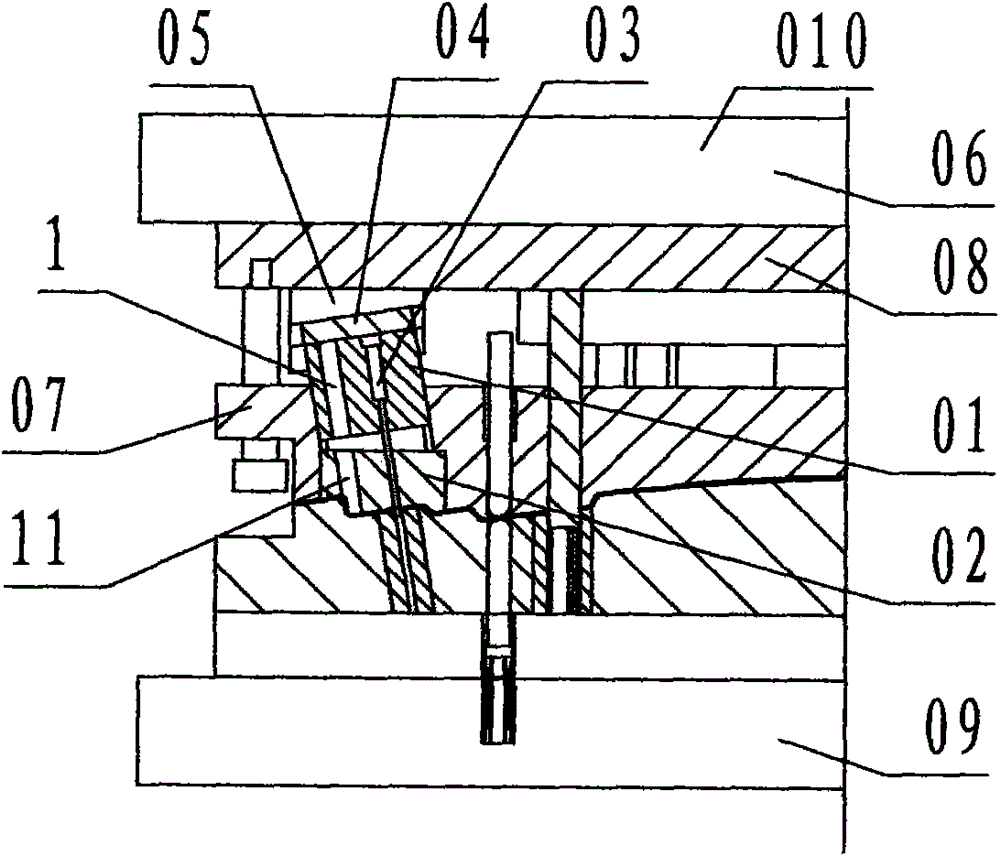

[0019] refer to figure 1 , figure 2 , a guide assembly method for an oblique punching slider of the present invention, including a guide process device and a guide assembly method, wherein: the guide process device includes A guide hole 1, B guide hole 11, guide pin 2, and the The A guide hole 1 is a circular through hole arranged in the punch fixing block 01; the B guide hole 11 is a circular through hole arranged in the punch guide block 02; the A guide hole 1, B The diameters of the guide holes 11 are the same, and the axes of the A guide hole 1 and the B guide hole 11 coincide on the same straight line and are parallel to the central axis of the punch placement hole in the punch fixing block 01;

[0020] The guide pin 2 is a cylindrical steel member, and the guide pin 2 is slidingly matched with the A guide hole 1 and the B guide hole 11;

[0021] The described guide assembly method is:

[0022] Step 1. From top to bottom, put the punch 03 into the punch placement hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com