Hydrophilic active carbon modified by sodium acetate and preparation method thereof

A technology of activated carbon and sodium acetate, applied in the field of hydrophilic activated carbon and its preparation, synthesis of hydrophilic organic functional groups, can solve the problems of activated carbon pore structure damage, activated carbon quality loss and other problems, achieve good reuse, improve adsorption capacity, capillary The effect of increased adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

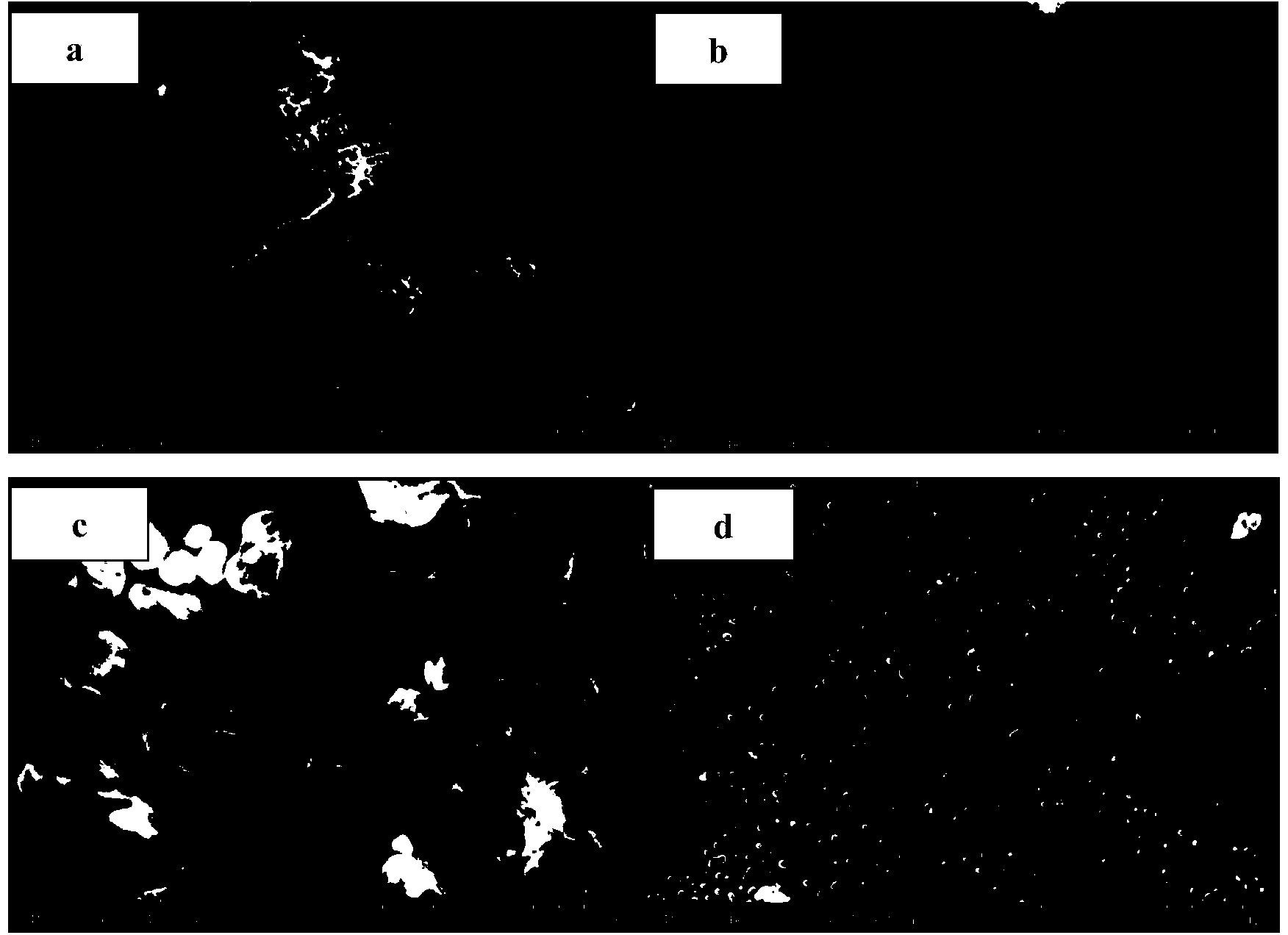

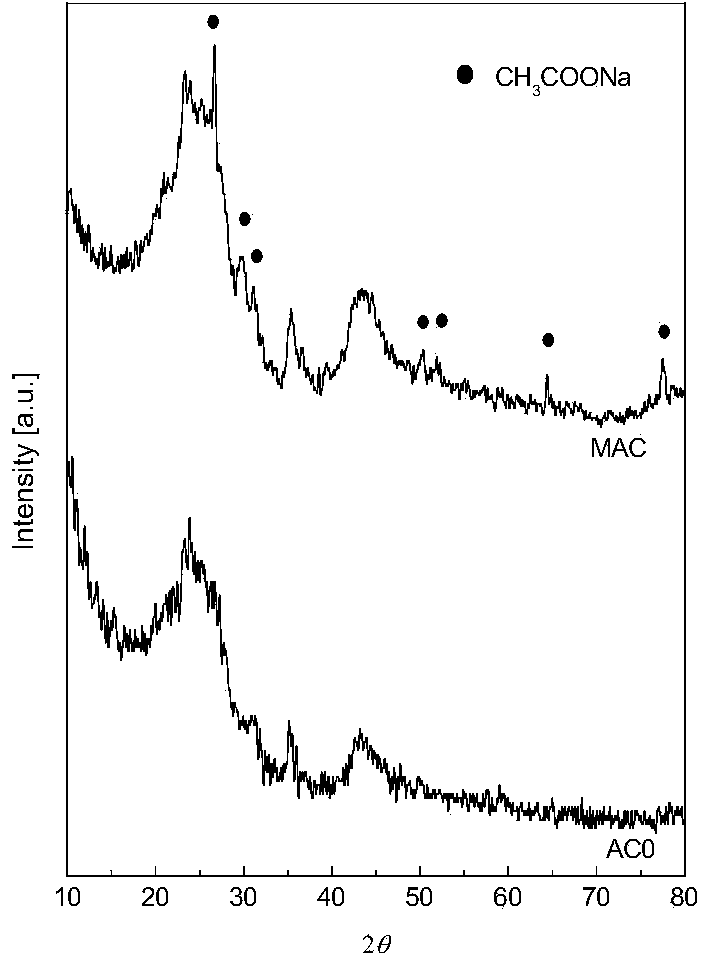

[0028] 1) Preparation of hydrophilic activated carbon

[0029] 100 g of ordinary commercial activated carbon was weighed with a balance and put into a beaker, washed 5 times with distilled water, and dried under vacuum at 125 °C for 12 h. Afterwards, the temperature of the vacuum furnace was raised to 800 °C and maintained for 1 h to remove the existing active groups on the surface of the activated carbon. Measure 1000mL of saturated sodium hydroxide solution, soak the activated carbon in the lye, seal it, let it stand for 5 days, wash it with deionized water 6 times, and dry it under vacuum at 120°C for 18h. The activated carbon was activated at 400°C under vacuum for 1.5h, and when it was naturally cooled to room temperature, it was soaked in ethyl acetate reagent, sealed and left to stand for 4 days. The ethyl acetate reagent was separated from the activated carbon by a gauze filter, and the activated carbon was reacted at 70° C. under vacuum for 20 h. The treated activat...

Embodiment 2

[0036] 1) Preparation of hydrophilic activated carbon

[0037]100 g of ordinary commercial activated carbon was weighed with a balance and put into a beaker, washed 5 times with distilled water, and dried under vacuum at 110 °C for 24 h. Afterwards, the temperature of the vacuum furnace was raised to 950 °C and maintained for 0.5 h to remove the existing active groups on the surface of the activated carbon. Measure 1000mL of saturated sodium hydroxide solution, soak the activated carbon in the lye, seal it, let it stand for 96h, wash it with deionized water 6 times, and dry it under vacuum at 110°C for 24h. The activated carbon was activated at 450°C under vacuum for 1 hour, and when it was naturally cooled to room temperature, it was soaked in ethyl acetate reagent, sealed, and left to stand for 120 hours. The ethyl acetate reagent was separated from the activated carbon by a gauze filter, and the activated carbon was reacted at 85° C. under vacuum for 18 h. The treated act...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com