Multi-stage structure molecular sieve hollow microsphere, preparation methods and application

A technology of hollow microspheres and molecular sieves, which is applied in the field of molecular sieves, can solve the problems of not being able to meet the requirements of high acidity strength for catalytic reactions, weak mechanical strength of multi-level structures, and restricted channel shape selection, etc., to achieve wide application range and strong acidity , no quality loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The tetrapropylammonium hydroxide solution with a mass fraction of 10% was mixed with tetraethyl orthosilicate at a mass ratio of 1:0.3 for 3 hours, and then precrystallized at 100° C. for 48 hours to obtain ZSM-5 molecular sieve seed crystals. Mix ZSM-5 molecular sieve seed crystals, amorphous silica microspheres (0.5 μm outer diameter) and sodium metaaluminate at a mass ratio of 0.1:1:1.7 for 3 hours to make the ZSM-5 molecular sieve crystal seeds evenly adhere on the surface of silica microspheres. Then, the silica microspheres adhered with ZSM-5 molecular sieve seeds were dried at 120° C. for 0.2 hour to obtain dry powder.

[0037] Place a bracket whose height is 3 times the diameter of the hydrothermal kettle in a hydrothermal kettle with a polytetrafluoroethylene liner, and pour a certain amount of water to control the amount of water added to only submerge the bracket. A small container is placed above the support, and the resulting dry powder is put into the sm...

Embodiment 2

[0041] After mixing tetrapropylammonium hydroxide solution with a mass fraction of 50% and tetraethyl orthosilicate at a mass ratio of 1:5 for 1 hour, precrystallization was performed at 100°C for 144 hours to obtain ZSM-5 molecular sieve seed crystals. Mix ZSM-5 molecular sieve seed crystals, amorphous silica microspheres (outer diameter 0.5 μm) and sodium metaaluminate at a mass ratio of 1:10:0.04 for 0.3 hours to make ZSM-5 molecular sieve seed crystals evenly adhere Silica microsphere surface. Then, the silica microspheres adhered with ZSM-5 molecular sieve seeds were dried at 100° C. for 3 hours to obtain dry powder.

[0042] Place a bracket with a height of 0.3 times the diameter of the hydrothermal kettle in a hydrothermal kettle with a polytetrafluoroethylene liner, and pour a certain amount of water to control the amount of water added to only submerge the bracket. Place a small container above the stand, put the dry powder into the small container so that the water ...

Embodiment 3

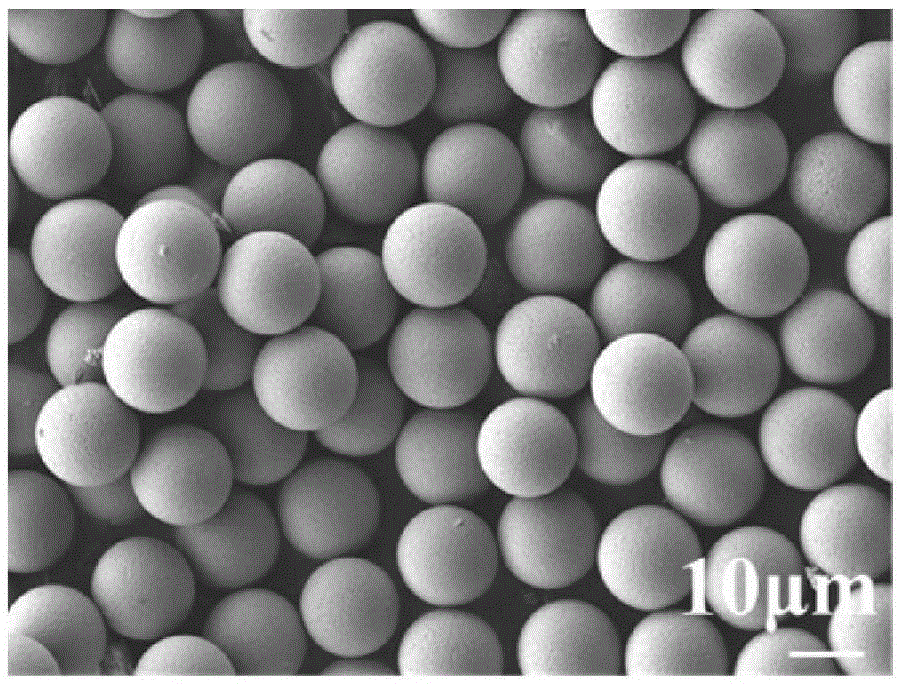

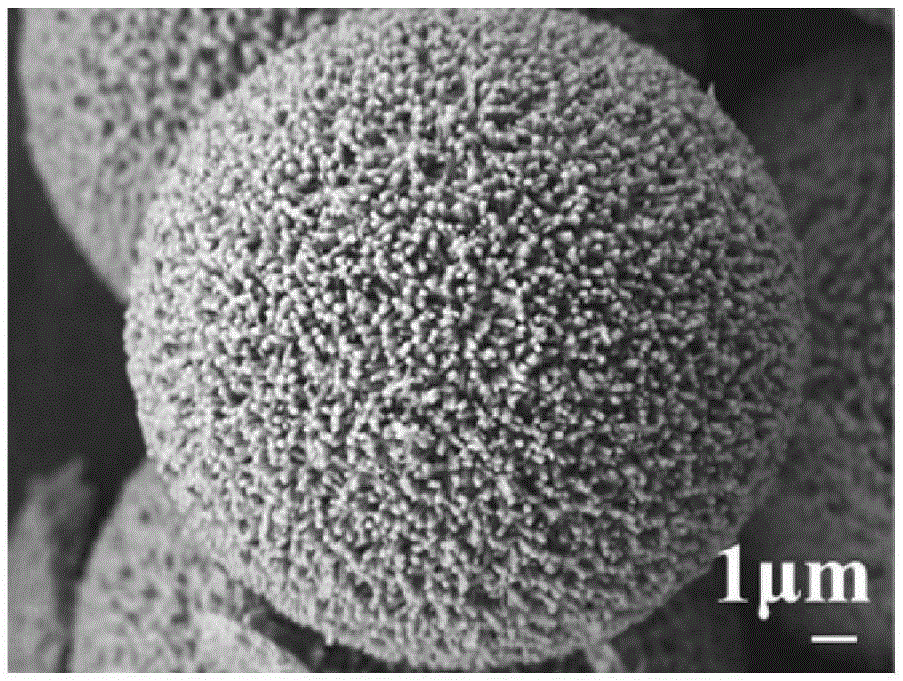

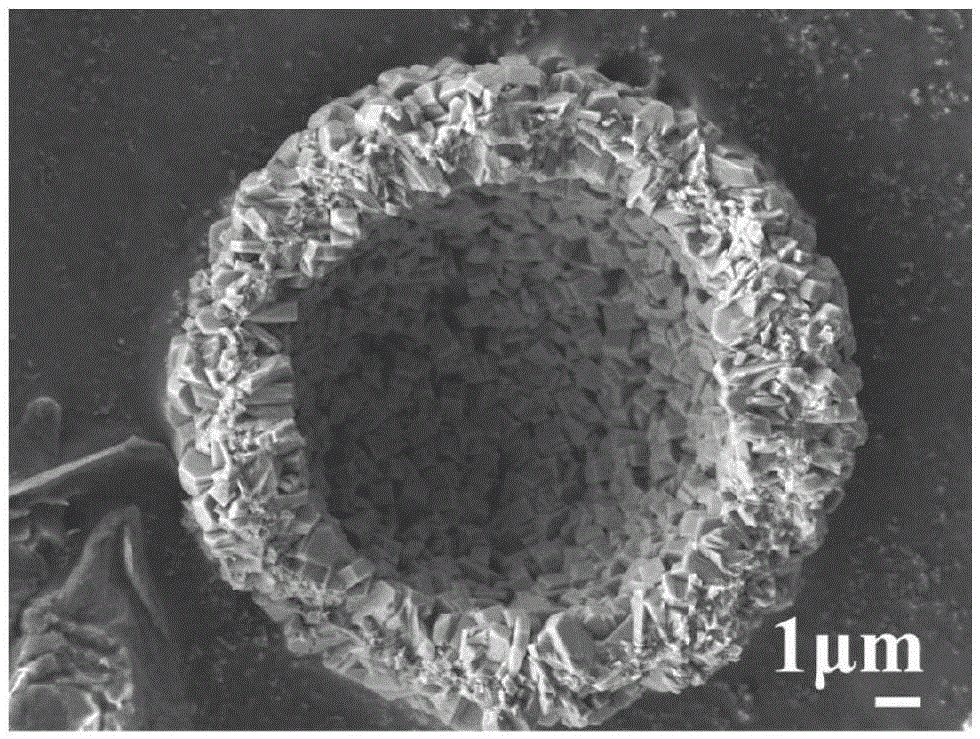

[0046] After mixing tetrapropylammonium hydroxide solution with a mass fraction of 40% and tetraethylorthosilicate at a mass ratio of 1:1 for 3 hours, precrystallization was performed at 100°C for 72 hours to obtain ZSM-5 molecular sieve seed crystals. Mix ZSM-5 molecular sieve seeds, amorphous silica microspheres (outer diameter 10 μm) and sodium metaaluminate at a mass ratio of 0.5:5:0.8 for 1 hour, so that the ZSM-5 molecular sieve seeds evenly adhere to the Amorphous silica microsphere surface. Then, the silica microspheres adhered with ZSM-5 molecular sieve seeds were dried at 110° C. for 4 hours to obtain dry powder.

[0047] Place a bracket with a height of 1 times the diameter of the hydrothermal kettle in a hydrothermal kettle with a polytetrafluoroethylene liner, and pour a certain amount of water to control the amount of water added to only submerge the bracket. Place a small container above the stand, put the dry powder into the small container so that the water d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com